Farm Star MDM70-72C 6 User Manual

Page 19

25

18

I N S T R U C T I O N S

(continued)

A T TA C H M E N T

The mower is shipped partially assembled. Assembly

will be easier if components are aligned and loosely

assembled before tightening hardware. Recommended

torque values for hardware are located on page 26.

Select a suitable working area. Refer to illustrations,

accompanying text, parts lists and exploded view

drawings.

Complete check lists on page 20 when assembly is

complete.

Position mower flat and cut the nylon straps that are

holding all loose parts to the mower.

Rotate the “A” frame hitch forward and connect lift arms

and toplink.

Attach the two linkage lift straps to the mower deck

(behind the gearbox) and to the end of the slack link on

the “A” frame. These bolted connections are moveable

joints – so tighten nylock nuts only until excess loose-

ness is gone.

Most swinging drawbars will have to be moved to a

forward position or removed. Check the tractor swing-

ing drawbar for interference with the front of the mower

and PTO driveline before attempting to lift the mower

with the 3-pt. hitch.

Tractor lift arm stabilizer bars or sway blocks must be

used to control side movement of the cutter. DO NOT

CONNECT THE PTO DRIVELINE AT THIS TIME.

Check your lift arm hydraulic controls. Be sure the

hydraulic 3-pt. hitch control is in the float position and the

draft control is turned off.

Adjust lower lift arm(s) to level mower right to left. Refer

to tractor operator’s manual for instructions.

Cutting height is controlled with tractor 3-point arms,

and rear tailwheel adjustment.

PTO DRIVELINE INSTA L L AT I O N

On new mowers, check PTO driveline for correct length

for use with your tractor. (Read page 19.)

SHEARBOLT MODELS

Spray WD-40 into the yoke and wipe. This should

remove some of the paint and make it easier to slide the

yoke onto the input shaft of the gearbox.

Remove shearbolt and retaining ring (4) from gearbox

input shaft (3).

Grease the input shaft of the gearbox before installing

the PTO shaft. This reduces the chance of the PTO shaft

yoke from galling to the input shaft if the shear pin should

break.

Remove rear drive shield (1) from driveline. To remove,

turn each plastic clip

1

/

4

turn and then lift out. Then slide

rear shield so entire joint assembly is exposed. (Refer to

figure 2.)

To prevent seal damage, carefully push driveline onto

gearbox input shaft until it contacts gearbox housing.

Install retaining ring (4) and then pull driveline ahead.

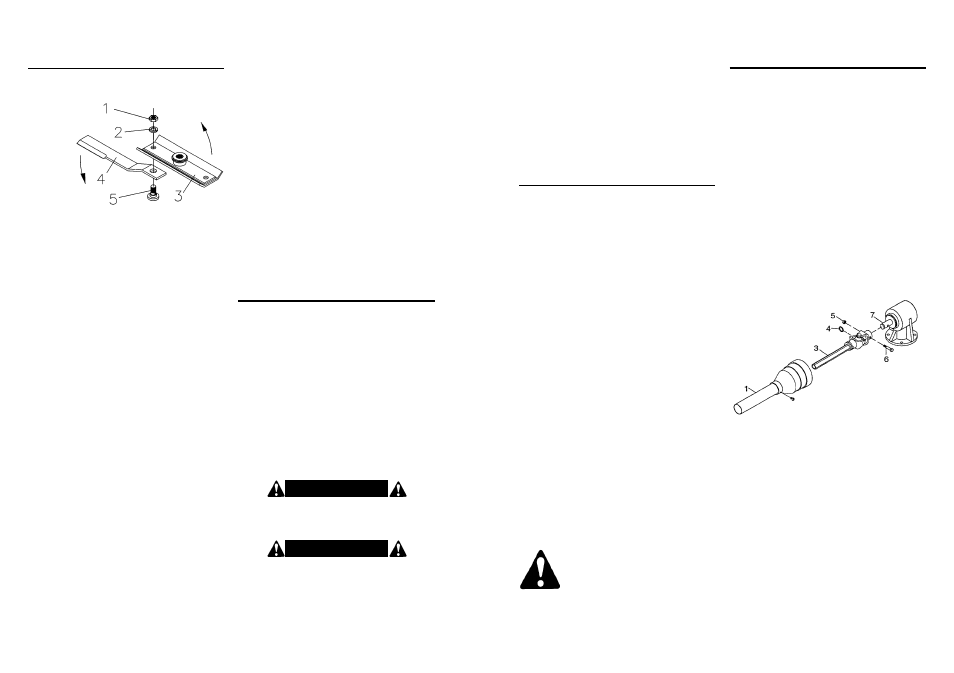

1. Drive shield

3. Input driveline shaft half

4. Retaining ring

5. Nut

6. Shearbolt grade 5 (

1

/

2

– 13 NC x 3” long)

