Weld, Rail pocket rail pocket, Corrugated sheet metal deck forming – Fairbanks 12-1492 - 12-1496 A.A.R. Combination Railroad Track/MTS User Manual

Page 44

04/12

44

50538 Rev. 7

Weld

50538-34 Rev. 2

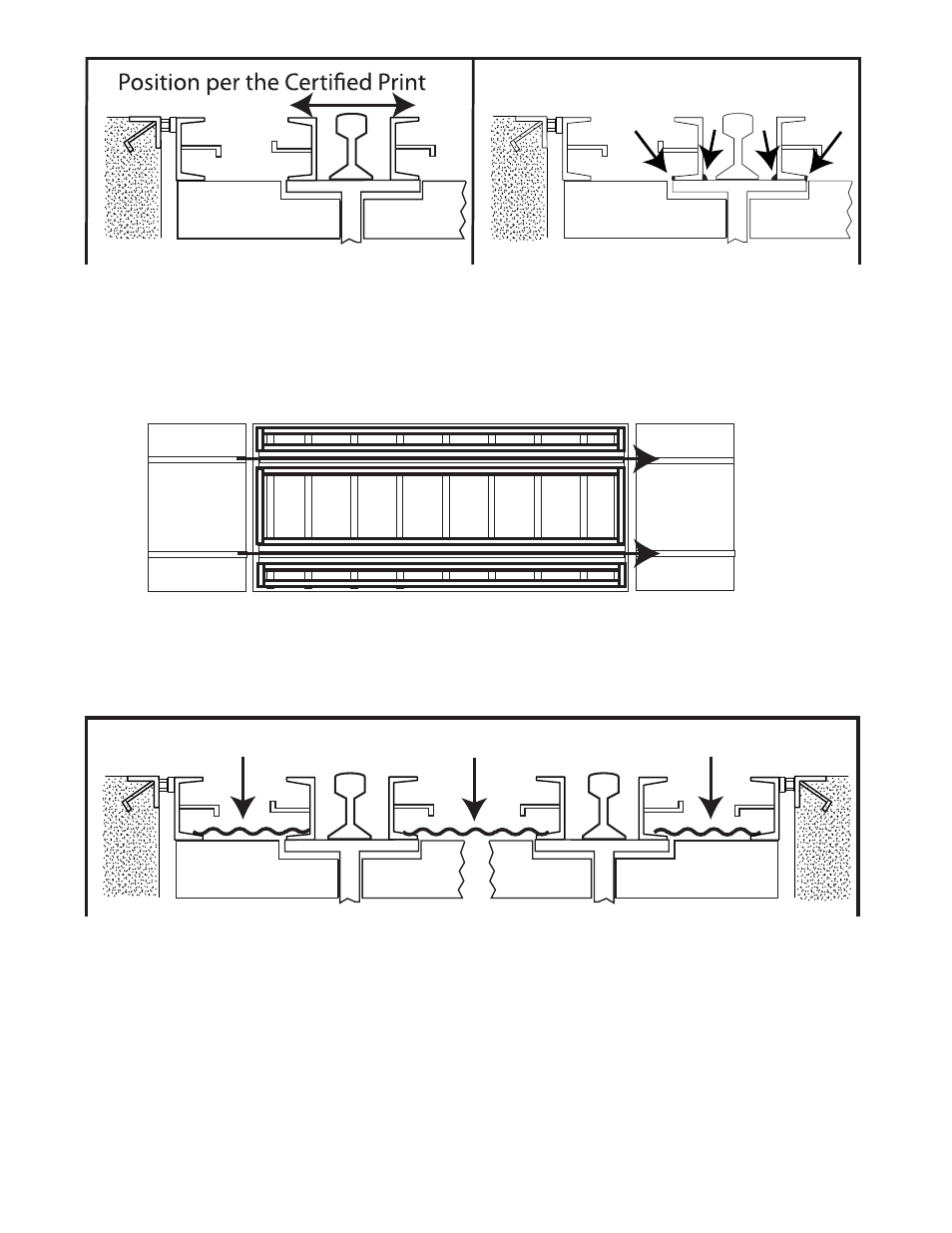

4: Layout the deck coping on the main beams beside each rail as shown. Position the deck

coping to provide rail clearances per the certified prints. Ensure they are straight. Clamp and

weld the deck coping as shown. Welds should be one (1) inch long, and at sixteen (16) inch

intervals more if required.

Top View of Scale

Rail

Rail

50538-33

5: At the twelve (12) corner junctures of the deck coping, and at all other points, ensure there

are no gaps or openings through which redi-mix concrete can leak. Cut and weld steel plate

to cover any gaps or openings as necessary.

Corrugated Sheet Metal Deck Forming

50538-35 Rev. 2

6: Corrugated steel sheets are used for deck forming, and can be purchased in a variety of

different configurations, thickness, and dimensions. It is recommended to use steel galva-

nized sheets, 22 to 24 gauge, and 9/16 inches high. Cut the corrugation to fit tightly at the

bottom flanges of the deck coping, and overlap the adjoining sheets by three (3) feet.

Ensure all corrugation is resting on the lower flanges of the deck coping. If required, fasten

the corrugation where needed to secure it into position.