Fairbanks 12-1492 - 12-1496 A.A.R. Combination Railroad Track/MTS User Manual

Page 45

04/12

45

50538 Rev. 7

Weld additional support between crossmembers as needed

50538-36 Rev. 2

7: Additional supports are required (between the crossmembers and outriggers) to prevent

the corrugation from collapsing when the redi-mix concrete is poured and floated. This sup-

port can be provided by welding flat steel plate or reinforcement rod as shown.

8: Install the manholes exactly as noted in the certified prints. Ensure they are placed in

their correct positions on the corrugation, and are supported properly. Fill a large plastic bag

with loose dry dirt or sand and place it in each manhole ring (this will keep the redi-mix con-

crete out of the ring). Place the covers onto both manhole assemblies.

50538-37 Rev. 2

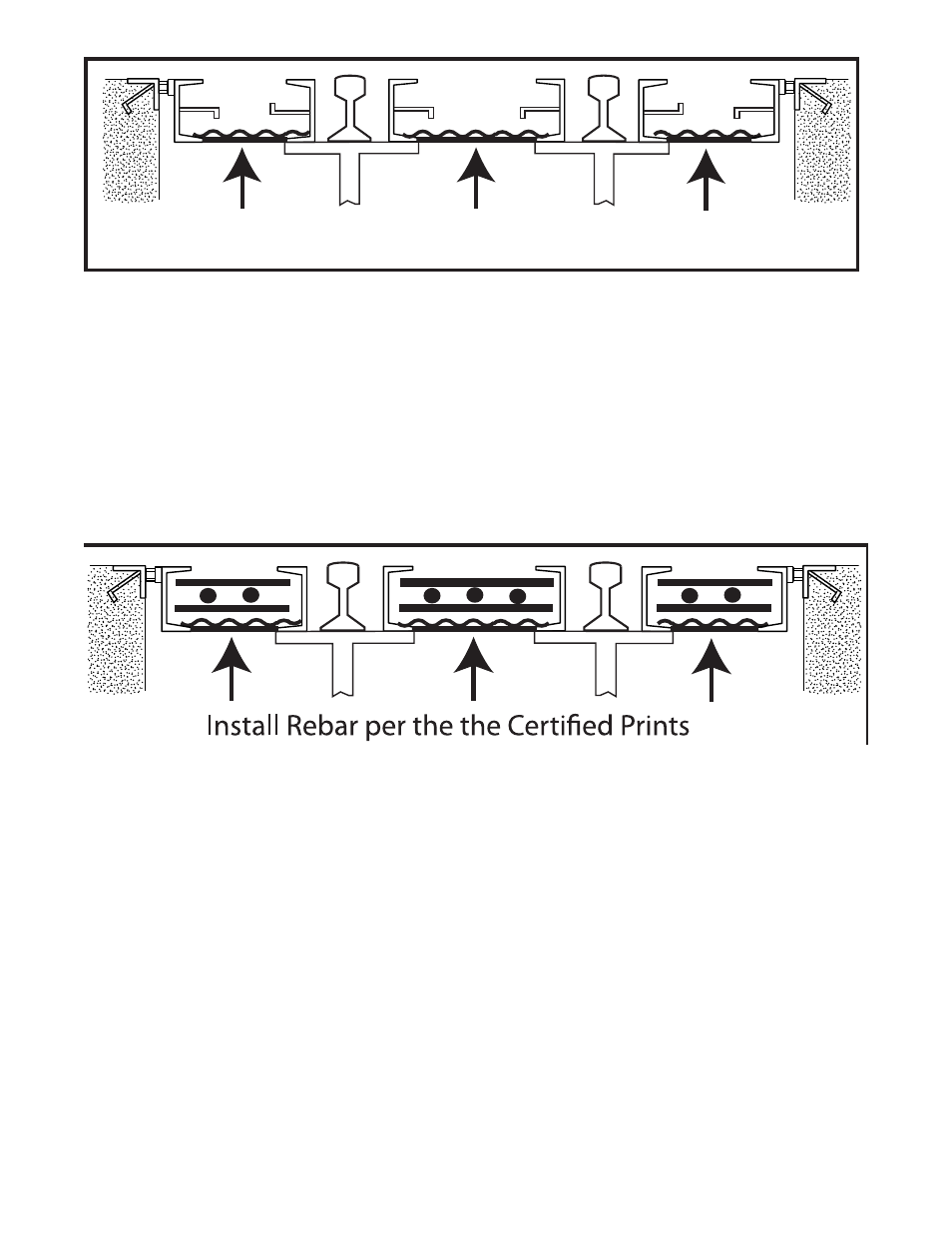

9: Install, block, and tie the rebar per the certified prints. Ensure the rebar is lifted from the

corrugation to provide the specified concrete cover, per the certified prints.

10: Pour, float, edge, and broom finish the concrete mix.

All concrete workmanship shall be performed in accordance with the best practice as

described by the American Concrete Institute.

Allow concrete to cure thoroughly. Do not use, or subject the deck to any traffic until the con-

crete has attained its ultimate compressive strength of 3000 psi after 28 days.

NOTE: The installation and finishing of poured concrete is best left to trained, experienced,

and well equipped personnel.