Rma-303 indirect charge - maintenance, Disassembly procedures – Ransburg RMA Indirect A12869 User Manual

Page 62

RMA-303 Indirect Charge - Maintenance

57

LN-9268-11.4

> The outer protective cover may have to be

replaced more frequently than weekly. Daily

inspection of the amount of paint buildup on

the cover will determine the frequency of re-

placement.

DISASSEMBLY PROCEDURES

> For re-assembly instructions, use the re-

verse of the following disassembly proce-

dures.

> To facilitate atomizer removal from hose

manifold, a robot program should be made

that purges all paints and solvents from the

RMA-303. Ideally it would then position the

bell assembly in a bell removal position where

the bell cup is pointed downward at a 30° an-

gle. Any residual solvents would be con-

tained in the "J bend" of the robot wrist.

> All O-rings described in the "Maintenance"

section of this manual should be lubricated

with a food grade petroleum jelly or with

A11545 lubricant.

Atomizer Removal/Replacement

> Prior to removing applicator from the robot,

the following tasks must be completed:

•

Robot put into E-stop mode, locked, and

tagged-out.

•

All fluid passages are cleaned, purged

out, and depressurized.

•

Air turned off.

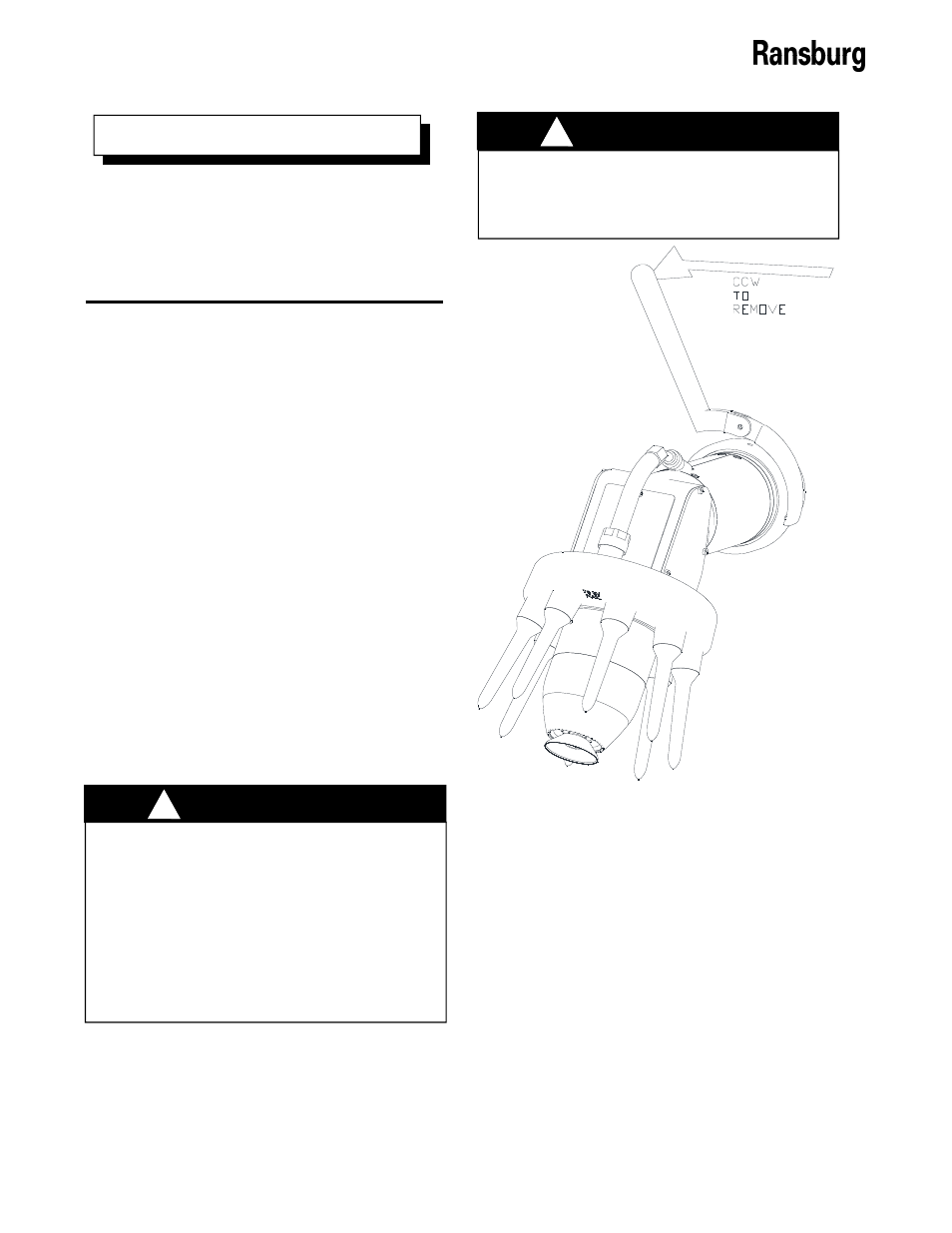

Atomizer Removal

(See Figure13)

Remove rear split shroud by loosening the

flat head retaining screws and pulling the

shroud halves away from the atomizer exten-

sion. Loosen the high voltage nut (78441-00)

that holds the high voltage cable into the

curved high voltage tube. Remove the high

voltage nut and ferrules from the high voltage

cable. Loosen the quick disconnect ring

(A11201-00) with the adjustable spanner

wrench (76772-00) in a counter-clockwise

direction. Pull atomizer away from robot

plate while taking care to feed the high volt-

age cable back through the atomizer.

N O T E

!

W A R N I N G

!

W A R N I N G

Figure 13: Applicator Removal from Robot

> Carefully remove the quick disconnect ring

to insure any residual line pressure has been

relieved to atmosphere.