SPP Pumps Auto Prime Medium Head Open Set ACE80-100 Workshop Manual User Manual

Page 9

Workshop Manual for

ACE80/100 Diesel Driven Centrifugal Pumps

Manual No/Rev

W72-020E / 1

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 9 of 21

This manual is a preliminary issue

for information only,

pending formal issue of

the complete manual.

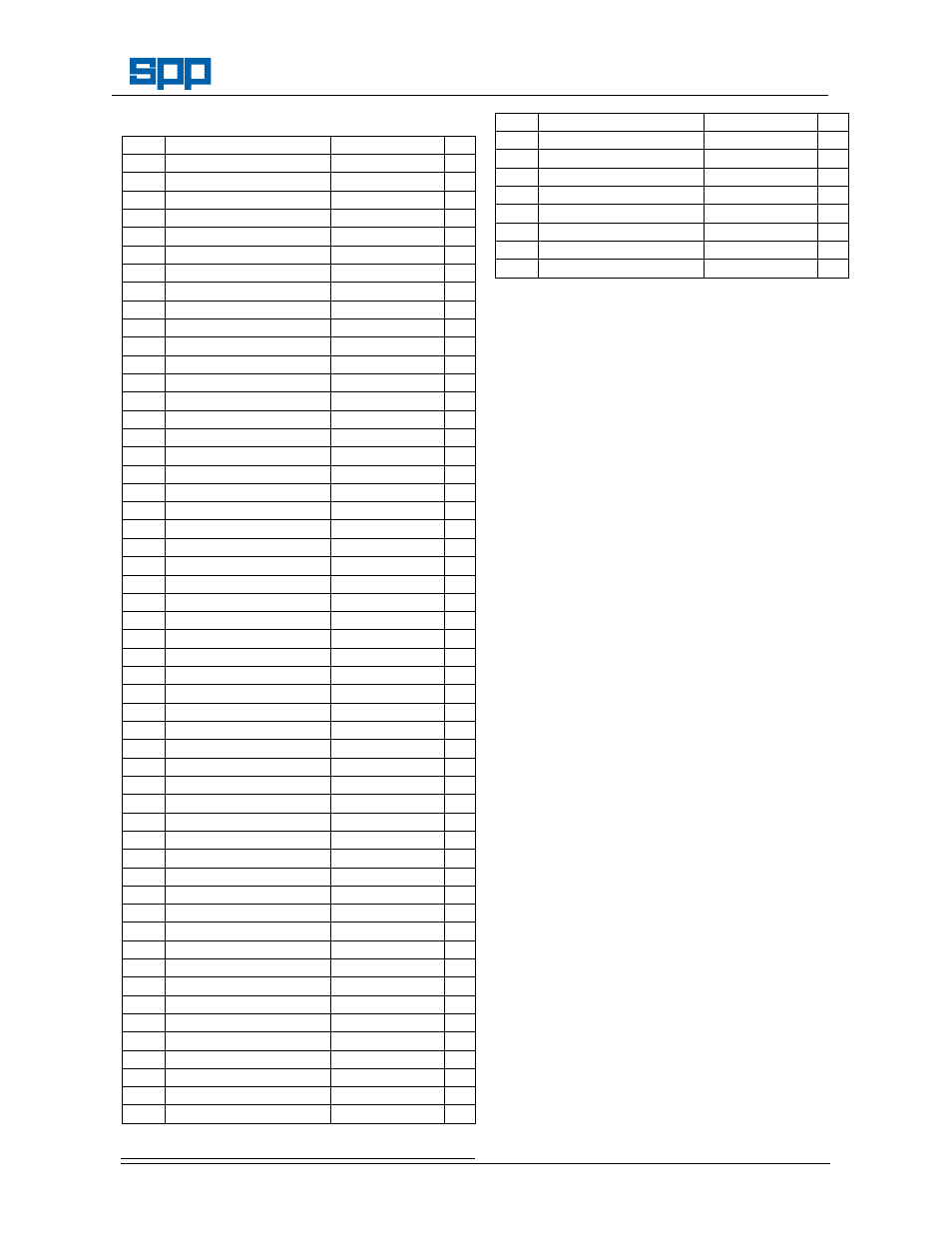

6.2 Pump End Parts List:

Item Description

Part No

Qty

10 Engine:Hatz 1d90

*E41853B001*

1

11 Stud:M10x60

SY9509097

8

12 Washer:Spring M10

21174-306-927-6

8

13 Nut:Hex Full M10

21882-673-958-3

8

14 Stubshaft

22319

1

15 Capscrew:M8x25

21835-136-977-1

4

16 Washer:Spring M8

21174-305-927-9

4

20 Adaptor:Engine/Pump

22318

1

21 Stud:M10x30

SY9509089

8

22 Washer:Spring M10

21174-306-927-6

8

23 Nut:Hex Full M10

21882-673-958-3

8

24 'O'RING 199.5ID X 3.0

22384.017

1

30 Mech Seal 45

13763

1

31 Washer:Mech Seal

13938

1

32 Circlip: Ext 45

13772

1

40 Wearplate:Back Hsg

22317

1

41 O'RING 219.5ID X 3.0

22385.017

1

50 Mech Seal 45

13763

1

51 Impeller

22321

1

52 Shim:Impeller 1mm

22323

1

53 Shim:Impeller 0.5mm

22324

1

60 Volute

22655

1

61 Stud:M10x30

SY9509089

6

62 Stud:M10x25

SY9509087

6

63 Washer:Spring M10

21174-306-927-6

12

64 Nut:Hex Full M10

21882-673-958-3

12

70 Tee Piece

22320

1

71 Gasket

SY5004439

1

72 Gasket

SY5004432

1

73 Wear Plate

SY3874016

1

74 Stud:M10x30

SY9509089

4

75 Washer:Spring M10

21174-306-927-6

4

76 Nut:Hex Full M10

21882-673-958-3

4

77 Screw:Hex Hd M12x40

21863-222-959-4

2

78 Nut:Hex Full M12

21882-673-958-3

2

80 Valve:Non-Return

22325

1

81 Ball:Nrv (Green)

8075

1

82 Seat:Nrv

SY3874014

1

83 Bolt:Hex Hd M12x230

22326

4

90 Assy:Priming Tank

SY3802500

1

91 Gasket

SY5004373

1

92 Stud:M12x40

SY9509133

8

93 Washer:Spring M12

21174-307-927-3

8

94 Nut:Hex Full M12

21882-675-958-7

8

100

110 Adaptor:Male

15533

2

120 Valve:Ball 1/2" Bsp

22416

1

130 Hosetail

12149

1

140 Clip:Hose:18-25mm

5837

1

150 Hose

15446

600

160 Assy:Backprime Line

