Farm Star MDM70-72C 6 User Manual

Page 27

17

26

T R A C T O R R E Q U I R E M E N T S

A N D P R E PA R AT I O N

The models MDM 70-60, MDM 70-60C, MDM 70-72

and MDM 70-72C Medium Duty Mowers require a

Category I 3-pt. hitch tractor of at least 25 horsepower for

5’ mowers and 35 horsepower for 6’ mowers and

equipped with a 540 rpm PTO (power takeoff) in good

working condition.

It is recommended that only tractors with wide front

axles be used with this cutter. Tricycle front wheel

arrangements are inherently unstable and tractor

roll-over accidents are more likely to occur.

The tractor also needs lift arm stabilizer bars or sway

blocks to control side movement of the cutter.

Check the tractor’s 3-pt. hydraulic lift system. Refer to

your tractor operator’s manual or dealer for any adjust-

ments necessary to put the hydraulic system in good

working order. (I&T shop manuals will list most specifi-

cations and adjustment instructions - available from most

farm equipment dealers.)

Be sure tires and rims are in good condition. Inflate

tires to the proper recommended air pressure.

All tractors that are not equipped with a “live” power

takeoff (PTO) need to be equipped with an over-running

PTO clutch.

Check the tractor master shield over the PTO stub

shaft. Make sure it is in good condition and fastened

securely to the tractor. Purchase a new shield if old

shield is damaged or missing. (You may have to use a

tractor salvage yard for replacement parts on older

tractors.)

It is recommended that a ROPS (Roll-Over Protection

Structure) and a seat belt be installed on all tractors.

Contact your local dealer for a ROPS for your tractor.

C A U T I O N !

Be sure your tractor is in good condition. Read all

the safety precautions and make sure all tractor

operators are familiar with the safety rules of

operation.

Figure 1. Tractor Stability

W A R N I N G !

When using the unit, a minimum 20% of tractor and

equipment weight must be on tractor front wheels.

Without this weight, tractor could tip up, causing

possible loss of control and possible personal injury

or death. The weight may be attained with a front

end loader, front wheel weights, ballast in tires or

front tractor weights. When attaining a minimum

20% of tractor and equipment weight on the front

wheels, you must not exceed the ROPS weight

certification. Weigh the tractor and equipment. DO

NOT GUESS OR ESTIMATE!

W A R N I N G !

A heavy load can cause instability in driving a

tractor. Make sure the front of the tractor is properly

counterbalanced with weights. Always drive slowly -

especially around turns. An unstable tractor could

steer badly and possibly tip over, causing injury or

death.

D A N G E R !

FOR AGRICULTURAL USE ONLY!

When this equipment is operated in populated

areas or other areas where thrown objects could

injure persons or property, full chain or rubber

shielding (which is designed to reduce the possibili-

ty of thrown objects) must be installed. If this

machine is not equipped with full chain or rubber

shielding, operation must be stopped when anyone

comes within several hundred feet.

I N S T R U C T I O N S

The operator is responsible for the safe operation of this

mower. The operator must be properly trained. Operators

should be familiar with the mower and tractor and all

safety practices before starting operation. Read the

safety rules and safety signs on pages 4-16.

This medium duty mower is designed for grass and

weed mowing, stalk shredding, and cutting brush up to 2

inch diameter.

Recommended mowing speed for most conditions is

from two to five mph.

O W N E R S E RVICE

(continued)

R E PAIR OF OPTIONAL

C H A I N S H I E L D I N G

Inspect chain shielding each day of operation and

replace any broken or missing chains as required.

S L I P C L U T C H A D J U S T M E N T

The slip clutch is designed to slip, protecting the gear-

box and driveline, should the cutter strike an obstruction.

A new slip clutch, or one that has been in storage over

the winter, may seize. Before operating, make sure it will

slip by performing this operation:

Make sure tractor engine is turned off and key is

removed.

Remove driveline from tractor PTO.

The slip clutch is factory preset to the correct torque for

protecting implement and tractor.

Loosen the eight bolts to remove all tension from

springs (until spring can be turned with fingers).

Hold clutch hub solid and turn shaft to make sure clutch

slips.

If clutch does not slip freely, disassemble and clean the

faces of clutch plate, yoke and plate, and clutch hub.

Reassemble clutch.

