Maintenance, Troubleshooting gas fired boilers – Fulton Classic ICX or FB-F Vertical Tubeless Boilers (Hot Water), Gas_Oil Fired User Manual

Page 41

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

SECTION 4

ICW-IOM-2014-0410

MAINTENANCE

4-11

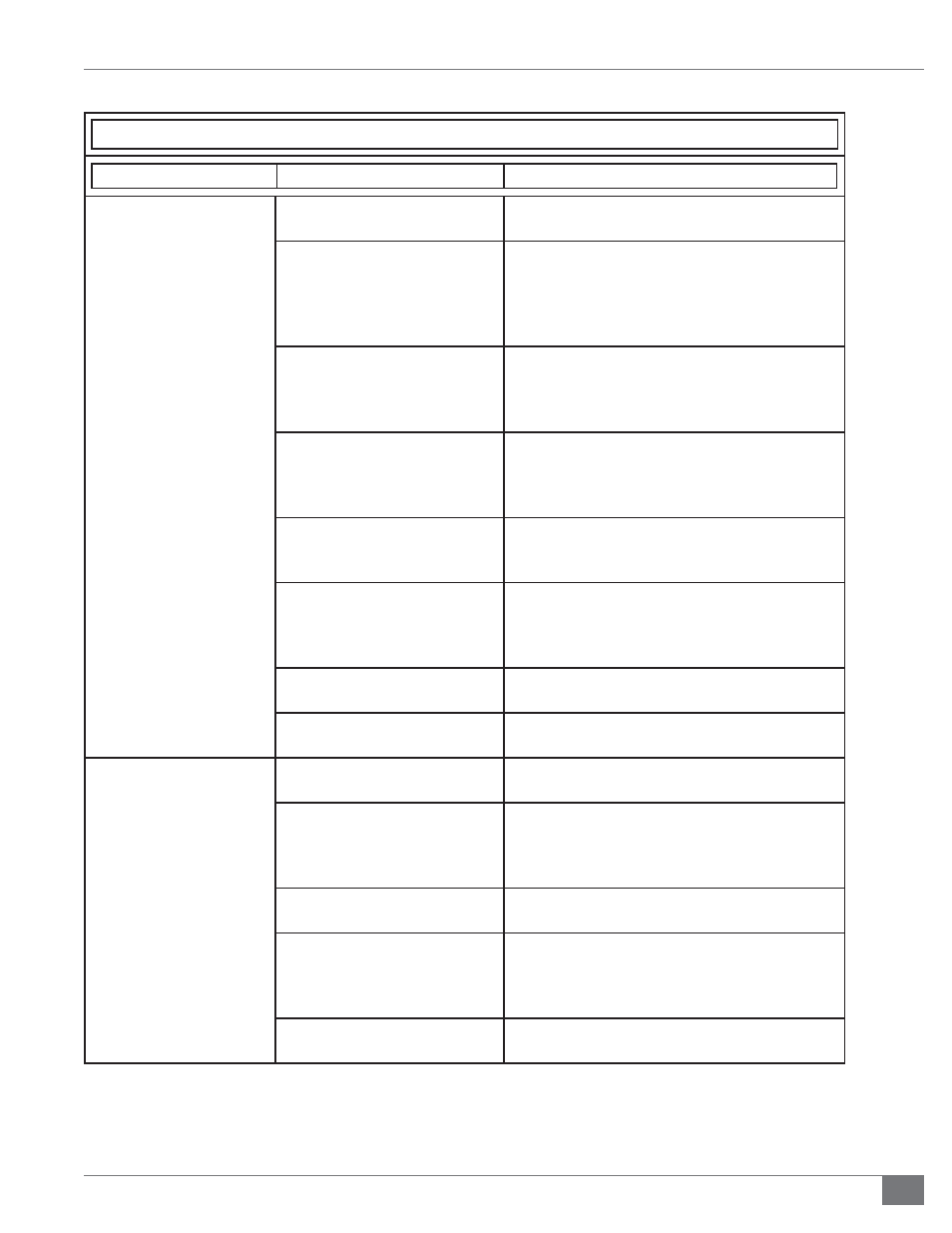

Troubleshooting Gas Fired Boilers

Problem

Potential Cause

Potential Remedy

Poor Combustion

Refractories

Check refractories to see if they are cracked or

broken in pieces. Replace as necessary.

Not Enough Air/Build-Up on Fan

Wheel (Rich; Burner Hums)

Check CO2/O2 levels. If rich, disassemble fi lter

housing and gas train. Look inside inlet to the

fan. If there is build-up on the fan blades, clean

fan. Recheck the CO2/O2 and adjust gas valve as

necessary for all combustion points.

Fuel Valve Adjusted Too High

(Rich; Burner Hums)

Check CO2/O2 levels. Check gas pressure at

outlet of valve. If the pressure is too high, make

an adjustment at the valve. Be sure to check all

combustion points.

Too Much Air (Lean; Unstable

Flame)

Check fan discharge pressure. If too high,

adjust damper. Check CO2/O2 levels and adjust

gas valve as necessary. Be sure to check all

combustion points.

Gas Valve Adjusted Too Low

(Lean; Unstable Flame)

Check CO2 and O2 levels. Check pressure at outlet

of the valve. If too negative, adjust gas valve as

necessary.

Draft

Check draft with a gauge. Draft should be a -.02

in to -.04 in wc with burner off or -.04 in to -.06 in

when operating. May need to install a barometric

damper.

Dirty Flue

Check fl ue for carbon buildup or blockage. Clean

fl ue passages with brush.

Negative Room Pressure

Make sure no exhaust fans are running in the

boiler room.

Burner back fi res

Refractories

Check refractories to see if they are cracked or

broken in pieces. Replace as necessary.

Ignition Electrodes

Check electrodes for carbon buildup and clean if

necessary. Check for proper adjustment. Readjust

if necessary. Check for cracks in porcelain; if found

replace.

UV Scanner

Check for debris on fl ame scanner and clean as

needed. Check for proper location of detector.

Draft

Check draft with a gauge. Draft should be a -.02

in to -.04 in wc with burner off or -.04 in to -.06 in

when operating. May need to install a barometric

damper.

Negative Room Pressure

Make sure no exhaust fans are running in the

boiler room.