DYNAPACE Multi Lane Oven Loader and Unloader User Manual

Multi-track oven loader / unloader

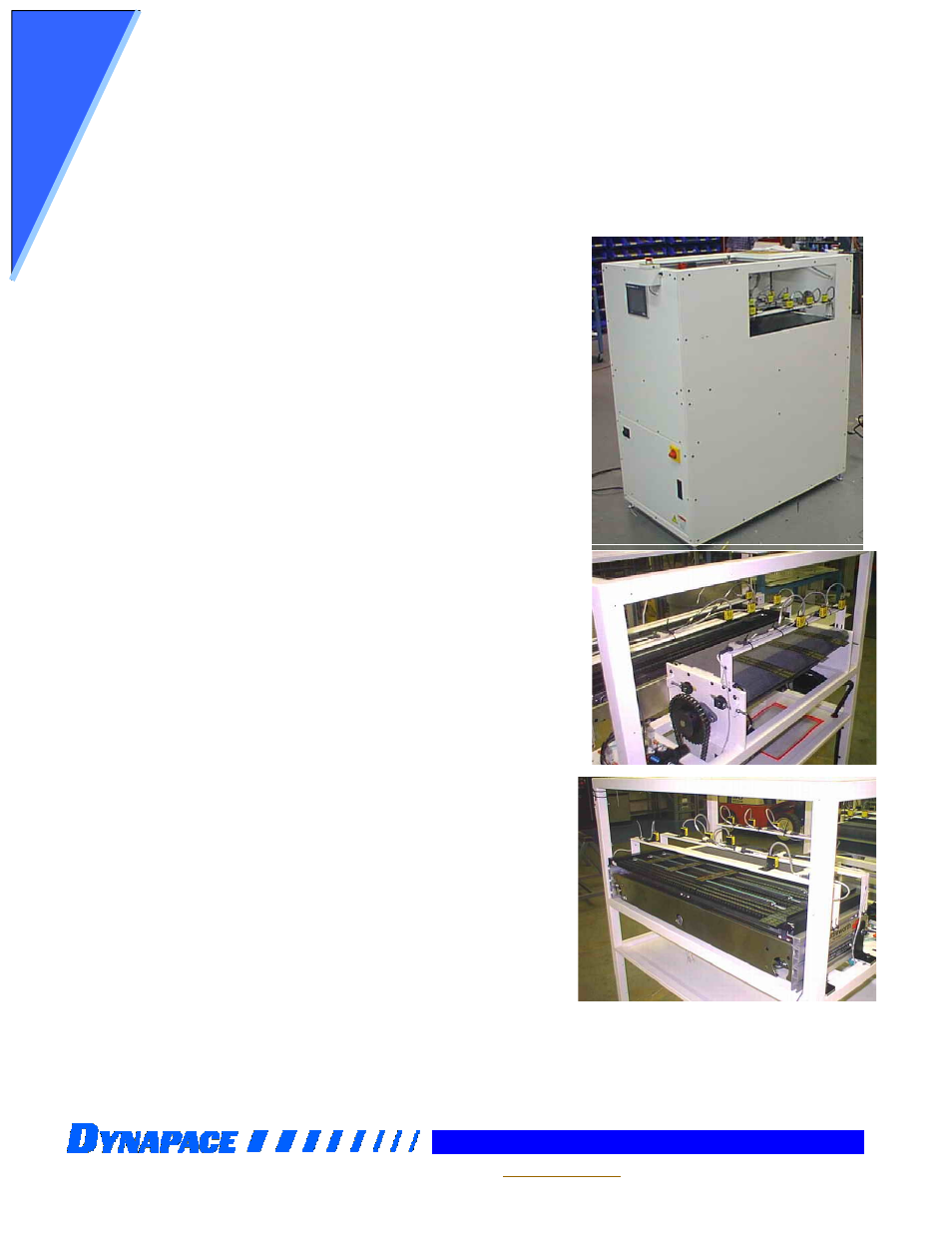

MTF 100 L / MTF 100 U

Multi-Track Oven Loader / Unloader

P e o p l e a n d P r o d u c t s Y o u C a n R e l y O n

Module:

MTF-100 L Multi-Track Loader / MTF-100 U Multi-Track Un-loader C17555

Description: The Multiple Lane Oven Loader receives individual

substrates from the upstream screen printer &

aligns several to load the oven in a multiple parallel

lane configuration. Since the unit has an input & an

output section, it continues receiving substrates

from the screen printer as it transfers substrates to

the oven.

S

tandard Features:

Roller conveyor & flat belt conveyor output

Number of output lanes dependent on width of product

Programmable Logic Controller

Variable speed (0 –20 mm/sec)

Advanced touch screen controls

Audible alarm / 1 color light tower

Left to right travel

Electrical enclosure door power disconnect switch

ESD grounding receptacles

Precision welded steel framing

Painted sheet metal panels, “Dynapace White”

Conforms to SMEMA Spec. 1.2 and NFPA 79

Includes 1 standard communications cable

Product Handling Capability:

Edge Contact:

NA

Length:

5” – 20” (127 – 508mm)

Width:

3.5” – 18” (89 – 457mm)

Weight:

Up to 5 lbs (2.7kg) per foot

Batch Width

22” (559mm) Custom Width Available

F

acilities Requirements:

Electrical:

115 VAC or 230 VAC at 50/60 Hz 15

amp @ 115VAC

Air:

Dry air, 50 psi

Line height:

37” +/- 1” (940mm +/- 25.4mm)

with 6” above floor clearance for utility track

Footprint:

C17555

24”L x 48"W x 68"H

(609mm L x 1219mm W x 1727mm H)

(including light tower)

PO Box 7 Palatine, IL 60078

•

847-398-5757

•

Sales Fax 847-852-3377

•

www.dynapace.com

C17167 082005