General Tools and Instruments 840 Pro Doweling Kit User Manual

Page 9

9. Loosen SLIDE LOCK SCREW (E)

and, starting from the marked

line on board “B”, move the

SLIDE (F) along the SCALE ROD

(G) until the distance the SLIDE

(F) is away from the line is half

the thickness of board “A”. Use

the graduations marked on the

SCALE ROD (G) for measuring (See Figure 11).

Once aligned, tighten SLIDE LOCK SCREW (E).

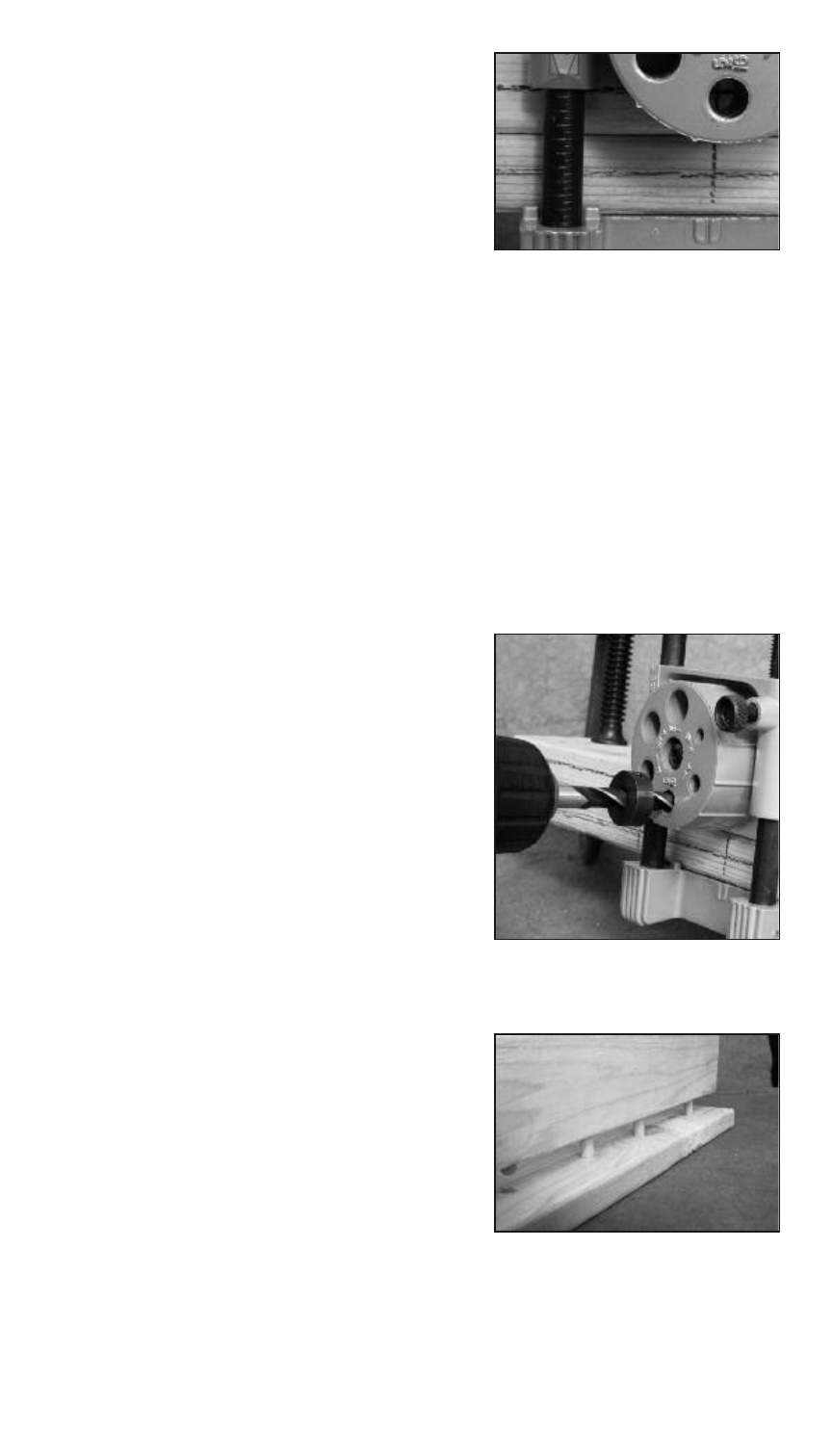

10. Lift TURRET (H) and turn until the correct size hole is

aligned with the INDEX MARK (D). The TURRET (H) will snap

into place when properly located.

11. ENSURE THE DRILL IS TURNED OFF. Place a depth stop

collar on the drill bit at the proper depth to drill the first hole.

NOTE: Position the collar to allow for TURRET (H) height as

well as desired depth of hole.

12. Ensure SLIDE (F) is locked at

proper position and drill dowel

hole in board “B”. The hole in the

TURRET (H) will help you keep

the drill straight (See Figure 12).

13. With clamp in place, loosen the

jig CLAMP SCREW (B) and move

the jig so the next marked

location on the board aligns with

the INDEX MARK (D) on the jig.

14. Gently tighten the CLAMP SCREW

(B) and repeat steps 8-13 until all

dowel holes are drilled.

15. Apply glue to the dowel pins and

insert them in the holes in board

“A” . Align the holes in board “B”

with dowel pins connect boards

“A” and “B” to make the joint

(See Figure 13).

Figure 11

Figure 12

Figure 13

9