Farm Star MDM70-72C 6 User Manual

Page 41

3

40

D E L I V E RY C H E C K L I S T

Inspect the mower thoroughly after assembly to be cer-

tain it is set up properly. The following checklist is a

reminder of points to inspect. Check off each item as it is

found satisfactory or after proper adjustment is made.

h

Check operator's manual and familiarize the opera-

tor with all sections of it.

h

Check that all safety shielding is in place.

h

Check all bolts to be sure they are tight or adjusted

properly at hinged locations.

h

Check that all cotter pins are properly installed.

h

Check PTO driveline. Make sure it is the correct

length to operate mower with intended tractor.

h

Check that all lubrication points with grease fittings

have been lubricated.

h

Check that blades have been properly installed.

Check all blade beam bolts.

h

Check mower attitude, after mounting on tractor.

h

Check that gearbox is properly serviced and seals

are not leaking.

h

Check shear bolt for proper grade and installation.

h

Check front of input gearbox shaft and make sure

that snap ring is properly installed. (Shearbolt Model)

h

All safety signs (decals) in place and readable.

h

When the cutter is transported on a road or highway

at night or during the day, safety devices should be

used for adequate warning to operators of other

vehicles.

C H E C K L I S T S

I M P O RTA N T !

Gearbox was not filled at factory. It

must be serviced before operating.

Fill to proper level with SAE 90 oil.

Failure to service will result in

damage to gearbox.

P R E - O P E R AT I O N C H E C K L I S T

(OWNER/OPERATOR RESPONSIBILITY)

____ Review and follow safety rules and safety signs on

pages 4 through 16.

____ Check that mower is properly and securely

attached to tractor.

____ Make sure driveline spring-activated locking pin or

locking balls operate freely and are seated firmly in

tractor PTO spline groove.

____ Lubricate all grease fitting locations. Make sure

PTO shaft slip joint is lubricated.

____ Check to be sure gear lube runs out the small

check plug on side of gearbox.

____ Check that all hardware is properly installed.

____ Check to ensure blades are sharp and secure and

cutting edge is positioned to lead in a counter-

clockwise rotation.

____ Check that all shields and guards are properly

installed and in good condition.

____ Check cutting height, front to rear attitude and top

link adjustment.

____ Place tractor PTO and transmission in neutral

before starting engine.

____ Set tractor PTO gear select lever for 540 rpm

operation.

____ Inspect area to be cut and remove stones,

branches or other hard objects that might be

thrown, causing injury or damage.

____ Check that PTO driveline shields are securely

locked and clears the front of the mower frame.

____ Adjust the tractor top link so the front of the mower

is slightly above the rear. Then raise the tractor lift

very slowly, making sure that the front drive shaft

shield does not hit the front of the mower. If it does,

damage will be done to the drive shaft shield and,

if it hits hard enough, it will also damage the drive

shaft itself. (See page 20 – items 9 and 10.)

NOTE: This type of damage is not covered

under warranty, as it is totally under the control

and the responsibility of the operator.

