6: part ii, 3 sample system – Teledyne 3010TB - Split architecture trace oxygen analyzer User Manual

Page 68

2-6: Part II

2 Operational Theory

Model 3010T

Teledyne Analytical Instruments

2.3

Sample System

The sample system delivers gases to the Micro-Fuel Cell sensor from

the Analysis Unit Gas Control Panel inlets. Depending on the mode of

operation either sample or calibration gas is delivered.

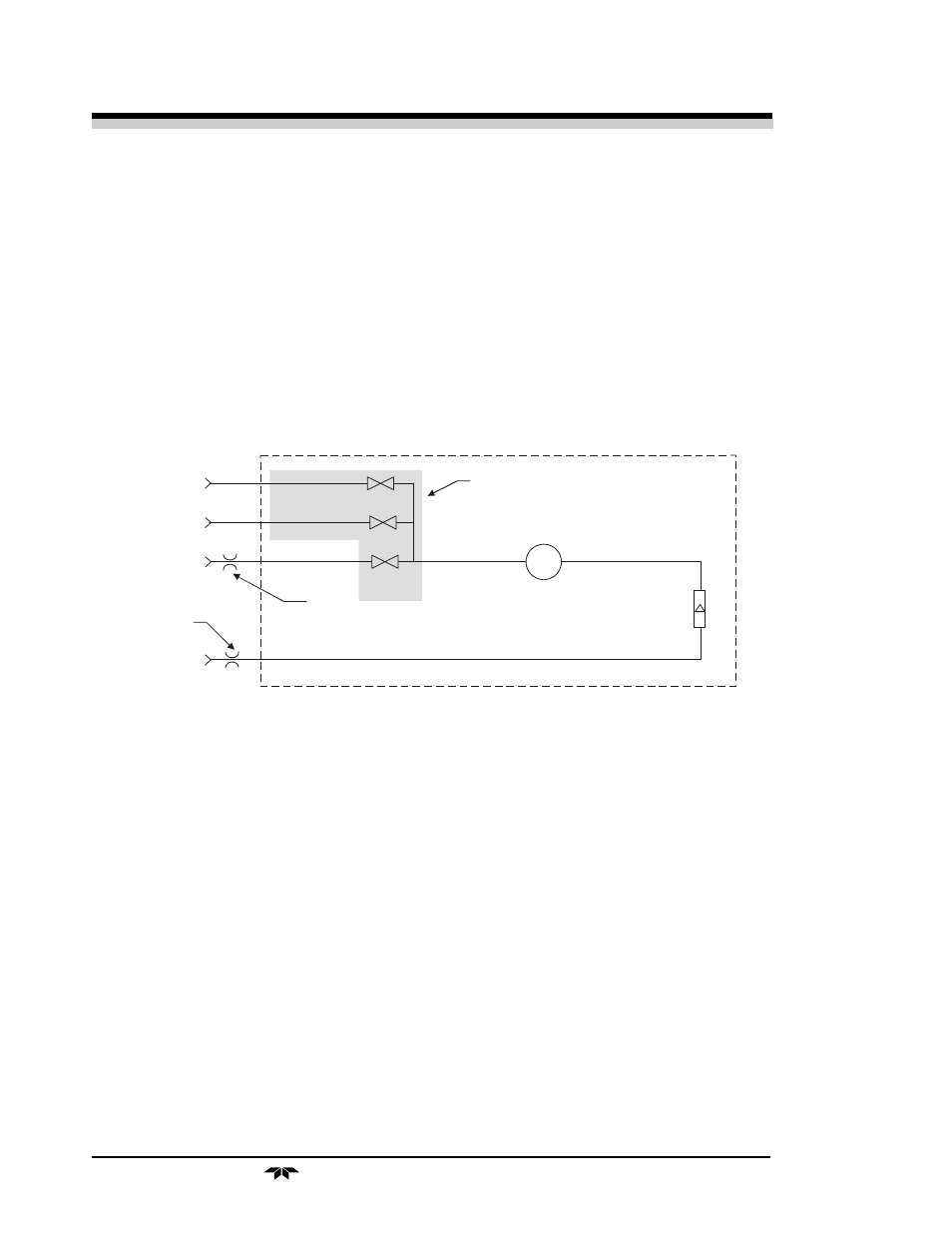

Figure 2-4 is a typical flow diagram for the sampling system. The flame

arrestors and valves (shaded) are optional.

When the –C option is ordered, the valves are installed inside the 3010

enclosure and are regulated by the remote Control Unit electronics.

Figure 2-4: Flow Diagram

The Model 3010T sample system is designed and built to ensure that

the oxygen concentration of the gas is not altered as it travels through the

sample system. The sample encounters almost no dead space. This mini-

mizes residual gas pockets that can interfere with trace analysis.

The metal restrictor upstream from the cell helps manage the flow

through the system (1 SLPM at 20 psig for nitrogen). It is corrosion and

blockage resistant.

The sample or calibration gas flowing through the system is monitored

by a flowmeter downstream from the cell. The sample system for the stan-

dard instruments incorporates

1/4

inch tube fittings for sample inlet and outlet

connections on the Gas Control Panel. For metric system installations, 6 mm

adapters are supplied.

For -Vacuum Service, the restrictor is located downstream of the

flowmeter. The restrictor is installed in the exhaust port on the gas panel.

In vacuum service the

restrictor should be

placed here.

Sample In

Span In

Zero In

Flowmeter

Exhaust Out

Solenoid

Valves

Restrictor

Cell

In normal service the

restrictor should be

placed here.

Components in the shaded area are in

the -C option (internal control valves)

only and are not shown in the piping

diagram above.