7. Gearbox input shaft

Figure 2. Shear Bolt Driveline Installation

NOTE: A grade 5 bolt must be used for the shear bolt

to provide gearbox protection.

Align the holes in the driveline yoke and gearbox input

shaft and install and tighten shear bolt (6) and nut (5).

Install rear drive shield to driveline.

Lubricate rear driveline half and install front driveline

half.

SAFETY . . .

YOU CAN LIVE WITH IT!

NOTE: Front chain guards are required on this mower

when it is to be operated along roadsides or where

people, livestock, or property is present.

Even when chain guarding is used, it is recommended

to stop operation if people are present within 100 feet of

the mower.

ALWAYS USE CAUTION!

O W N E R S E RVICE

(continued)

B L A D E S E RV I C I N G

BLADE REMOVAL

(Figure 8)

1. Jam nut

2. Lockwasher

3. Blade beam

4. Blade

5. Blade bolt

Figure 8. Blade Installation

S H E A R B O LT R E P L A C E M E N T

Remove driveline shield bell. (Refer to page 19 for

instructions.)

Make sure the input shaft of the gearbox is greased.

This reduces the chance of the PTO shaft yoke from

galling to the input gearbox shaft if the shear bolt should

break.

Rotate driveline to align holes in yoke and shaft. Install

shear bolt and secure with locknut. Replace driveline

shield bell.

Disconnect driveline from tractor PTO.

It is necessary to gain access to bottom side of mower

for blade removal. Raise mower and block securely.

Align crossbar (3) with blade access hole in the mower

deck. Remove nut (1) and lockwasher (2) then carefully

drive bolt (5) out of crossbar.

Insert blade bolt (5) through blade, align key on blade

bolt with keyway in blade beam and push blade bolt

through blade beam. Insert lockwasher (2) and nut (1)

through blade access hole in the mower deck, install on

bolt (5) and tighten to 350 lbs.-ft.

Repeat for opposite blade.

Sharpen both blades at the same time to maintain bal-

ance. Follow original sharpening pattern. Do not sharpen

blade to a razor edge, but leave at least a

1

/

16

” blunt edge.

Do not sharpen back side of blade.

Rotate blade beam (3) and repeat for opposite blade.

Always replace or sharpen both blades at the same

time.

Inspect blade bolt (5) for nicks or gouges; replace if any

are found. Insert bolt through blade. Blade should swivel

on bolt. Determine cause if it does not and correct.

Align blade beam (3) with blade access hole in the

mower frame. Apply a liberal coating of Never Seez

®

or

equivalent to blade bolt and blade beam hole. Make sure

blade is offset away from mower.

Never Seez is a registered trademark of the

Never Seez Corporation.

W A R N I N G !

FAILURE TO USE CORRECT SIZE SHEAR BOLT

MAY CAUSE PERSONAL INJURY OR DEATH.

W A R N I N G !

FAILURE TO INSTALL RETAINING CLIP WILL

ALLOW DRIVELINE TO SWING FREELY IF BOLT IS

SHEARED CAUSING POSSIBLE INJURY OR DEATH.

IMPORTANT

If blade bolt (5) is seized in blade beam and extreme

force is required to remove it, support blade beam

from below to prevent gearbox damage.

IMPORTANT

When sharpening blades, grind each blade the

same amount to maintain balance. Replace blades in

pairs. Unbalanced blades will cause excessive vibra-

tion which can damage gearbox bearings. Vibration

may also cause structural cracks to mower.

IMPORTANT

Always use approved

1

/

2

” NC x 3” grade 5 shear bolt

as a replacement part. Using a hardened bolt or

shear pin may result in damage to driveline or

gearbox.

IMPORTANT

Blade beam rotation is counter-clockwise when

looking down on mower. Be sure to install blade cut-

ting edge to lead in counter-clockwise rotation.

BLADE SHARPENING