Mma-303 direct/indirect charge - installation, Equipment grounding / safe- ty recommendations – Ransburg MMA-303 Direct_Ind Charge Atomizer A12870 User Manual

Page 44

MMA-303 Direct/Indirect Charge - Installation

41

LN-9269-11.3

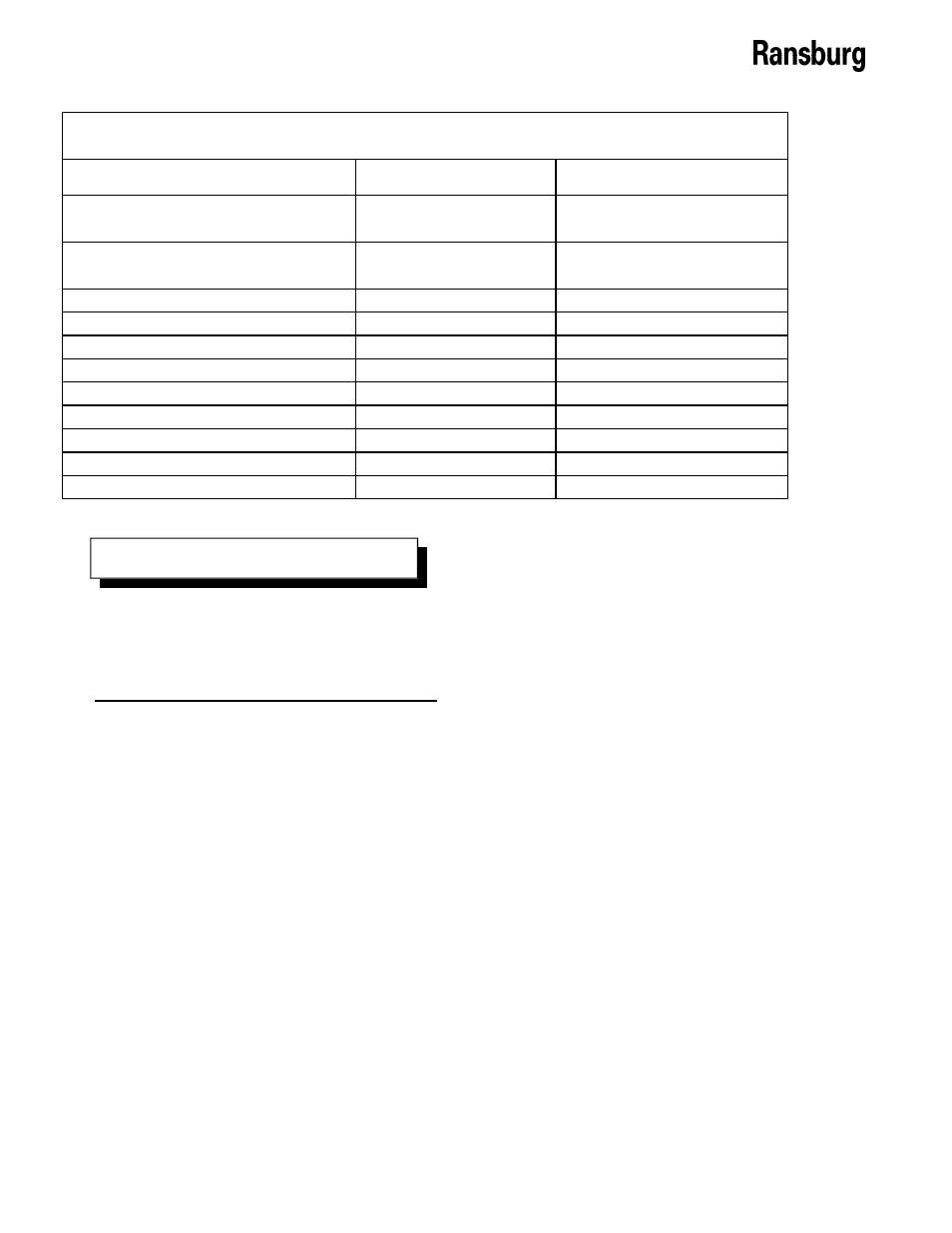

AIR TUBING C0NNECTIONS

Tube Size

Air Pressure Requirements

Bearing Air Supply (B.A.)

6 X 4mm (Yellow)

90 psi +/- 10 kPa)

(621 +/- 69 kPa)

Bearing Air Return (BRG RTN)

4mm (5/32") OD (Yellow)

90 psi +/- 10 (at atomizer card

(621 +/- 69 kPa)

Turbine Air (T.A.)

12 x 10mm

Variable

Cut-In Air (SAO)

10 X 8mm

Variable

Pattern Control Air (SAI)

8 X 6mm (Blue)

Variable

Brake Air (BRK) (if used)

6 X 4mm (Orange)

60-100 psi (414-689 kPa)

Paint Valve Control (PT)

4mm (5/32") OD (Natural)

80 psi +/- 10 (552 +/- 70 kPa)

Dump Valve Control (PD)

4mm (5/32") OD (Gray)

80 psi +/- 10 (352 +/- 70 kPa)

Cup Wash Solvent Valve Control (ST)

4mm (5/32") OD (Blue)

80 psi +/- 10 (352 +/- 70 kPa)

Cup Wash Air Valve Control (ATI)

4mm (5/32") OD (Orange)

80 psi +/- 10 (352 +/- 70 kPa)

Cup Wash Air (CWA)

6 X 4mm (Green)

80-100 psi (551-689 kPa)

N O T E

With the exception of fluid, dump, and bearing

air, all other pilot and air supply lines should

be bulkheaded and their diameters increased

one size.

EQUIPMENT GROUNDING / SAFE-

TY RECOMMENDATIONS

In electrostatic coating systems, the flow of

high voltage power from the power supply to

the atomizer is insulated from ground and iso-

lated from all other functions equipment.

When the voltage reaches the atomizer, it is

transferred to the coating material where, by

introducing a negative charge, it causes the

atomized fluid to seek the nearest positive

ground. In a properly constructed and operat-

ed system, that ground will be the target ob-

ject.

The directed conduction of the electric charge,

through its array of wires, cables, and equip-

ment, is accompanied by a variety of stray

electrical charges passing through the air by

various means such as: air ionization,

charged particles in the air and radiated ener-

gy. Such charges may be attracted to any

conductive material in the spray area. If the

conductive material does not provide a safe

drain to electrical ground, which will allow the

charge to dissipate as fast as it accumulates, it

may store the charge. When its electrical stor-

age limit is reached, or when it is breached by

external circumstances (such as the approach

of a grounded object or person, or one at low-

er potential), it may discharge its stored

charge to the nearest ground. If there is no

safe path to ground (such as a ground wire or

braided cable) it may discharge through the air

as a spark. A spark may ignite the flammable

atmosphere of a spray area. The hazard area

extend from the point of origin up to as much

as a twenty-foot radius. (See the NFPA-33 for

definition and limitations of a hazard area.)