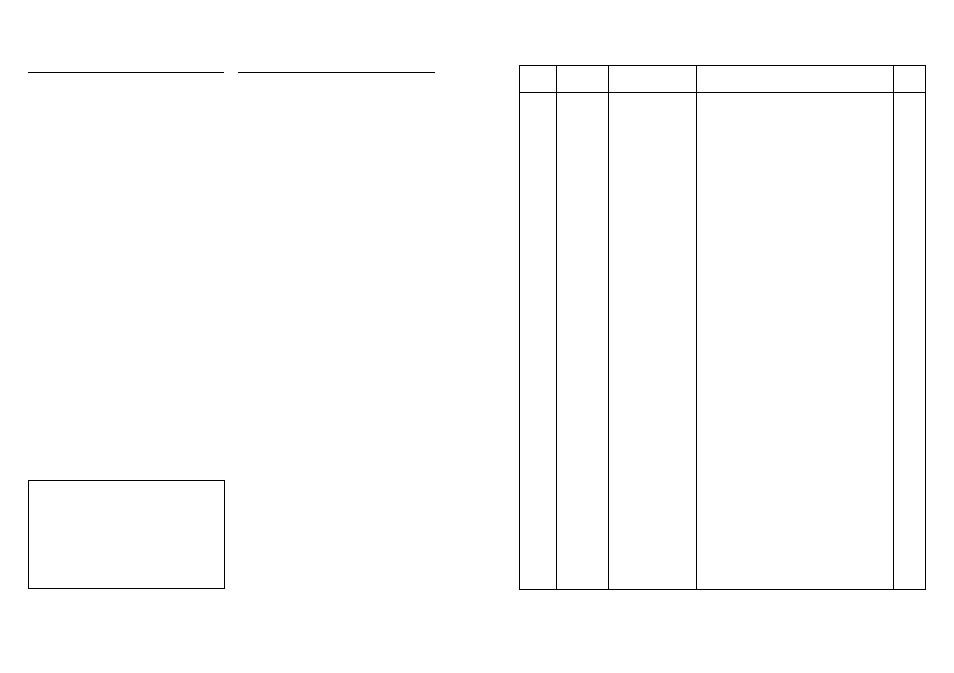

P T O S H A F T ( S H E A R B O LT P R O T E C T E D )

PA RTS LIST

REF.

WORKSAVER

REF. NO.

NO.

PART NO.

(E & G)

DESCRIPTION

QTY.

650479

07.522.064.10

Complete Driveline Assembly (MDM70-60)

1

650470

07.522.066.10

Complete Driveline Assembly (MDM70-72)

1

1

650701

141.025.001

Push Pin Yoke 112

1

2

650702

180.015.130

Cross Journal Set

2

5

650703

151.015.011

Outer Yoke

1

11

650704

190.000.016

Roll Pin for Outer Tube

1

14

650705

152.150.345

Outer Tube (MDM70-60)

1

650729

152.150.337

Outer Tube (MDM70-72)

1

15

650706

153.150.348

Inner Tube (MDM70-60)

1

650730

153.150.349

Inner Tube (MDM70-72)

1

16

650707

190.000.394

Roll Pin for Inner Tube

1

21

650708

151.015.012

Inner Yoke

1

30

650709

151.015.037

Special Yoke

1

31

650710

180.015.009

Guard Retaining Collar for Outer Tube

1

32

650711

180.026.023

Cone for Outer Tube

1

33

650712

190.000.019

Bolt

6

34

650713

156.161.182.7520

Outer Guard (MDM70-60)

1

650731

156.161.345.7520

Outer Guard (MDM70-72)

1

35

650714

157.161.281.7521

Inner Guard (MDM70-60)

1

650732

157.161.444.7521

Inner Guard (MDM70-72)

1

36

650715

158.025.054

Long Cone for Inner Tube

1

37

650716

180.015.008

Guard Retaining Collar for Inner Tube

1

38

650717

180.016.025

Safety Chains

2

40

650718

142.250.028.7520

Complete Guard with Instr. Manual (MDM70-60)

1

650733

142.250.030.7520

Complete Guard with Instr. Manual (MDM70-72)

1

51

650719

166.026.004

Push Pin Set 1

3

/

8

”

1

90

650720

121.025.506.10

U Joint for Outer Tube

1

91

650721

121.025.586.10

U Joint for Inner Tube

1

94

650722

142.251.166.7520

Half Female Guard (MDM70-60)

1

650734

142.251.183.7520

Half Female Guard (MDM70-72)

1

95

650723

142.251.275.7520

Half Male Guard (MDM70-60)

1

650735

142.251.277.7520

Half Male Guard (MDM70-72)

1

96

650724

123.250.731.10

Half Female Shaft with Guarding (MDM70-60)

1

650736

123.250.734.10

Half Female Shaft with Guarding (MDM70-72)

1

97

650725

123.250.426.10

Half Male Shaft with Guarding (MDM70-60)

1

650737

123.250.428.10

Half Male Shaft with Guarding (MDM70-72)

1

98

650726

190.000.098

“DANGER” Label for Outer Tube

1

99

650727

190.000.099

“DANGER” Label for Outer Guard Tube

1

100

650728

190.000.371

Instruction Manual

1