Maintenance, Recommended semi-annual maintenance schedule – Fulton Classic ICX or FB-F Vertical Tubeless Boilers (Hot Water), Gas_Oil Fired User Manual

Page 33

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

SECTION 4

ICW-IOM-2014-0410

MAINTENANCE

4-3

!

WARNING

Crystalline silica may be present

in components of this equipment.

Exposure to crystalline silica may

pose signifi cant health hazards,

including but not limited to eye and

respiratory system damage. Per

the Centers for Disease Control and

Prevention (CDC) and Occupational

Safety and Health Administration

(OSHA), appropriate Personal

Protective Equipment must be worn

to minimize exposure to hazardous

substances. Refer to most current

guidelines off ered by the CDC and

OSHA for more information, including

Personal Protective Equipment

recommendations.

Never use open fl ame or other sources

of ignition to check for gas leaks.

4

CAUTION

All maintenance procedures should

be completed by trained personnel.

Appropriate training and instructions

are available from the Fulton Service

Department at (315) 298-5121 or your

local Fulton Thermal Representative.

In order to meet warranty conditions,

ensure all appropriate maintenance

activities are performed.

Use caution when using any cleaning

solutions. Refer to local regulations for

proper cleaning solution disposal.

If the gasket leaks while pressure is

being built up, tighten only enough to

stop leakage. Never tighten more than

necessary to prevent leakage. Excessive

tightening may shorten the life of the

gasket.

Recommended Semi-Annual Maintenance Schedule

The following steps should be carried out semi-annually:

1. Clean the gas burner assembly:

» Disconnect the gas head from the burner by disconnecting the

union. Withdraw the burner assembly and clean the ignition

electrode.

» Check that the settings of the gap, if applicable, and ignition

electrode are accurate.

» Reassemble the burner assembly and check the scanner setting.

» Check the combustion effi

ciency of the burner and adjust if

necessary.

2. Check electrical controls and motors for correct operation.

3. Check water pump for correct operation.

4. Shut

off the boiler completely and drain.

5. Replace hand hole gaskets as follows:

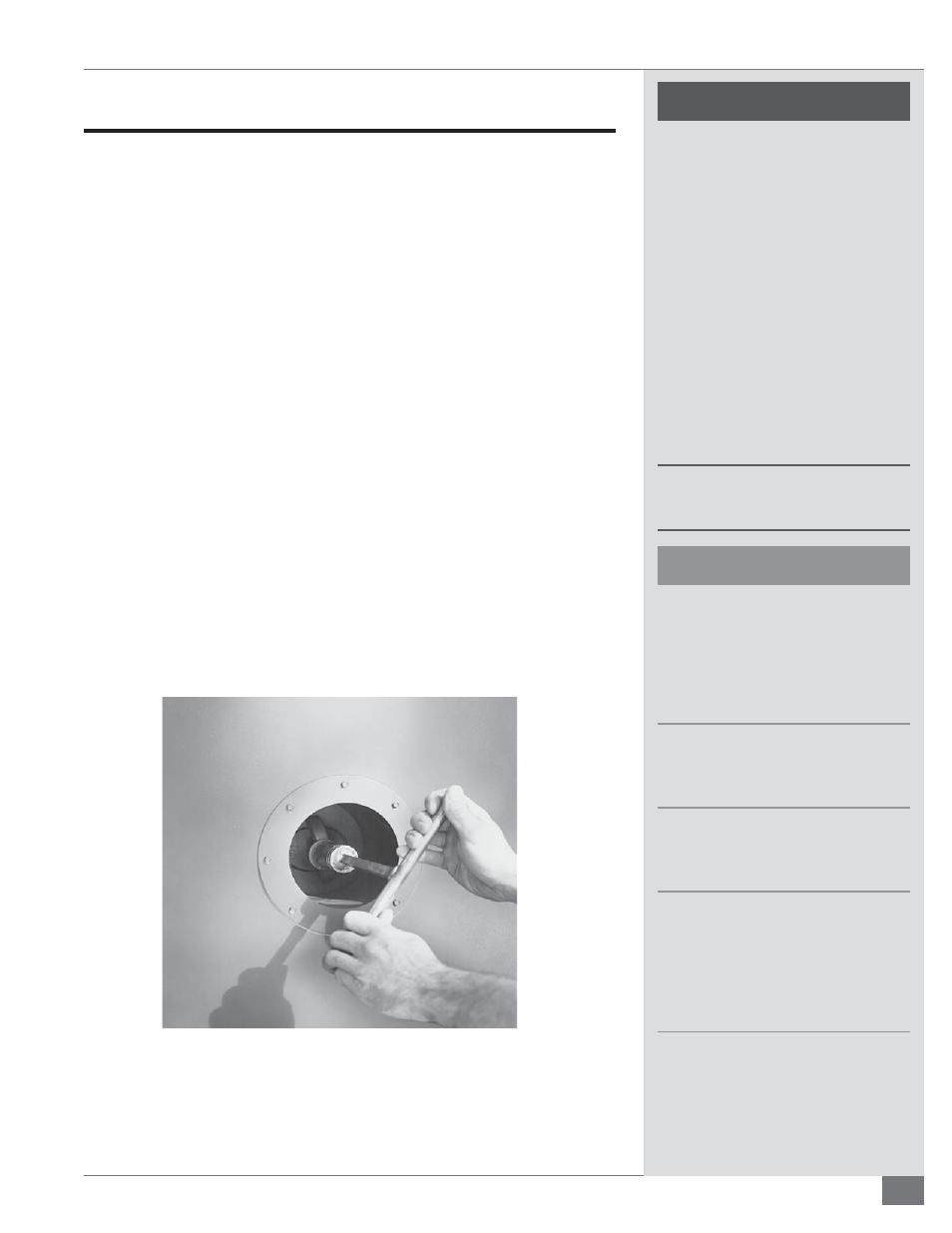

» Remove the hand hole assembly using a 1-1/4” tee handle

wrench or 1-1/4” 1/2” drive socket wrench. See Figure 5. Remove

the old gasket and thoroughly clean the surface on the boiler and

the plate.

FIGURE 5 - REMOVE ASSEMBLY WITH TEE HANDLE WRENCH