Mma-303 direct/indirect charge - maintenance, Disassembly procedures – Ransburg MMA-303 Direct_Ind Charge Atomizer A12870 User Manual

Page 74

MMA-303 Direct/Indirect Charge - Maintenance

71

LN-9269-11.3

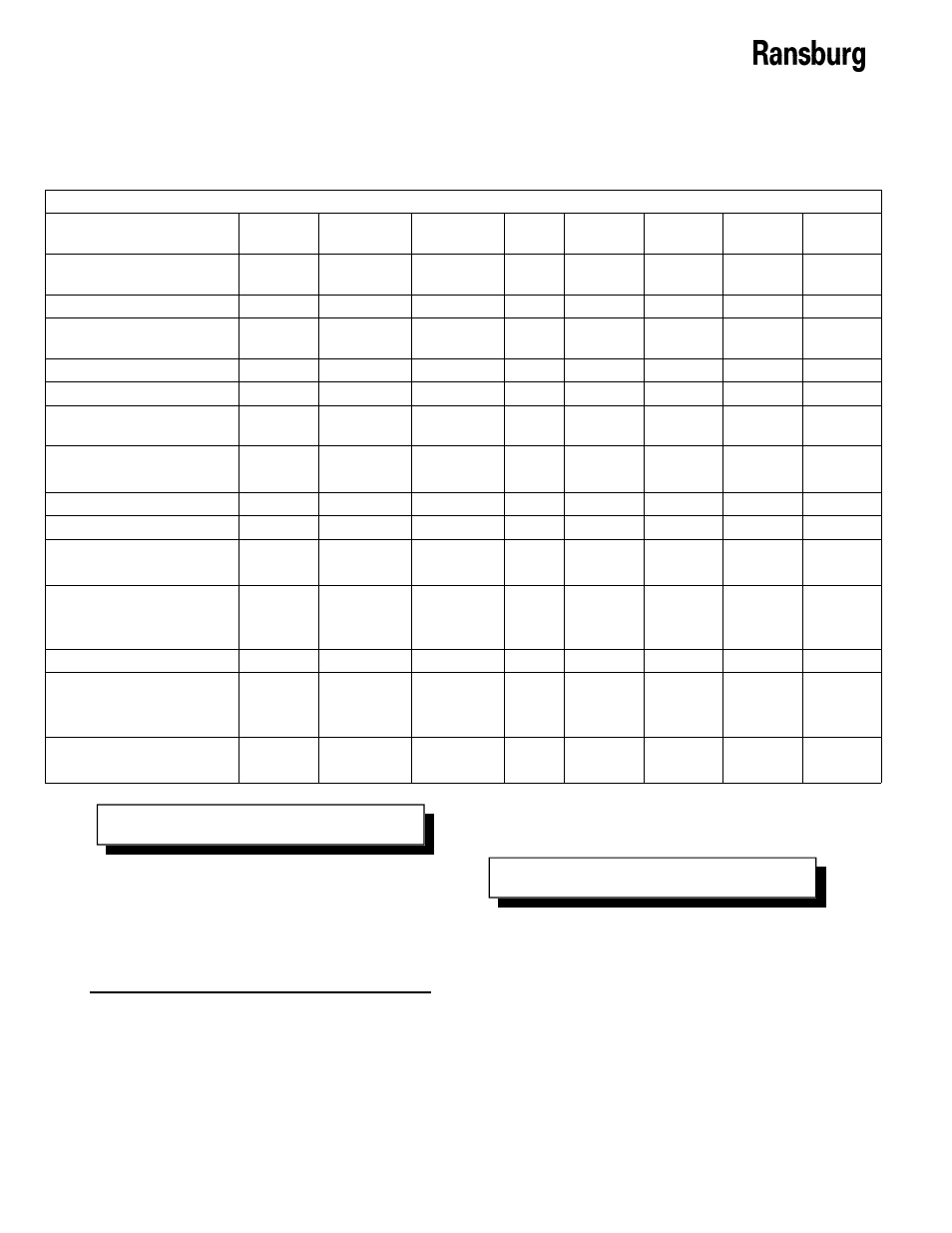

MMA-303 PREVENTIVE MAINTENANCE SCHEDULE (Continued)

Frequency (Maximum)

Procedure

Mid-Shift End of Shift

Weekly

2

Monthly 3 Months 6 Months

Yearly

Inspection of Electrode

X

Replace Electrodes

X

Inspection of Tubing Bun-

X

Regrease Tubing Bundle

X

Replace Tubing Bundle

X

Replace High Voltage Ca-

X

Inspect Turbine Spindle

X

X

taper and threads

Replace Bell Cups

X

X

X

Replace Splash Plates

X

X

Inspect and Clean Spindle

X

X

Bore and Fluid Tube OD

Check High Voltage Con-

X

area for damage/arcing

Inspect for Fluid Leaks

Daily

Check Exterior of High

X

Voltage Ports for degrada-

tion

Check External Cup Flush

X

X

Carbide Tip for blockage

N O T E

NOTE

- The outer protective cover may have

to be replaced more frequently than weekly.

Daily inspection of the amount of paint build-

up on the cover will determine the frequency of

replacement.

DISASSEMBLY PROCEDURES

N O T E

For reassembly instructions, use the reverse

of the following disassembly procedures.

To facilitate atomizer removal from hose mani-

fold, a robot program should be made that

purges all paints and solvents from the MMA-

303. Ideally it would then position the bell as-

sembly in a bell removal position where the

bell cup is pointed downward at a 30° angle.