Instructions, Edge doweling, Right angle (corner) doweling – General Tools and Instruments 841 User Manual

Page 2

INSTRUCTIONS:

NOTE: In these instructions we will assume using 5/16" diameter dowels,

nominal 3/4" thick boards and drilling with the 5/16" drill bit.

All figure references are on the front & back covers.

EDGE DOWELING:

SETTING THE COLLAR AND DRILL DEPTH

FOR EDGE DOWELING

You will be drilling 3/4" deep dowel holes in each piece

so the 1-1/2" dowels will be equally centered into both

boards. In order to correctly position the drill collar, you

need to add the thickness of the jig plus the length of

the bushing (1") to the 3/4" depth. Thus, to also allow

for gluing, set the collar slightly longer than 1-3/4" from

the end of the drill (Fig. G).

PREPARING YOUR WORK PIECE

1. Draw location lines on the face of your work piece where the dowel holes are to be drilled.

Extend these lines at least 2 inches in from the edge (Fig. H).

2. Select the drill bushing that fits the dowel size you intend to use, and screw it into the long

side of the E•Z Pro Dowel Jig, using the hole that centers on the thickness of the stock

you are using (Fig. I).

3. Secure your work piece and attach the E•Z Pro Dowel Jig to the edge centering the

2" registration line in the appropriate “V” pointer as shown in (Fig. J).

4. Keeping the bushing in the same position re-align jig and drill holes for each dowel

position. Insert dowels, assemble dry to check for fit.

Apply glue to dowel pins or drilled holes for a permanent joint. Once assembled, wipe away

excess glue.

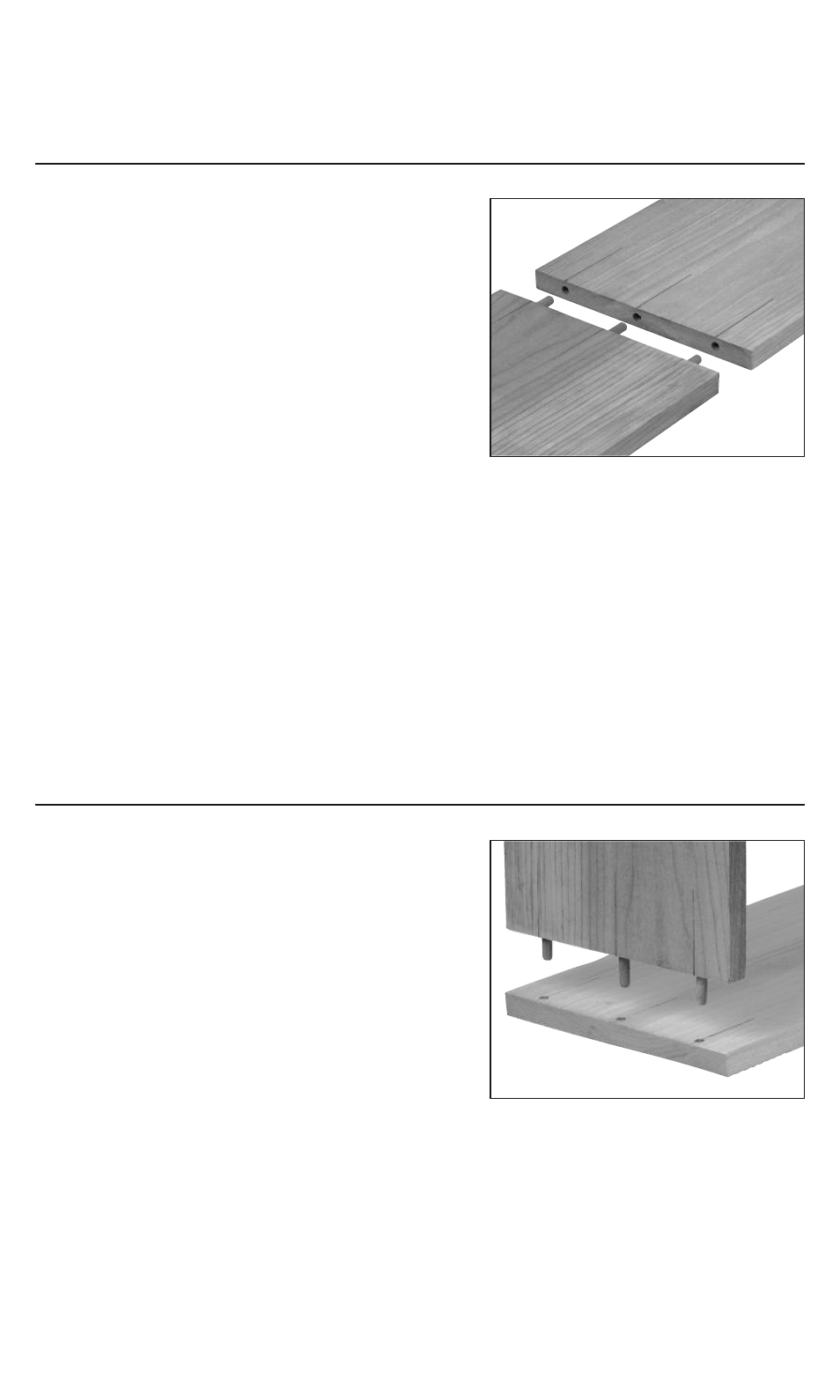

RIGHT ANGLE (CORNER)

DOWELING:

SETTING THE COLLAR AND DRILL DEPTH

FOR RIGHT ANGLE DOWELING

For the edge piece, you will be drilling a 1" deep hole

and/or the surface piece you will be drilling a 1/2" deep

hole to accommodate the 1-1/2" dowels.

Therefore, in order to correctly position the drill collar,

you need to add the thickness of the jig plus the length

of the bushing (1") to the respective depths before

drilling (2" and 1-1/2").

PREPARING YOUR WORK PIECE

Marking the pieces: Lay the 2 pieces to be joined on a flat surface and mark the drill hole

locations across each board (Fig. H). This will be the INSIDE of the joint.

For the edge doweled part:

1. Mark the board and select the appropriate bushing following the edge doweling

instructions (1) and (2) above.

2. Set the appropriate collar depth for edge drilling (2").

3. Drill your edge holes as above (Fig. B).

2