Mma-303 direct/indirect charge - maintenance – Ransburg MMA-303 Direct_Ind Charge Atomizer A12870 User Manual

Page 98

MMA-303 Direct/Indirect Charge - Maintenance

95

LN-9269-11.3

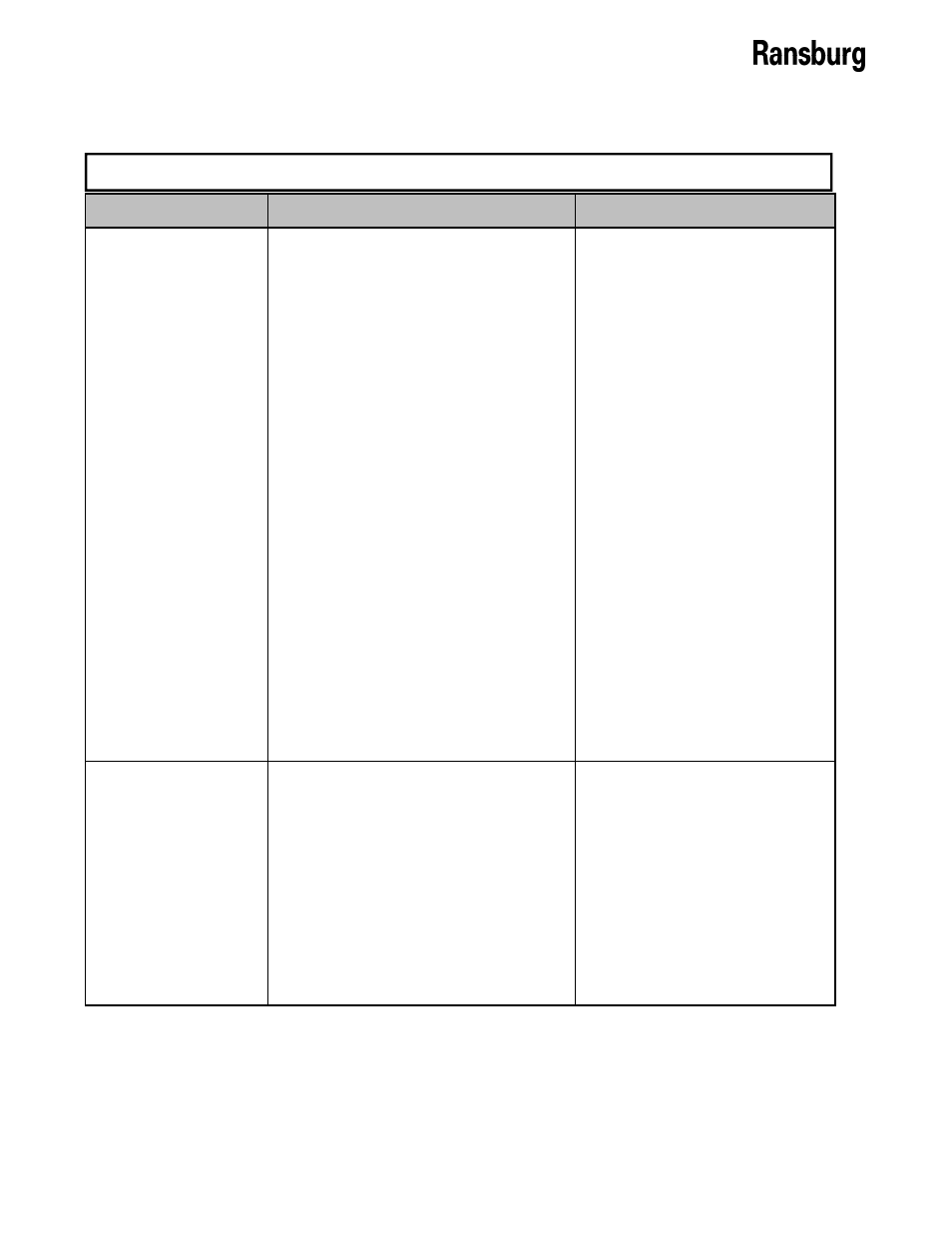

Troubleshooting Guide — Indirect Charge (Cont.)

General Problem

Possible Causes

Corrective Action

Low Transfer Effi-

ciency (or light cov-

erage) (Cont.)

3. Excessive turbine speed

4. Excessive robot speed

5. Excessive inner/outer shaping air

6. Excessive target distance

3. For optimum transfer efficien-

cy and spray pattern control, the

bell rotational speed should be

set at the minimum required to

achieve proper atomization of

the coating material.

4. For optimum transfer efficien-

cy, spray pattern control, bell

speed, and robot speed should

be set at the minimum to achieve

desired results of part to be coat-

ed.

5. Shaping air should be set at

the minimum volume required to

gently direct the spray pattern

toward the part being coated.

Excessive shaping air will cause

some atomized particles to "blow

-by" the part or bounce back on-

to the atomizer.

6. The recommended target

distance is between 6 and 12-

inches (152.4-304.8mm) (see

"Target Distance" in the

"Operation" section of this manu-

al).

No Turbine Air

1. Turbine drive air not present

2. Bearing air return signal not present

3. Brake air is activated

1. Verify supply air pressure.

2. a. Verify bearing air return

signal.

b. Increase bearing air supply

pressure to 90 psig (±10 psig)

(620.5 +/- 69 kPa).

3. Remove brake air signal

(turbine air and brake air must

be interlocked to prevent both

from being used simultaneously).