Always obey all safety warnings – Farm Star MDM70-72C 6 User Manual

Page 20

19

24

O W N E R S E RV I C E

The information in this section is written for operators

who possess basic mechanical skills. Should you need

help, your dealer has trained service technicians

available. For your protection, read and follow all safety

information in this manual.

W A R N I N G !

▲

Before working underneath, raise 3-pt. hitch to

highest position and block cutter securely.

Hydraulic system leakdown and failure of

mechanical or hydraulic system can cause equip-

ment to drop.

▲

Keep all persons away from operator control area

while performing adjustments, service or mainte-

nance.

▲

Lower mower to ground or block securely, turn

tractor engine off, remove key and disconnect

mower driveline from tractor PTO before perform-

ing any service or maintenance.

L U B R I C AT I O N I N F O R M AT I O N

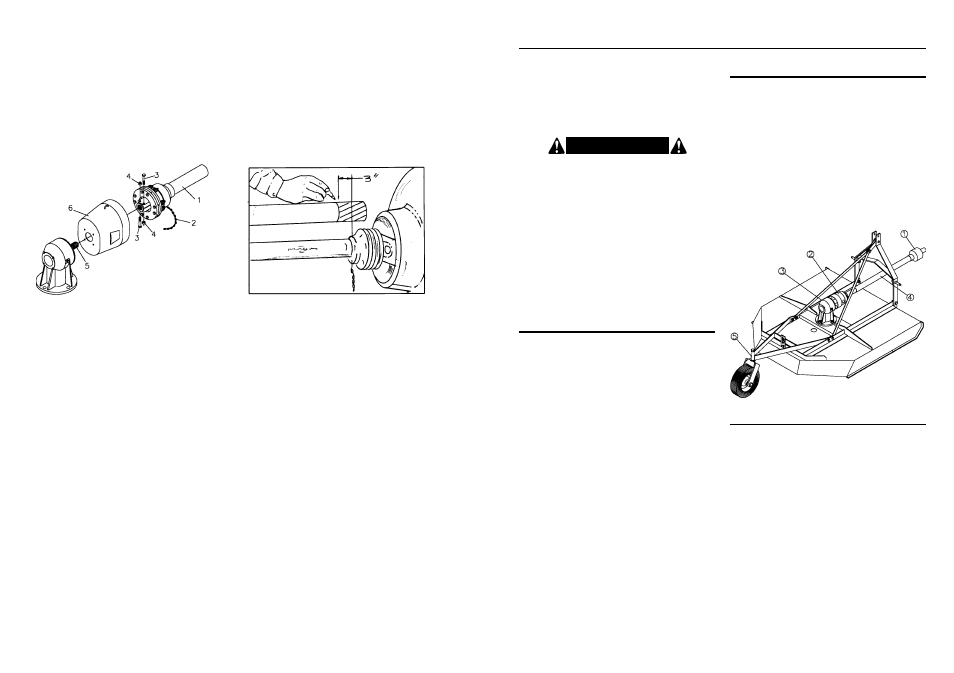

Figure 7 shows the lubrication points. The accompany-

ing chart gives the frequency of lubrication in operating

hours, based on normal conditions. Severe or unusual

conditions may require more frequent lubrication.

Do not let excess grease collect on or around parts,

particularly when operating in sandy areas.

Use an SAE 90W gear lube in gearbox.

Use a lithium grease of NO. 2 consistency with a MOLY

(molybdenum disulfide) additive for all locations. Be sure

to clean fittings thoroughly before attaching grease gun.

When applied according to the lubrication chart, one

good pump of most guns is sufficient. Do not over

grease.

Figure 7.

LUBRICATION CHART

REF NO.

DESCRIPTION

FREQUENCY

1

Front U-Joint

8 Hrs.

2

Rear U-Joint

8 Hrs.

3

Gearbox – Fill to proper level

Check Daily

4

Slip Joint

8 Hrs.

5

Tail Wheel

8 Hrs.

Daily lubrication of the PTO slip joint is necessary.

