DYNAPACE Oven Exit Conveyor User Manual

Oxf 118, Adjustable oven exit conveyor

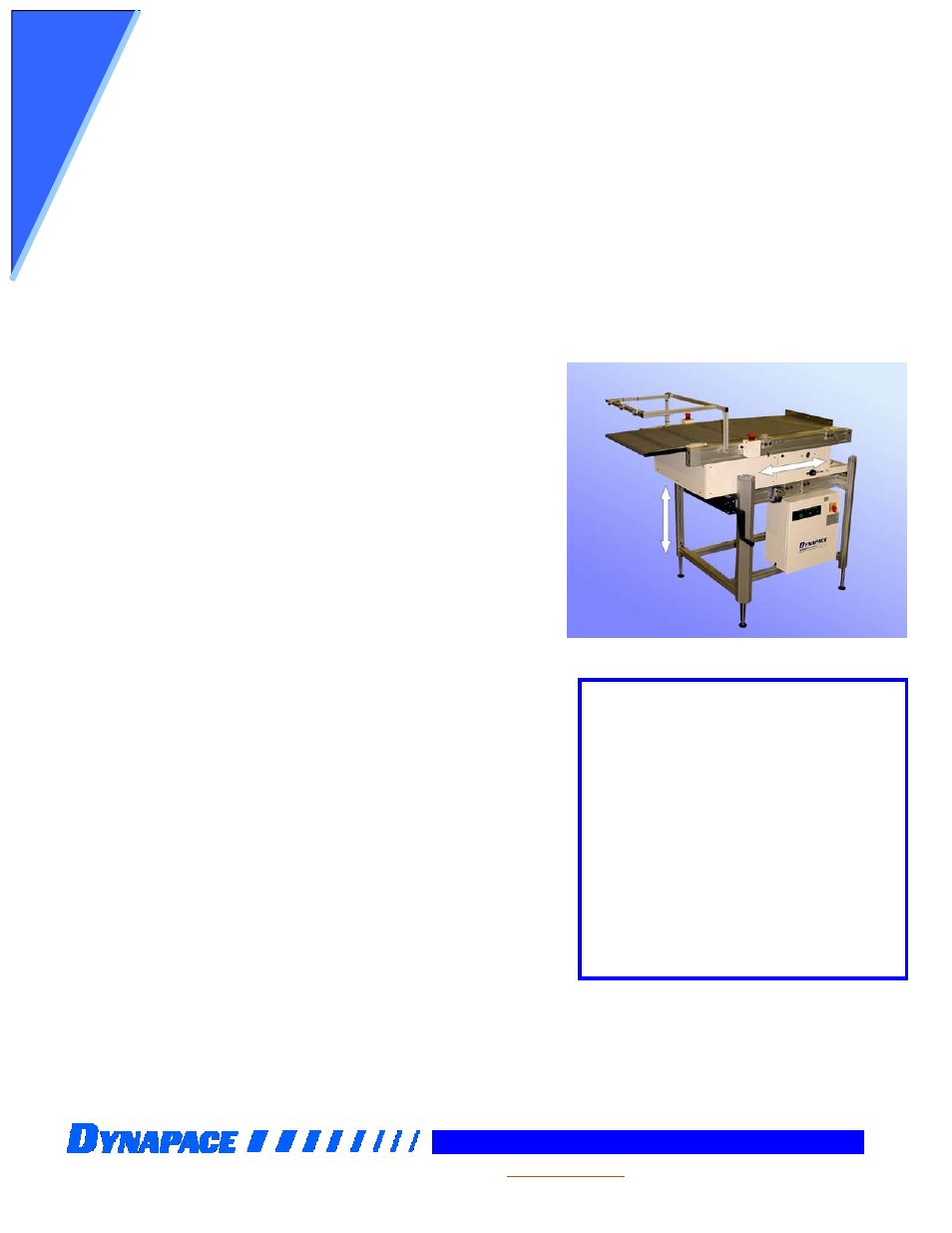

OXF 118

Adjustable Oven Exit Conveyor

P e o p l e a n d P r o d u c t s Y o u C a n R e l y O n

Module:

OXF-118 (18”W) Flat Belt Oven Exit Conveyor C17630

Frame Style:

Combination precision welded steel framing and extruded metal

Description:

The oven exit conveyor is designed to accept product exiting an oven on the mesh belt

or at a different height & position on the fingers. The OXF 118 adjusts for the correct

spacing for either chain or fingers. The flat belt design offers support to the full product.

Standard Features:

PLC control with indexing & belt full logic

Look down & look across sensors

EDS safe / high temperature belt utilized

Variable speed (1 - 12 fpm) (.30 – 3.66 mpm) others available

Stainless Steel Bed, Belt design offers support of full product

5/8th inch nose bar in the in feed

Operator controls (E-stop, Reset)

Left to right travel

Designed for longevity with minimal maintenance

Manual Position, height & in/out, adjustment standard

Power Position, with memory, adjustment optional

Painted sheet metal panels, “Dynapace White”

Conforms to SMEMA Spec. 1.2 and NFPA 79

Includes 1 standard communication cable

Product Handling Capability:

Edge Contact:

N/A

Length:

3” – 20” (76 – 508mm)

Width:

2” – 16” (51 – 406mm)

Thickness:

N/A

Weight:

9 lbs. (4.08kg) per foot

Available Options

Custom Lengths & Widths

Steel Frame

Multiple Drive Sections

Power height & in/out position

ts

Custom Colors

Light Tower & Audible Alarm

Cooling Hoods

ithout PLC

Continuous run w

Built in Storage & Tool Cabine

Facilities Requirements:

Electrical:

115 VAC/60Hz 15 amp

Air:

N/A

Footprint:

Approx.29”W by 48”L

737mm W by 1219mm L

PO Box 7 Palatine, IL 60078

•

847-398-5757

•

Sales Fax 847-852-3377

•

www.dynapace.com

082005