Installation – Fulton Classic ICX or FB-F Vertical Tubeless Boilers (Hot Water), Gas_Oil Fired User Manual

Page 12

© The Fulton Companies 2014

INSTALLATION

ICW-IOM-2014-0410

SECTION 2

2-6

3. See Table 3 for minimum make up air openings required

for each model.

TABLE 3- MINIMUM MAKE UP AIR OPENING REQUIREMENTS

Model

Fresh Air Opening FT2 (M2)

ICW 6

1 (.09)

ICW 10

1 (.09)

ICW 15

1.5 (.14)

ICW 20

4 (.37)

ICW 30

4 (.37)

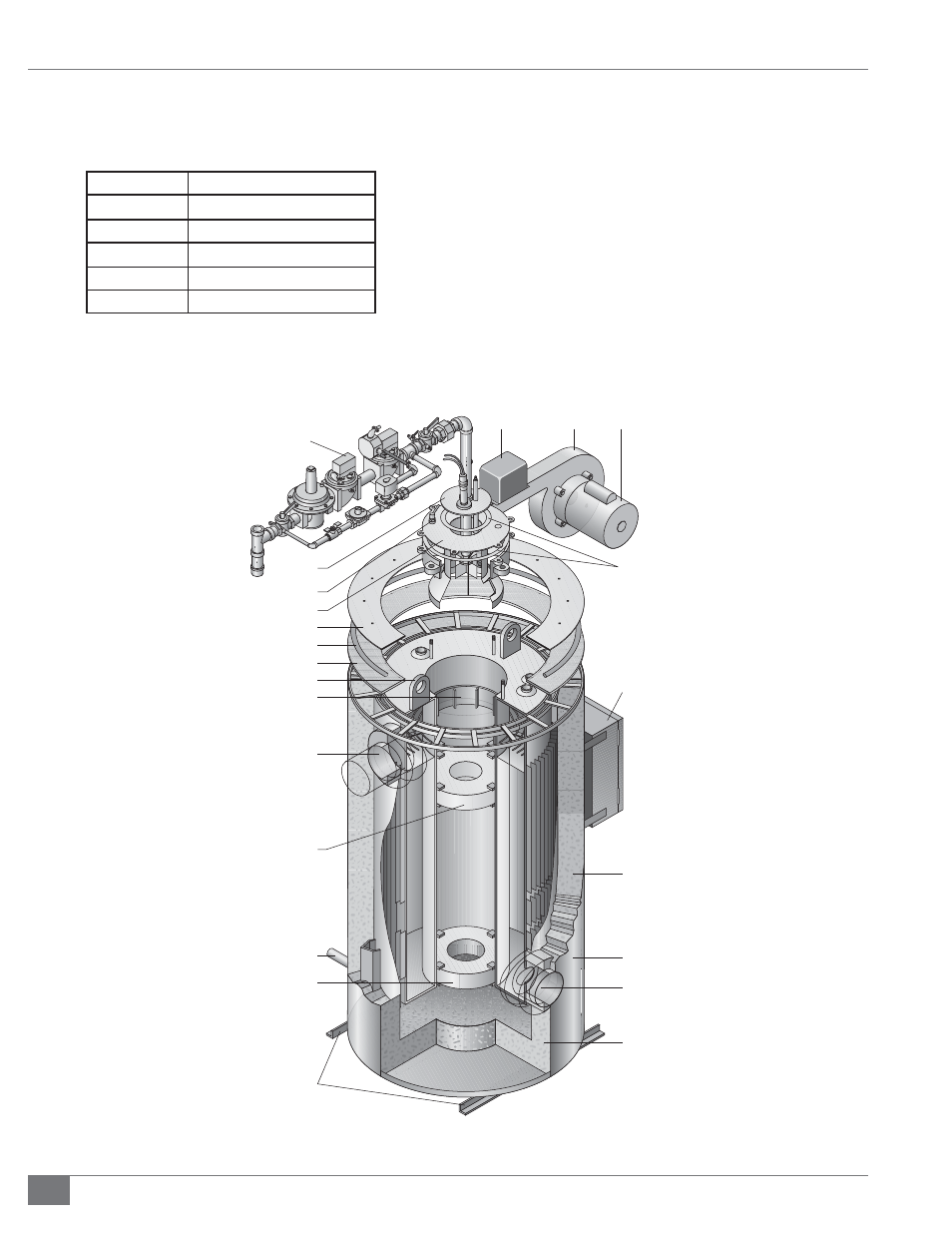

Transformer

Scroll

Gaskets

Burner Motor

Control Box

High Density

Insulation

Outside Jacket

Handhole

Boiler Runners

Flue Outlet

Lifting Hook(s)

Flue Blanket

Flue Rope Gasket

Flue Plate Cover

Top Plate Assembly

Gas Train Assembly

Secondary Air Damper

Burner Plate

Assembly

Stainless Steel Ring (oil only)

Bottom Refractory

Top Refractory

Castable

Refractory

Insulation

Water Return

4. If positive forced ventilation is adopted, ensure that

there will be no appreciable pressure variation in the

equipment room.

5. Avoid ventilation which creates a negative pressure

in the building as it will seriously aff ect combustion

and proper operation of the burner. Please note that

exhaust fans or similar equipment can create a down

draft in the chimney or starve the burner’s air supply.

Either case may result in poor combustion or nuisance

failures. A properly designed make-up air system in the

equipment room will preclude these possibilities and is

required to maintain proper combustion.

FIGURE 2 -COMPONENT VIEW OF THE ICW UNIT