Mma-303 direct/indirect charge - maintenance, Replacement elements, Turbine maintenance – Ransburg MMA-303 Direct_Ind Charge Atomizer A12870 User Manual

Page 67: General maintenance

MMA-303 Direct/Indirect Charge - Maintenance

LN-9269-11.3

64

one of the conditions may result in bearing

damage and turbine failure. Warranty DOES

NOT

cover failure caused by imbalanced load-

ing conditions.

To determine if the bell is dirty or damaged,

remove the bell cup and turn the turbine ON.

If the noise is eliminated, the bell cup is the

problem. If the noise continues, the turbine

may be damaged and should be inspected.

Excessive air required to achieve same speed

may indicate a faulty or contaminated turbine.

DO NOT

continue to operate a noisy turbine.

!

W A R N I N G

•

If a bell cup comes off a rotating shaft be-

cause of motor seizing or any other reason,

the atomizer and bell cup must be returned

to Ransburg for inspection and evaluation

to determine if the bell can be used in oper-

ation.

TURBINE MAINTENANCE

DO NOT

attempt to rebuild the turbine. Any

endeavor to disassemble a turbine during the

warranty period will void the warranty. The

turbine is non-field serviceable. Contact your

authorized distributor or Ransburg for instruc-

tions.

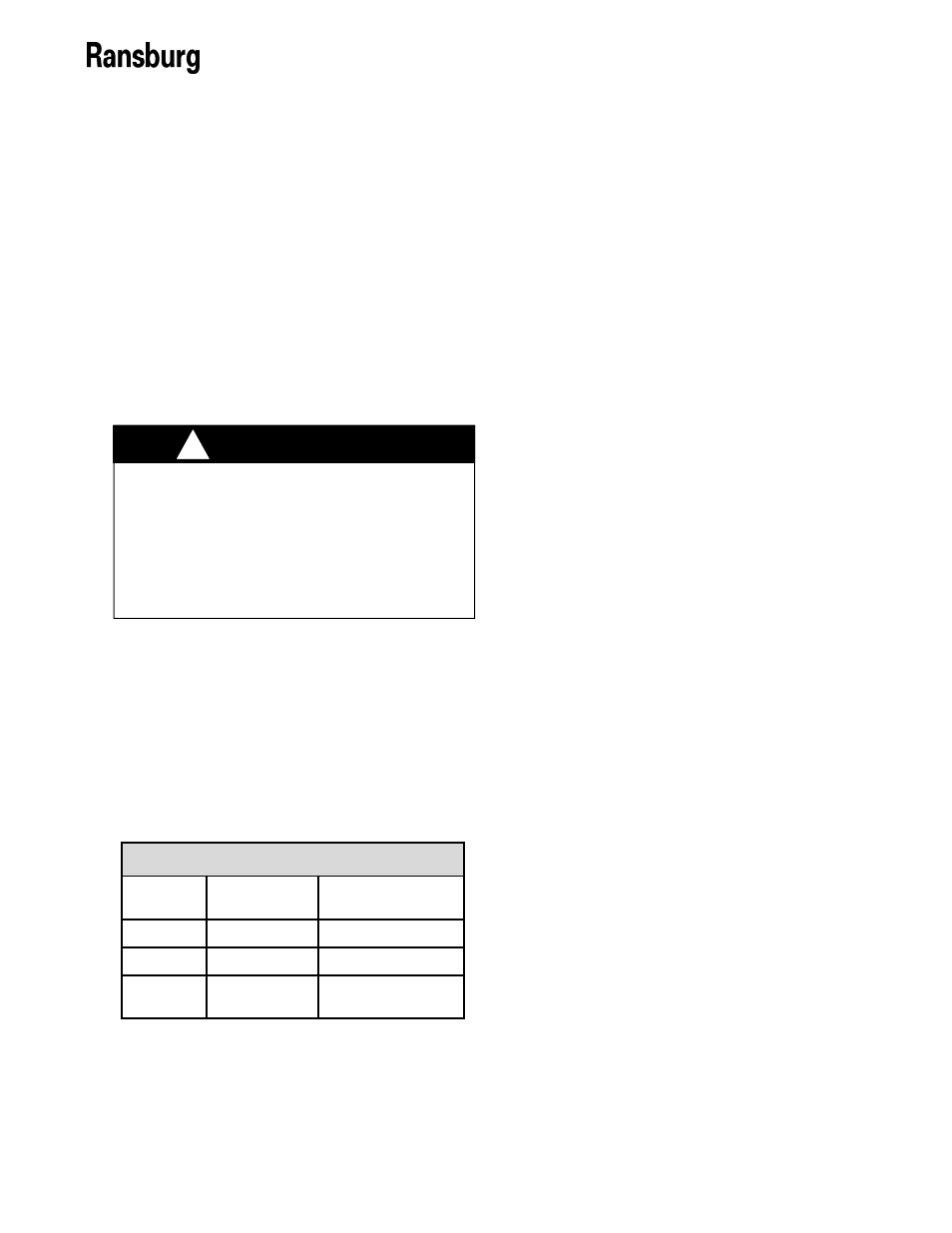

REPLACEMENT ELEMENTS

Part #

Qty. Elements

Per Carton

Used On

HAF-5

1

HAF-515, Pre-Filter

RPM-32

4

RPM-417, Pre-Filter

RPM-33

8

RPM-418, Bearing

Air Filter

GENERAL MAINTENANCE

Verify daily that the operating parameters have

not varied significantly from the normal. A dras-

tic change in high voltage, operating current, tur-

bine air, or shaping air, can be an early indicator

of potential component failure.

A laminated poster entitled “Rotary Atomizer

Checklist” (AER0075-02) is included with the

assembly in the Literature Kit to be posted near

the station as a handy reference.

Due to the close proximity of high voltage to

ground potential, a schedule must be developed

for equipment maintenance (cleanliness).

PREVENTIVE MAINTENANCE

Daily Maintenance (During Each Preventive

Maintenance Break)

1. Verify that high voltage is OFF and that

both inner and outer shaping air, bearing

air, and turbine drive air are ON.

2. Open the dump valve, flushing all paint

from the supply lines and valve module.

3. Open the solvent valve, flushing all paint

from the fluid tube and through the atomiz-

er bell assembly.

4. Re-verify that high voltage is OFF, turbine

drive air is OFF, and that the bell cup has

stopped spinning. The bearing air and

shaping air should remain ON.

5. Clean all external surfaces of the applica-

tor using a lint-free rag dampened with sol-

vent.

6. After cleaning, all conductive residue must

be removed using a non-conductive sol-

vent. Since electrostatic equipment is in-

volved, these solvents should also be non-

polar (Naphtha).