Level – Fairbanks 12-1492 - 12-1496 A.A.R. Combination Railroad Track/MTS User Manual

Page 33

04/12

33

50538 Rev. 7

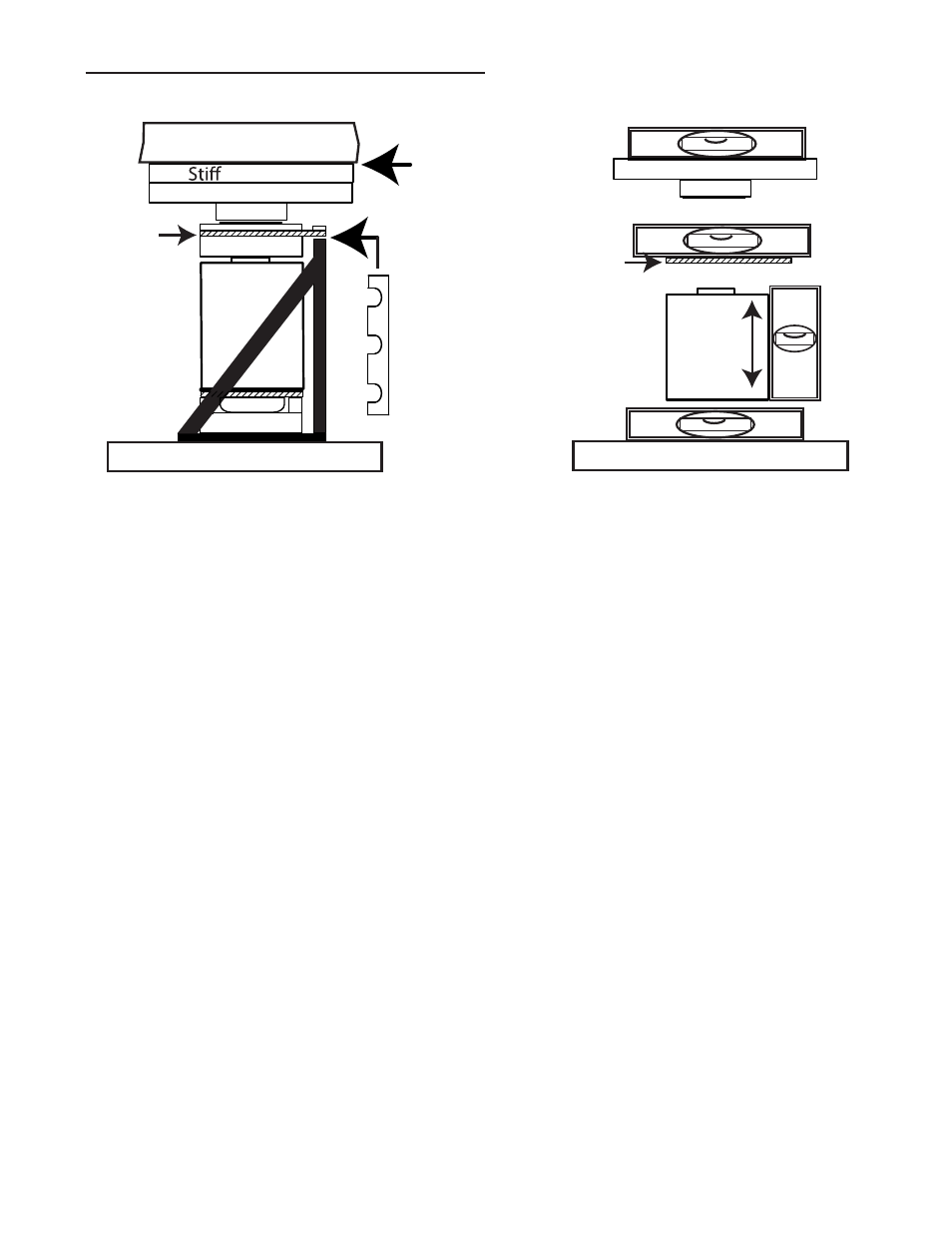

2-P: Leveling Load Cell Flexure Assemblies:

ener Plate

Top Bearing Plate

Upper

Flexure

Base Plate

LEVEL

Main Beam

LEVEL

Upper

Flexure

Base Plate

Top Bearing Plate

LEVEL

LEVEL

Load

Cell

Load

Cell

A

B

50538-19A

1: Starting at one end section, lift the main beam slightly from one load cell at a time and

loosen the three screws that secure the flexure to the support assembly block, and note any

space between the flexure and the block. Use a precision level across the flexure and add or

remove shims between the flexure and the block to get best possible level on the flexure and

insure there are no spaces or gaps (see "A" above). Tighten the three screws to torque spec-

ifications.

2: Check that the top bearing plate assembly is level and at right angles to the main beam

web. If adjustment is necessary, install shims only between the main beam's lower flange

and the stiffener plate ( see "B" above). Shims must extend the full length of the bearing

surface.

3: Check that the load cell is vertical and that the top bearing plate is centered on the flexure

wear plate. Adjust if necessary. Ensure the base plates, load cell, upper flexure plate, and

top bearing plate assembly are level to within 1/64” per foot.

4: Continue for each load cell flexure assembly.

5: Providing a suitable power supply to connect to the loadcells, measure and record the

mV/V output from each load cell in the scale. The resulting readings will indicate the current

weight distribution of the scale's deadload among the eight (8) points of support. The outputs

will be greater for number's 3, 4, 5, and 6 because there is physically more deadload weight

upon them.