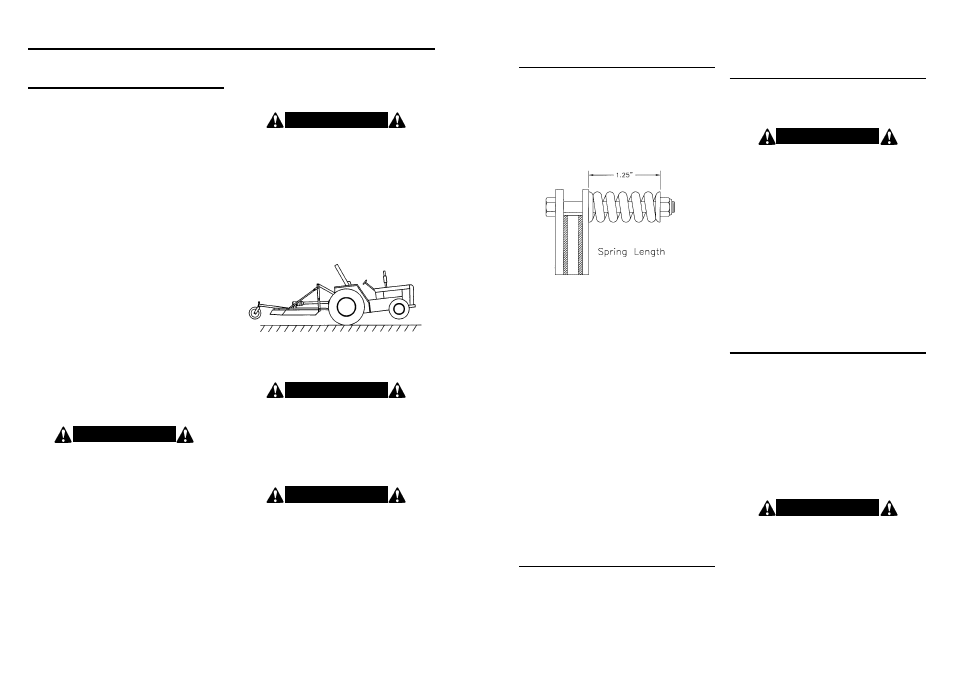

Tighten each of the eight bolts evenly until the springs

are compressed to 1.25” as shown in figure 9. If neces-

sary, adjust nut on any spring that is unequal. Adjust all

eight spring retaining nuts 1/3 of a turn (2 flats on a nut)

and check clutch slippage. If further adjustment is nec-

essary, do so in 1/3 increments. Adjust only to provide

sufficient torque to prevent slippage under normal condi-

tions. Occasional slippage is normal for drivetrain pro-

tection. If satisfactory results cannot be obtained, consult

your dealer.

If a clutch continues to slip when the springs are com-

pressed to 1.25”, check friction disc for excessive wear.

Discs are 1/8” when new. Replace discs after 1/16” wear.

Minimum disc thickness is 1/16”.

B L A D E B E A M & G E A R B O X

R E M O VA L

A. Raise mower using tractor 3-point lift. Turn off tractor

engine.

B. BLOCK MOWER SECURELY INTO POSITION.

B L A D E B E A M & G E A R B O X

I N S TA L L AT I O N

A. Raise mower using tractor 3-point lift. Turn off tractor

engine.

B. BLOCK MOWER SECURELY INTO POSITION.

C. Attach gearbox to mower deck using bolts and nuts.

D. Install blade holder onto gearbox securing with

castellated nut and flat washer. Torque nut to 350

ft./lbs. Wear heavy work gloves to protect hands from

sharp edges.

E. Install cotter pin to retain nut. It may be necessary to

slightly loosen nut to install cotter pin.

F. Slide driveline yoke onto gearbox input shaft. Install

retaining clip and shear bolt. (Shearbolt Models)

C. Remove cotter pin and blade holder retaining nut.

Wear heavy work gloves to protect hands from sharp

edges.

D. Grasp blade holder and pull off shaft. If necessary,

align blade bar with access hole in top of deck and

drive off with hammer and pipe. Care should be taken

not to damage threads on blade bolt.

E. Press all three tabs and slide yoke shield back.

F. Remove shear bolt and retaining clip. Slide yoke off

gearbox input shaft.

G. Remove nuts securing gearbox to deck. Remove

gearbox.

G. Lock driveline yoke shield securely into place.

H. Fill gearbox with oil to proper level.

W A R N I N G !

DO NOT GET UNDER MOWER UNLESS IT IS

SECURELY BLOCKED IN POSITION. ACCIDENTAL

FALL COULD CAUSE SERIOUS INJURY OR DEATH.

W A R N I N G !

ON SHEARBOLT MODELS, FAILURE TO INSTALL

RETAINING CLIP WILL ALLOW DRIVELINE TO COME

OFF GEARBOX AND SWING FREELY IF BOLT IS

SHEARED CAUSING POSSIBLE INJURY OR DEATH.

Figure 9.