Rma-303 indirect charge - maintenance, Replacement elements, Vibration noise – Ransburg RMA Indirect A12869 User Manual

Page 54: Turbine maintenance

RMA-303 Indirect Charge - Maintenance

49

LN-9268-11.4

!

W A R N I N G

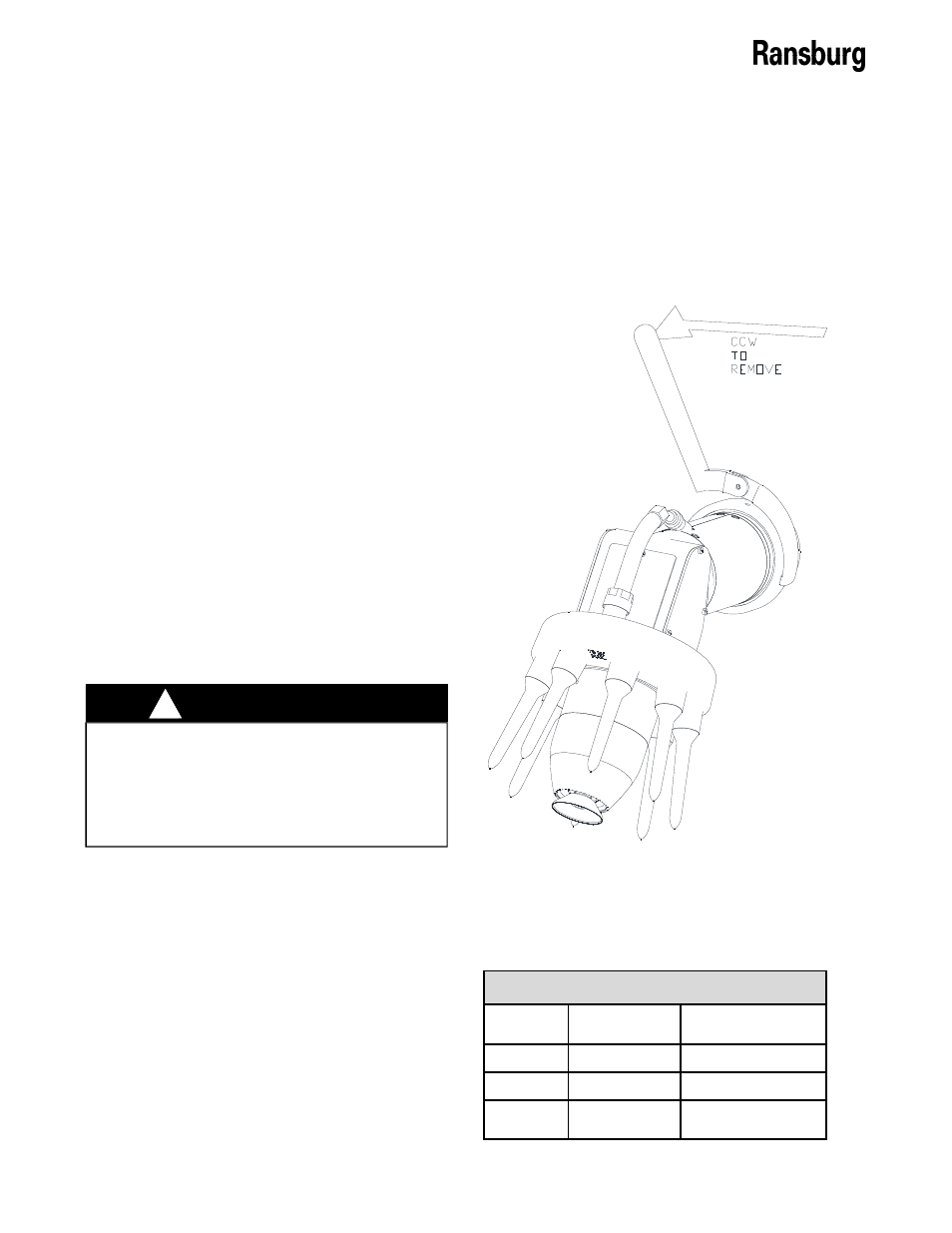

Figure 11: Applicator Removal from Robot

REPLACEMENT ELEMENTS

Part #

Qty. Elements

Per Carton

Used On

HAF-5

1

HAF-515, Pre-Filter

RPM-32

4

RPM-417, Pre-Filter

RPM-33

8

RPM-418, Bearing

Air Filter

VIBRATION NOISE

If the RMA-303 is vibrating or making an unu-

sually loud noise, it usually means there is an

imbalance situation. The atomizer bell cup

may have dried paint on it or the bell may be

physically damaged, or there may be paint

trapped between the bell cup and shaft pre-

venting the bell cup from properly seating. If

any of these conditions exist, they MUST be

corrected. Excessive imbalance caused by

one of these conditions may result in bearing

damage and turbine failure. Warranty DOES

NOT

cover failure caused by imbalanced load-

ing conditions.

To determine if the bell is dirty or damaged,

remove the bell cup and turn the turbine ON.

If the noise is eliminated, the bell cup is the

problem. If the noise continues, the turbine

may be damaged and should be inspected.

Excessive air required to achieve same speed

may indicate a faulty or contaminated turbine.

DO NOT

continue to operate a noisy turbine.

> If a bell cup comes off a rotating shaft be-

cause of motor seizing or any other reason,

the Atomizer and bell cup must be returned to

Ransburg for inspection and evaluation to de-

termine if the bell can be used in operation.

TURBINE MAINTENANCE

DO NOT attempt to rebuild the turbine. Any

endeavor to disassemble a turbine during

the warranty period will void the warranty.

Contact your authorized distributor or

Ransburg for instructions.