Appendix b: datastudio setup instructions – PASCO ET-8770 Energy-Transfer Friction User Manual

Page 12

®

Model No. ET-8770

Energy Transfer - Friction

11

Appendix B: DataStudio Setup Instructions

The instructions below outline the recommended experiment setup for PASPORT and

ScienceWorkshop sensors. Follow the steps specific for the type of sensor and interface (i.e.

PASPORT or ScienceWorkshop). (For a setup example, see “Sample Data” in this manual.)

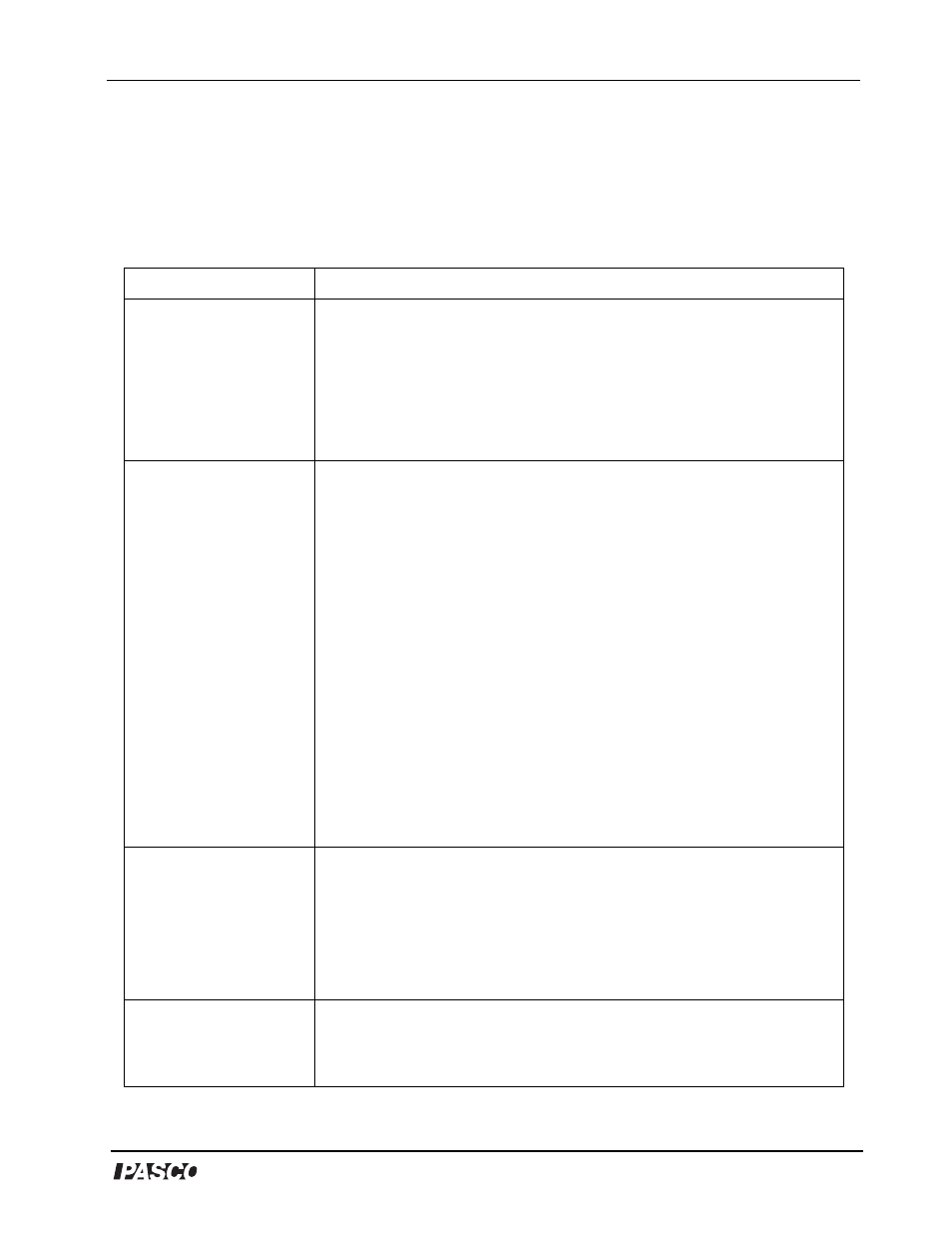

Procedure

Steps

PART I: Plug the

sensors into the

interface:

PASPORT: a) Plug the Force, Rotary Motion, and Temperature Sensors

into a PASPORT interface. b) Connect the PASPORT interface (i.e.

USB Link, PowerLink, etc.) to a USB port on your USB-compatible

computer. c) When the PASPORTAL window opens, select “Launch

DataStudio.”

OR

ScienceWorkshop: a) Plug the Force, Rotary Motion, and Temperature

Sensors into a

ScienceWorkshop interface. b) Launch DataStudio.

PART II: Set up your

experiment

PASPORT: a) In the Experiment Setup window, scroll to the Force

Sensor, select “pull, positive” and set the sample rate to 50 Hz. b) Scroll

to the Rotary Motion Sensor, select “large pulley, ” “linear velocity,” and

set the sample rate to 50 Hz. c) Scroll to Temperature Sensor, select

“Celsius” and set the sample rate to 2 Hz.

OR

ScienceWorkshop: a) In the Welcome to DataStudio window, double

click “Create Experiment.” b) In the Sensors list, click and drag the Force

Sensor, Rotary Motion and Temperature Sensor icons to channels on

the picture of the interface (i.e. to the same letters in which you have the

sensors connected.) c) In the Experiment Setup window, double click

on each of sensor icons to set the sample rate and select the

measurement units: i) Force Sensor - In the General tab, set the sample

rate to 50 Hz. In the Measurement tab, select “Force(N).” Click OK.

(Note: If calibrating, use the Calibrate tab to tare the Force Sensor at 0

Newtons.) ii) Rotary Motion Sensor - In the General tab, set the sample

rate to 50 Hz. In the Measurement tab, select “position(m)” and “velocity

(m/s).” In the Rotary Motion Sensor tab, select “1440” and “large pulley

(groove).” Click OK. iii) Temperature Sensor - In the General tab, set the

sample rate to 50 Hz. In the Measurement tab, select “C.” Click OK.

PART III: Create the

power and heat

equations

a) Power equation: Power=F*v, where F= force in Newtons and

v=velocity in m/s. b) Heat equation: Q=m*c*(max(T) - min(T)), where Q

= heat in joules, c=0.896 J/g

°

C for the aluminum cylinder (or 0.377 J/g

°

C for the brass cylinder), and T=the temperature in degrees Celsius.

[Select “data measurement” for the “F” and “v” and “T” variables. Create

an experiment constant for “m” (the mass) and “c” (the specific heat).

(For instructions, see Appendix C or the DataStudio online help.)]

PART IV: Collect Data

a) From the Data list, drag each of the parameters (i.e force,

temperature, power) over a y-axis in a separate graph display. b) Drag

the heat parameter to a Digits display. c) Click the Start button on the

main toolbar.