Installation, Stack and flue, Pressure gauges – Fulton Classic ICX or FB-F Vertical Tubeless Boilers (Hot Water), Gas_Oil Fired User Manual

Page 19

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

SECTION 2

ICW-IOM-2014-0410

INSTALLATION

2-13

!

WARNING

All information in this manual is for

reference and guidance purposes,

and does not substitute for required

professional training, conduct,

and strict adherence to applicable

jurisdictional/professional codes and

regulations.

Assure all electrical connections are

powered down prior to attempting

replacement or service of electrical

components or connections of the

equipment.

Cements for plastic pipe should

be kept away from all sources of

ignition. Proper ventilation should

be maintained to reduce the hazard

and to minimize breathing of cement

vapors.

No shutoff of any kind may be

placed between the safety relief

valve and the equipment, or in the

discharge pipe between such valve

and the atmosphere. Doing so may

cause accidental explosion from

overpressure.

Discharge from safety relief valve

must be confi gured so that there

is no danger of scalding personnel

or causing equipment damage.

Provisions must be made to properly

drain safety relief valve discharge

piping.

For reasons of safety, the hot exhaust

gas duct and chimney must be

insulated or shielded within the

locality of the heater in compliance

with local codes and regulations.

4

CAUTION

The stack arrangement and draft

conditions should be in accordance

with the information in this manual for

proper performance of the equipment.

Pressure Gauges

The range in which readings are expected to fall should comprise mid-scale

on the pressure gauge chosen. Pressure gauges must be able to withstand

overpressure equal to the rating of the safety relief valves, normally 100 psig.

NOTE:

The Water temperature pressure gauge should not be altered in any way.

Stack and Flue

An appropriately sized stack should be connected to the fl ue gas outlet at the

boiler. The proper fl ue size and draft control is most important for proper burner

operation. See Table 4.

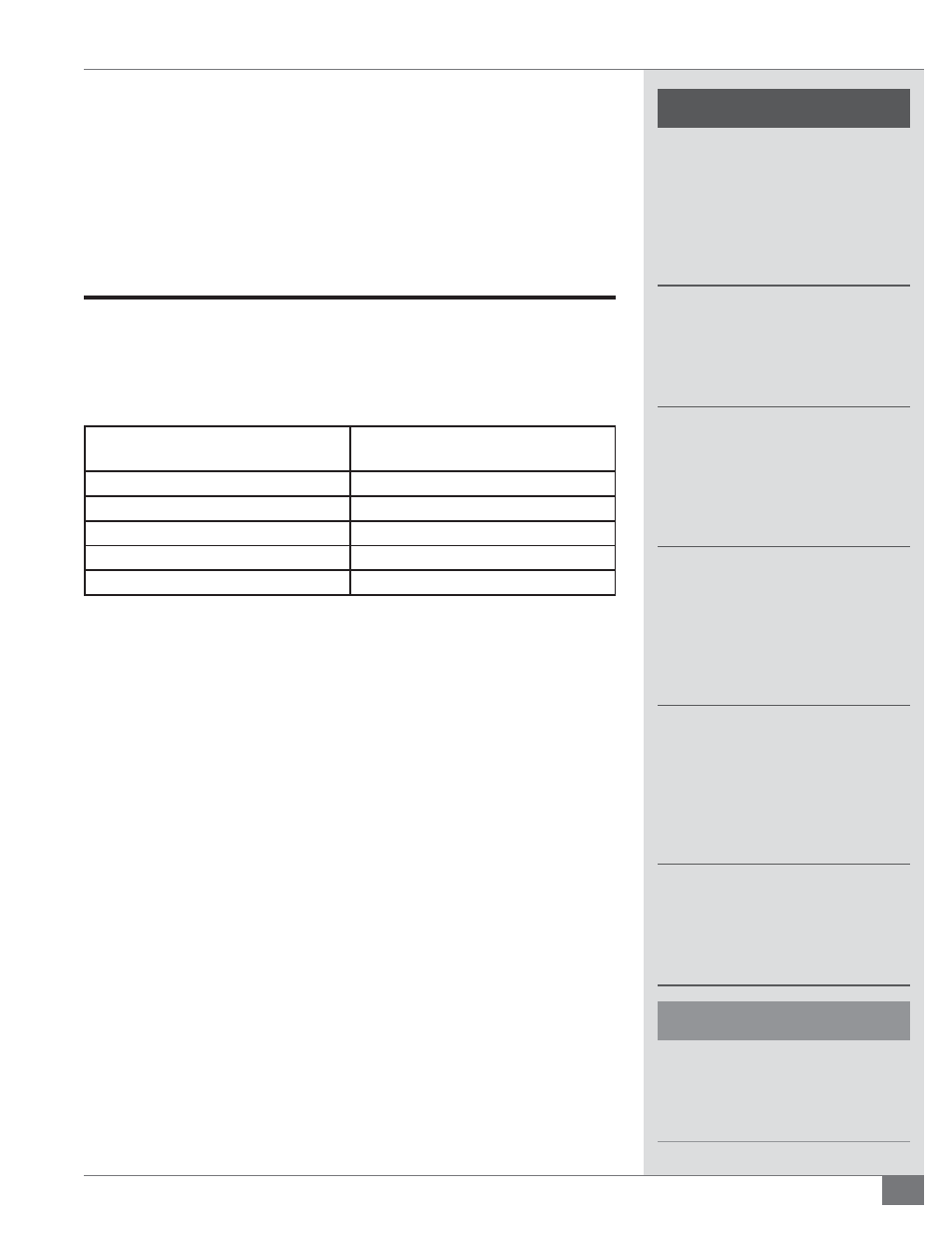

TABLE 4 - MINIMUM FLUE SIZES

Model

Minimum Flue Size

inches (mm)

6

6 (152)

10

6 (152)

15

8 (203)

20

10 (254)

30

12 (305)

The fl ue must be as large or larger than the outlet on the vessel. Avoid fl ue

piping and elbows by placing the equipment as close as possible to the chimney.

Adhere to the following for stack and fl ue installation (see Figure 3):

1. Ensure the stack rises continuously to the connection at the chimney and

contains no more than two bends at 45 degree angles or less. If required,

as a result of space limitations, one 90 degree elbow (or tee) can be fi tted

at the back of the vessel.

2. Ensure 2 feet (0.6 m) of straight, horizontal fl ue before any change in

direction, fi tting or draft regulator. This is to prevent potential pilot or

main fl ame failures due to back pressure build up during ignition. Any

alternative stack arrangement must supply negative 0.02 to 0.04”wc.

3. Ensure the run in the total distance of stack ducting, as measured in a

straight line from the outlet of the boiler to the outlet of the stack, does

not exceed 25% of the rise. With the exception of the duct run previously

described, horizontal sections of ducting must be avoided and should not

exceed 4 feet (1.2 m) total. See Figure 3.

4. Ensure the stack, chimney, and any components associated with the stack,

such as heat reclaimers or assist fans, are constructed from material that is

rated for a 1000 F (538 C) operating temperature.

5. Ensure the stack and chimney material complies with all applicable codes.

6. Make adequate provisions for the support of the weight of the chimney

and stack to avoid having a load imparted to the outlet connection of the