*E41853A007*

1

170 Adaptor:Male

22606

1

180 Valve:Non Return

SY3714105

1

Item Description

Part No

Qty

190 Dipstick

14373

1

200 'O'RING 24.5ID X 3.0

25154-024-716-1

1

210 Elbow:Male Stud

25346-221-000-7

1

220 Clip:'P' Type

14150

1

230 Tube

17341-711-076-4

500

240 Adaptor:Male

22607

1

250 Plug:3/8" Bsp

25221-383-915-0

1

260 Plug:1/4" Bsp

25221-382-915-3

2

6.3 Pump End Assembly (See section 7.1)

1.1

Refer to the pump end section drawing in

section 7.1

1.2

Place engine (10) on a workbench that is

equipped with lifting equipment suitable to

lift the pump and engine assembly complete.

1.2

Fit eight M10 x 60 studs (11) onto the

engine flywheel casing.

1.3

Fit the stubshaft (14) onto the flywheel on

the engine with four M8 x 25 capscrews (15)

and spring washers (16).

1.4

Place the engine/pump adapter (20) over

the stubshaft and secure using the studs on

the engine with nuts (13) and spring

washers (12).

1.5

Fit eight M10 x 30 studs (21) into adapter.

1.6

Place the 199.5ID ‘O’ ring (24) over the

adapter.

1.7

Fit the secondary mechanical seal stationary

element (30) over the shaft and press it into

the adapter plate ensuring not to damage

the face.

1.8

Fit the rotating element of the mechanical

seal (30) and push it onto the shaft until the

circlip groove is exposed behind the seal.

1.9

Fit the circlip washer (31) followed by the

circlip (32) and ensure the mechanical seal

is securely in place and pulled back against

the circlip.

1.10 Fit the back wearplate (40) over the shaft

and secure using the studs in the adapter

plate with nuts (23) and spring washers (22).

1.11 Fit the remaining ‘O’ ring (41).

1.12 Fit the stationary seat of the primary

mechanical seal (50) over the shaft and

press into the wearplate.

1.13 Fit the rotational part of the mechanical seal

so that it touches the stationary seal face.

1.14 Screw on the impeller (51) (clockwise) and

check the back vane to wear plate clearance

is 0.5-1mm. If it does not fall within this

range, add shims (52 & 53) to give the

required clearance.