Failure to maintain proper lubrication can result in

damage to U-joints, gearbox, tractor PTO and/or mower

driveline.

ALWAYS OBEY ALL

SAFETY WARNINGS!!

R O U T I N E M A I N T E N A N C E

DAILY CHECKS:

1. Check that all bolts, nuts, and screws are tight.

Checking the bolts and nuts on the blade beam

assembly is particularly important.

2. Check daily the level of the gearbox oil and top up to

the correct level. Check for gearbox oil leaks. It should

be noted that no warranty claim can be submitted on

a gearbox that has run dry. It is essential that the

gearbox is kept correctly filled with gearbox oil.

3. Grease the PTO shaft daily.

4. Check the wear on the blades. Sharpen them

routinely with an angle grinder or replace when worn

down too far. You should keep at least two sets of

blades, bolts, and nuts as spares for your mower.

AT THE END OF YOUR CUTTING SEASON:

1. Drain and change the oil in your gearbox.

2. Check and replace, where necessary, blades, bolts,

nuts, or bushings, on the machine.

3. Clean machine and touch up any rust spots that may

have appeared.

4. Replace any safety signs if damaged.

5. Store mower in clean, dry location.

Figure 4.

NOTE: The use of a PTO over-running clutch or exten-

sion could require that the PTO driveline be shortened a

considerable amount. If this is done, the driveline halves

may separate when the mower is lowered to the ground

or when operated on rough ground.

NOTE: Because of the above situation, and that the use of

PTO extensions extend the front PTO driveline joint beyond

the protection of the tractor PTO shield, the use of PTO

extensions and over-running clutches of this type are not

recommended.

If your tractor is not equipped with a “Live” PTO and

requires an over-running clutch, check with your dealer

about the availability of special PTO drivelines equipped

with an over-running clutch.

4. Raise and lower the mower to determine position with

greatest distance between the PTO shaft and gearbox

input shaft. Shut tractor off, leaving mower in position

of greatest distance between shafts. SECURELY

BLOCK MOWER IN POSITION.

5. Hold driveline sections parallel to each other and

check for minimum 6” (15cm) overlap. If driveline

has been marked for cutting, overlap will be the

distance between the two marks. If driveline has less

than minimum overlap, do not use. Contact

authorized Worksaver dealer.

I N S T R U C T I O N S

(continued)

1. Drive Shield

2. Tether Chain

3. Bolt

4. Nut

5. Gearbox Input Shaft

6. Gearbox Input Shield

Figure 3.

Optional Slip Clutch Driveline Installation

Align the holes in the driveline yoke and gearbox input

shaft and install bolt (7) and (1).

Lubricate rear driveline half and install front driveline

half.

SLIP CLUTCH MODELS

Optional Slip Clutch Driveline Installation

(Figure 3)

A new slip clutch, or one that has been in storage over

the winter may seize. Before operating, make sure it will

slip. Refer to slip clutch adjustment on page 26.

In some cases it will be necessary to shorten the PTO

assembly to match your particular tractor. The following

procedure should be used:

1. Raise the tractor 3-pt. hitch so the input shaft of the

mower gearbox is in line with the PTO shaft on the

tractor. Shut down tractor, leaving mower in position

of shortest distance between shafts. SECURELY

BLOCK MOWER IN POSITION.

2. Pull driveline apart. Attach outer (female) section to

tractor PTO shaft. Pull on driveline section to be sure

that yoke locks into place.

3. Hold driveline sections parallel to each other to

determine if too long. Each section should end

approximately 3” (76mm) short of reaching universal

joint shield on opposite section. If too long, measure

3” (76mm) back from universal joint shield and mark

on opposite section (Figure 4). Do this for both sec-

tions. DO NOT CUT UNTIL STEPS 4 AND 5 ARE

CHECKED.