Finish Thompson UC User Manual

Page 14

14

Rear Sealing Ring

The rear sealing ring (item 4C) is located in the rear bore of the barrier assembly (item 6).

Removal

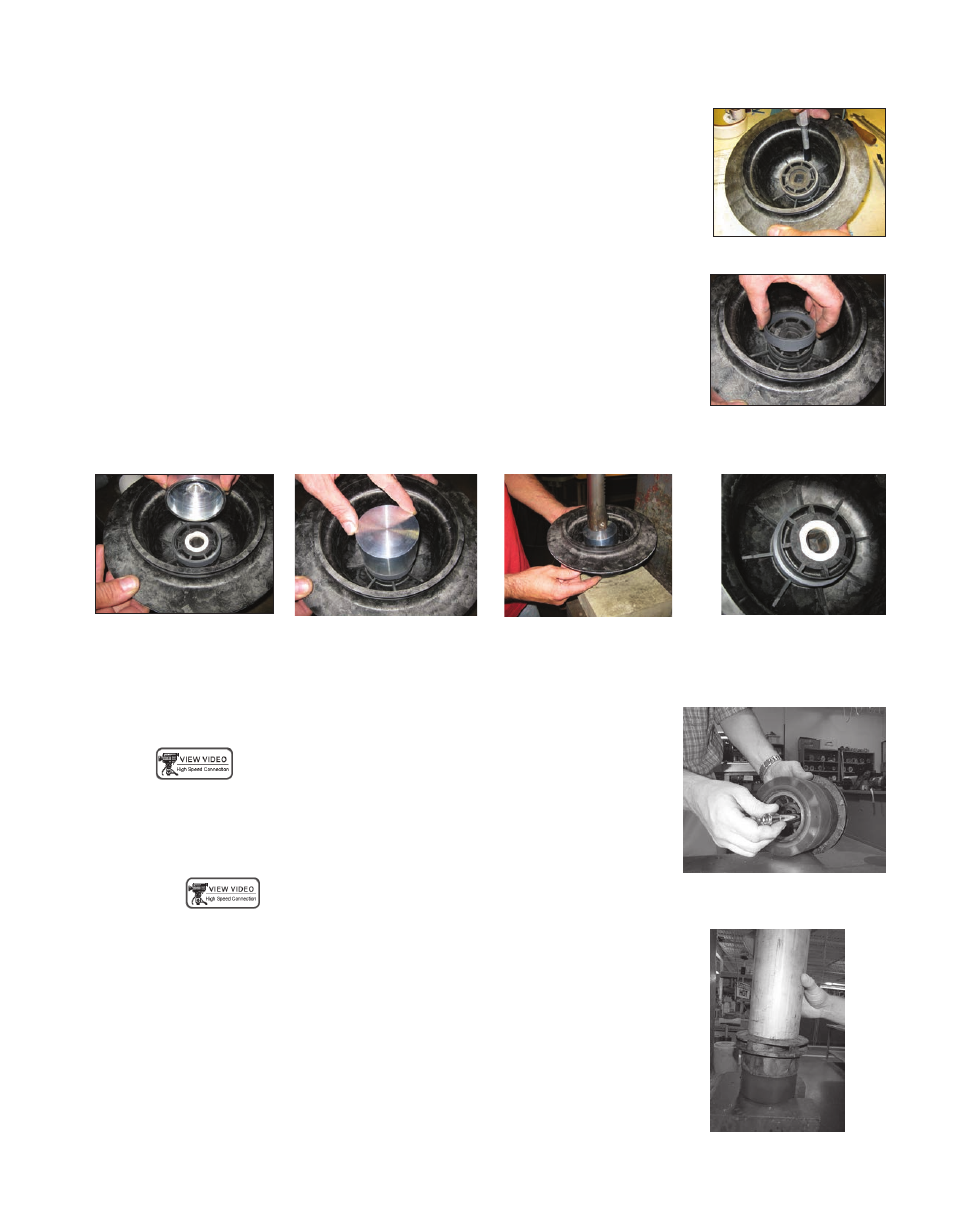

1. Place barrier (item 6) on a table with open side facing up.

2. Remove rear sealing ring by cutting it with a #18 straight edge X-Acto knife or similar blade &

gently cut through the ring. Once cut, simply spread open and remove the ring from the barrier

inner shaft boss. See figure 22.

Replacement

1. Place barrier (item 6) in an arbor press with the open side facing up.

2. Place the rear sealing ring on the inner shaft boss of the barrier assembly, align the two tabs so

they will fit in between the ribs located in the bottom of the barrier. See figure 23.

3. Gently press the ring into place evenly using an arbor press and a 2.68” (68 mm) diameter tool.

Note: this is the minimum inner diameter for the tool to fit over the rear shaft boss. See figures

24, 25, 26.

4. Ring is fully seated when it “snaps” into the machined groove on the boss, roughly 3/8”

(9.5 mm) from the top of the boss. See figure 27.

figure 24

figure 23

figure 22

figure 25

figure 26

figure 27

Impeller Assembly Removal and Replacement

The impeller assembly can be replaced as required to change the impeller diameter or replace

damaged or worn vanes.

Removal

1. Holding the impeller and impeller drive assembly (items 3,3A, 4,4A, 4B, 4C) by hand, place

a 3/8-inch diameter rod (or a 3/8” ratchet extension) through the perforations in the bore of

the impeller drive assembly (item 4).

2. While holding the impeller drive assembly tap on the rod with a hammer in several locations

until the impeller assembly separates from the impeller drive assembly. See figure 28.

Replacement

1. Place the impeller drive assembly in an arbor press with the rear sealing ring facing down.

2. Align the kidney-shaped drive pins on the impeller assembly with the kidney-shaped slots in

the impeller drive assembly and press partially in by hand.

3. Complete installation by pressing the impeller assembly into the impeller drive assembly

with an appropriate size arbor (be sure the arbor does not touch the impeller thrust ring,

item 3A, use an arbor with a larger diameter than the eye of the impeller) until the back side

of impeller rear shroud is flush with front face of impeller drive assembly. See figure 29.

figure 28

figure 29