Ransburg, Dynaflow, Programer's manual - introduction – Ransburg DynaFlow Programmers Manual User Manual

Page 32

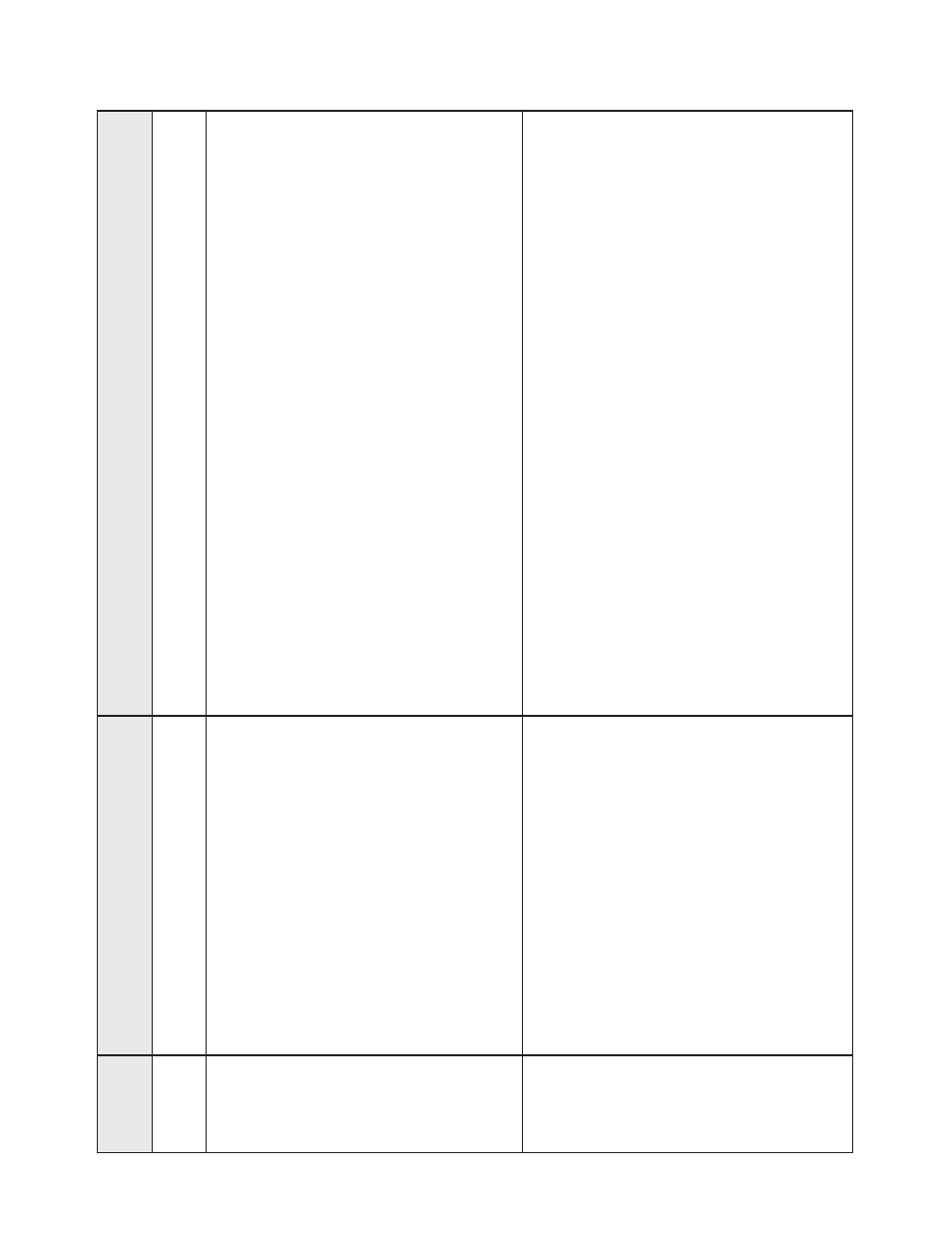

Command Type (hex)

Response Or

Action From User Interface

Response Or

Action From Interface Module

<00>

Re-Send Previous Data

Request for Re-Send of data from Host

<01>

Request for Gun Process data:

<01>

Where: 1)

Response:

<01> Where: 1) , and 4) = Current ratio x 100. 5) = Master Channel actural flow rate in CC/min. 6) . 7) = Slave Channel actual flow rate in CC/min. 8) . 9) Analog set point in CC/min. Note: If all eight (8) Guns are congigured, 120 (8x(1 1+4)) characters must be sent per req- uest. At 19.2 Kbaud, this will require 60 milleseconds. This is the reason for limiting the time between requests to perhaps 100 milliseconds. <02> Request for Job data: <02> Where: 1) and if "A"= 0, Job is inactive. 3) Response: <02> - H> - L> Where: 1) = current ratio x 100. 5) = flow set point in CC's/min. 6) = maximum flow CC's/min. 7) = minimum flow CC's/min. 8) Master Channel V ariables: 9) 28 DynaFlow Programer's Manual - Introduction Ransburg LN-9406-00.3 = Current trigger status, <00> = OFF