Disassembly/reassembly – Finish Thompson UC User Manual

Page 11

11

Shutdown

Use the following procedures to shut the pump down.

1. Slowly close the discharge valve .

2. Shut off the motor.

3. Close the suction valve.

Disassembly/Reassembly

Disassembly

Pump End

WARNING: Rotating Parts. This pump has components that rotate while in operation. Follow local safety

standards for locking out the motor from the power supply during maintenance or service.

WARNING: Chemical Hazard. This pump is used for transferring many types of potentially dangerous chemicals.

Always wear protective clothing, eye protection and follow standard safety procedures when handling corrosive or personally

harmful materials. Proper procedures should be followed for draining and decontaminating the pump before disassembly and

inspection of the pump. There may be small quantities of chemicals present during inspection.

WARNING: The pump must be thoroughly flushed of any hazardous materials and all internal pressure relieved prior to

opening the pump.

WARNING: Magnetic force hazard. This pump should only be disassembled and assembled using the recommended

procedures. The magnetic attraction is powerful enough to rapidly pull the motor end and the wet end together. ALWAYS use

the jackscrews (item 14) to assemble/disassemble the pump. Do not place fingers between the mating surfaces of the motor

and wet ends to avoid injuries. Keep the drive magnet and impeller assembly away from metal chips or particles.

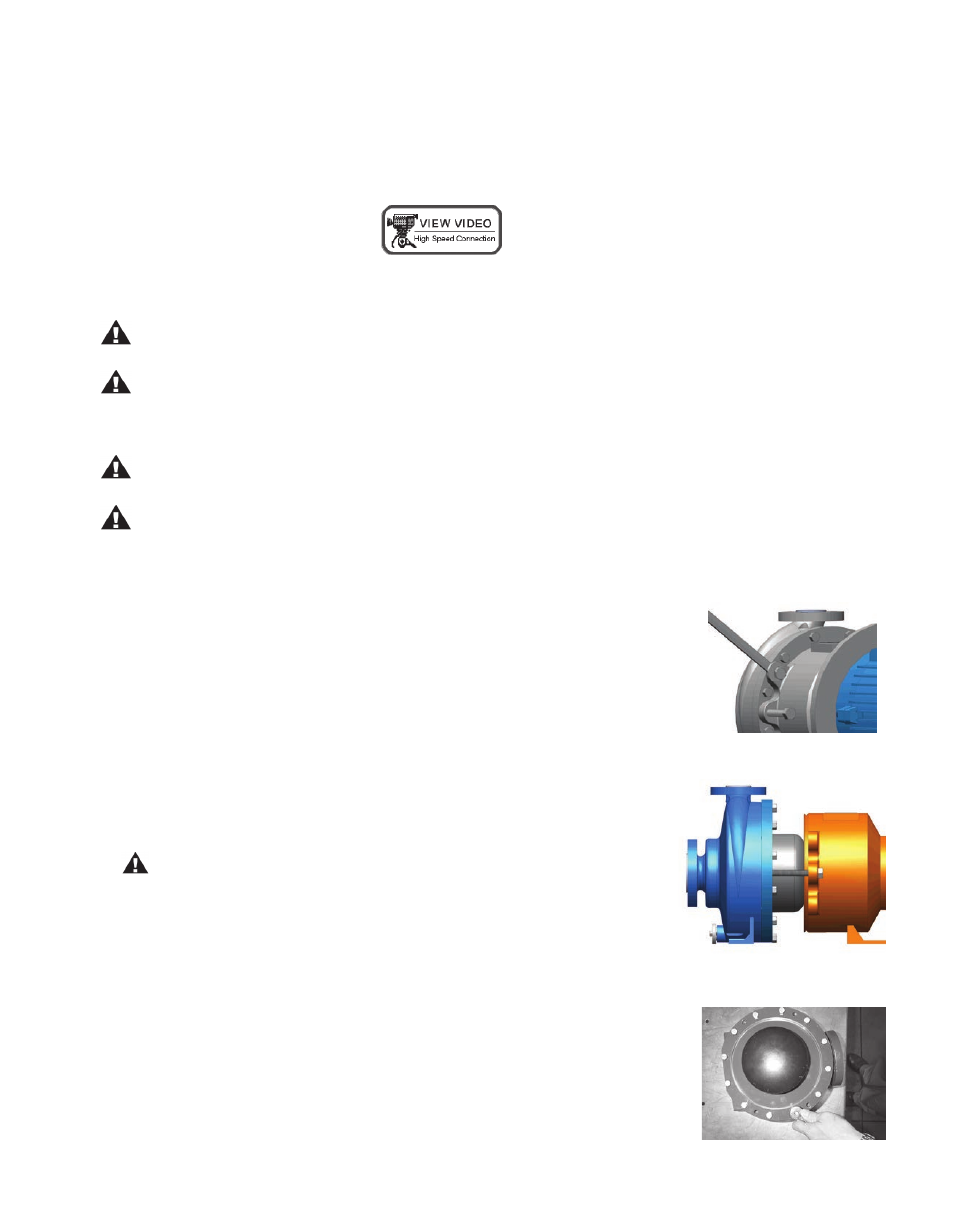

figure 10

figure 11

figure 12

1. Stop the pump, lock out the motor starter, close all the valves that are connected to

the pump, and drain/decontaminate the pump. The ULTRAChem is supplied with a casing

drain to help drain and decontaminate the pump. If the drain flange has been removed to

drain/decontaminate the pump, reinstall the flange (item 11) and use a new gasket (item

11A). Torque the two flange bolts (¼”) (item 11B) to 20 ft-lbs (27.1 N-m).

2. Allow the pump to reach ambient temperatures prior to performing maintenance.

3. Remove the mounting bolts that attach the motor to the base, if any. Using a ¾”

socket, remove the (4) ½” bolts (item 15) that secure the motor adapter (item 9) to the

clamp ring (item 7). See figure 10.

4. Separate the magnetic coupling between the drive end and the pump end by using

the (3) jackscrews (item 14). Using a ¾” socket turn the jackscrews clockwise. Be sure to

turn the jackscrews evenly. Turn the jackscrews until they are fully extended. See figure 11.

CAUTION: After removal of the drive end, the jackscrews should be left fully

engaged in the adapter to prevent accidental attraction of the magnetic coupling.

5. Using a 9/16” socket, remove the (12) 3/8” hex head bolts (item 13) that connect the clamp

ring to the casing (item 1). See figure 12.

6. Remove the clamp ring from the back of the barrier assembly (item 6).

7. Place the casing/barrier assembly on a table with the suction flange of the casing

facing down. Carefully remove the barrier assembly from the casing. It may be necessary to

gently pry with a flat blade screwdriver between the barrier assembly and the casing to help

loosen the o-ring fit. When pulling the barrier assembly out of the casing, the shaft and the

impeller will normally be left in the casing. Occasionally the shaft will stick in the barrier.

If this happens, make sure that the shaft does not drop out when the barrier assembly is

removed or damage may result.