Mma-303 direct/indirect charge - maintenance, Gap between parts .01" max – Ransburg MMA-303 Direct_Ind Charge Atomizer A12870 User Manual

Page 87

MMA-303 Direct/Indirect Charge - Maintenance

LN-9269-11.3

84

Replacement

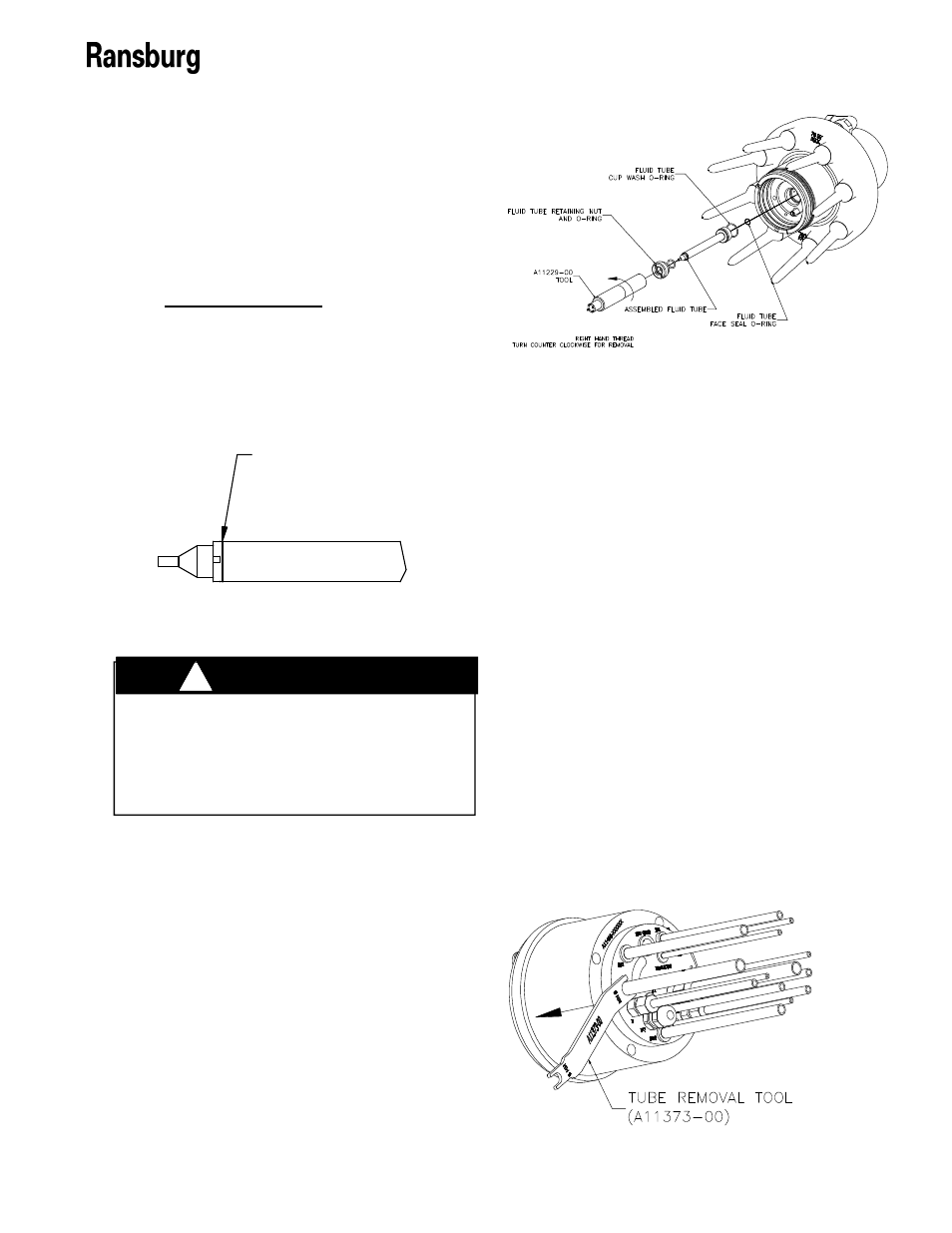

Ensure the tip openings are fully open and

clean. Apply an O-ring lubricant to the O-

ring to help hold it in place on the fluid tip.

Insert the O-ring into the undercut groove on

the tip. Place the tip on the tool and tighten

in a counter-clockwise

direction into the fluid

tube. Do not over-tighten. There will be a

small gap between the flange of the fluid tip and

the fluid tube (see “Fluid Tip/Tube Gap” figure).

Ensure the O-ring is properly positioned when

complete. Tighten to 25-30 lbs•in (2.83-3.4 Nm)

GAP

BETWEEN PARTS

.01" MAX.

Fluid Tip / Tube Gap

!

W A R N I N G

•

When removing fluid tip while turbine is

still installed, make sure to clean paint or

fluid that may leak and run onto the shaft

or threads.

Fluid Tube Removal / Replacement

Removal (Turbine Removed)

Using the fluid tip/tube removal tool (A11229-

00), place the pinned end of the tool towards

the fluid tube retaining nut and engage the pins

into the holes. Turn the tool counter-clockwise

to remove (see “Fluid Tube Removal” figure).

Fluid Tube Removal

Replacement

Lubricate all O-rings with A11545-00 O-ring

lubricant. Push the fluid tube into the pocket

of the atomizer body. Seat the tube by push-

ing while rocking the tube from side to side.

Install the fluid tube retaining nut over the

tube. Tighten the retaining nut firmly tight us-

ing the removal tool in a clockwise direction.

Tighten to 65-75 lbs•in (7.34-8.47 Nm) torque.

Tubing Removal (Mounting End)

Using the tubing removal tool (A11373-00)

select the appropriate size end for the tube

you want to remove, 8mm or 6mm. Place the

opening around the tube and press down on

the quick release collet. Using your other

hand, pull the tubing from the collet. Remove

all tubing from the collets and also remove the

fluid lines held on with compression nuts.

Fluid Tube Removal