Vertical mounting, Friction disc replacement, Figure 7 parts for vertical mounting figure 8 – Dings Dynamics Group 1-70 Series180TC - 250TC User Manual

Page 8

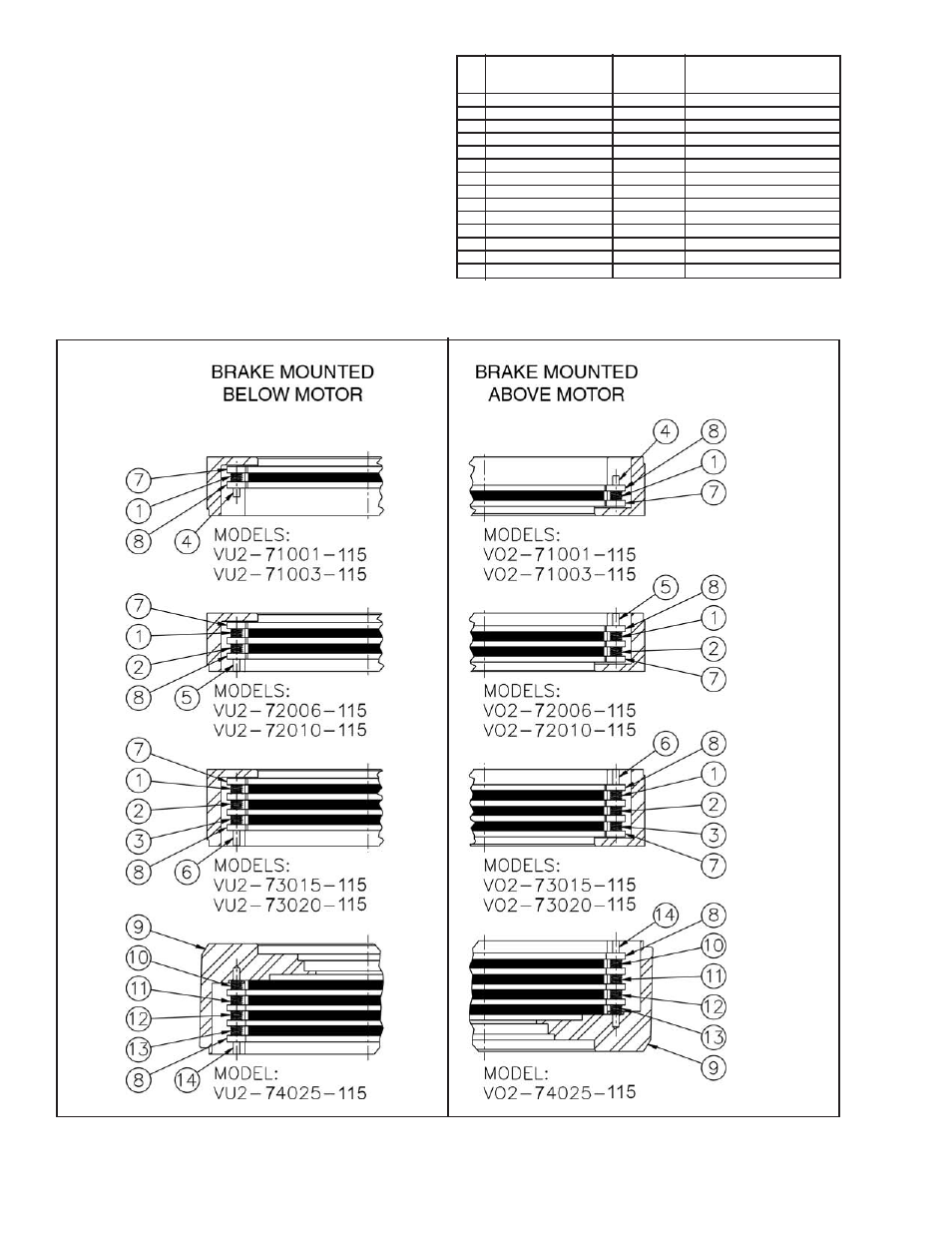

VERTICAL MOUNTING

Installation and adjustment of the vertically mounted brake is

the same as on the standard model.

Friction Disc Replacement

When replacing friction discs, follow procedure outlined on

page 5 with this addition:

Care must be taken to insure proper insertion of disc

separating springs. Springs are color coded for easy

identification, and reference is made to spring color (see

Figs. 7 and 8). Since the installation order of the disc springs

is dependent on brake mounting position (above or below

motor), it is important to consult the correct diagram for

spring location.

Qty. of Parts

Item

Part

(determined by no. of rotating discs)

No.

Description

No.

1

2

3

4

1

Spring (silver)

G060350-001

2

2

2

-

2

Spring (black)

G060350-002

-

2

2

-

3

Spring (bronze)

G060350-003

-

-

2

-

4

Roll pin-1/8” x 5/8”

W005003-071

2

-

-

-

5

Roll pin-1/8” x 1”

W005003-077

-

2

-

-

6

Roll pin-1/8” x 1 3/8”

W005003-080

-

-

2

-

7

Stationary disc

H060203-003

1

1

1

-

8

Stationary disc

H060203-004

1

2

3

4

9

Cast iron bracket (ref.)

-

-

-

-

1

10

Flotation spring (silver)

G060736-001

-

-

-

2

11

Flotation spring (black)

G060736-002

-

-

-

2

12

Flotation spring (bronze) G060736-003

-

-

-

2

13

Flotation spring (red)

G060736-004

-

-

-

2

14

Roll pin-1/8” x 1 3/4”

W005003-083

-

-

-

2

Figure 7 Parts for Vertical Mounting

Figure 8

8