Manual release adjustment, Manual release assembly – Dings Dynamics Group 1-70 Series180TC - 250TC User Manual

Page 7

Manual Release Adjustment

CAUTION: Load to be removed or blocked. Brake will be

inoperative during this procedure.

The manual release (3) may require adjustment after

replacing the operator assembly 15), magnet (15A0, or

armature (15J). It also may be required if adjustments are

made on the pivot stud nuts (19).

The release is working properly if:

a) you turn release knob (3) clockwise to stop and the

brake is released;

b) the release knob returns to its normal position

automatically when power is applied to the magnet.

NOTE: Cover (20) must be removed to make this adjustment.

1. To adjust: Set air gap “A” as described under “Wear

Adjustment” on page 4.

2. If the brake does not release, turn adjusting screw

(5) counterclockwise 1/4 turn and try again.

3. If the release knob (3) does not return to its normal

position automatically, turn screw (5) clockwise 1/4

turn and try again.

NOTE: You may have to repeat Steps 2 or 3 to get

the release to operate properly.

It is important that the release knob returns to its

normal position automatically when power is applied

to the magnet.

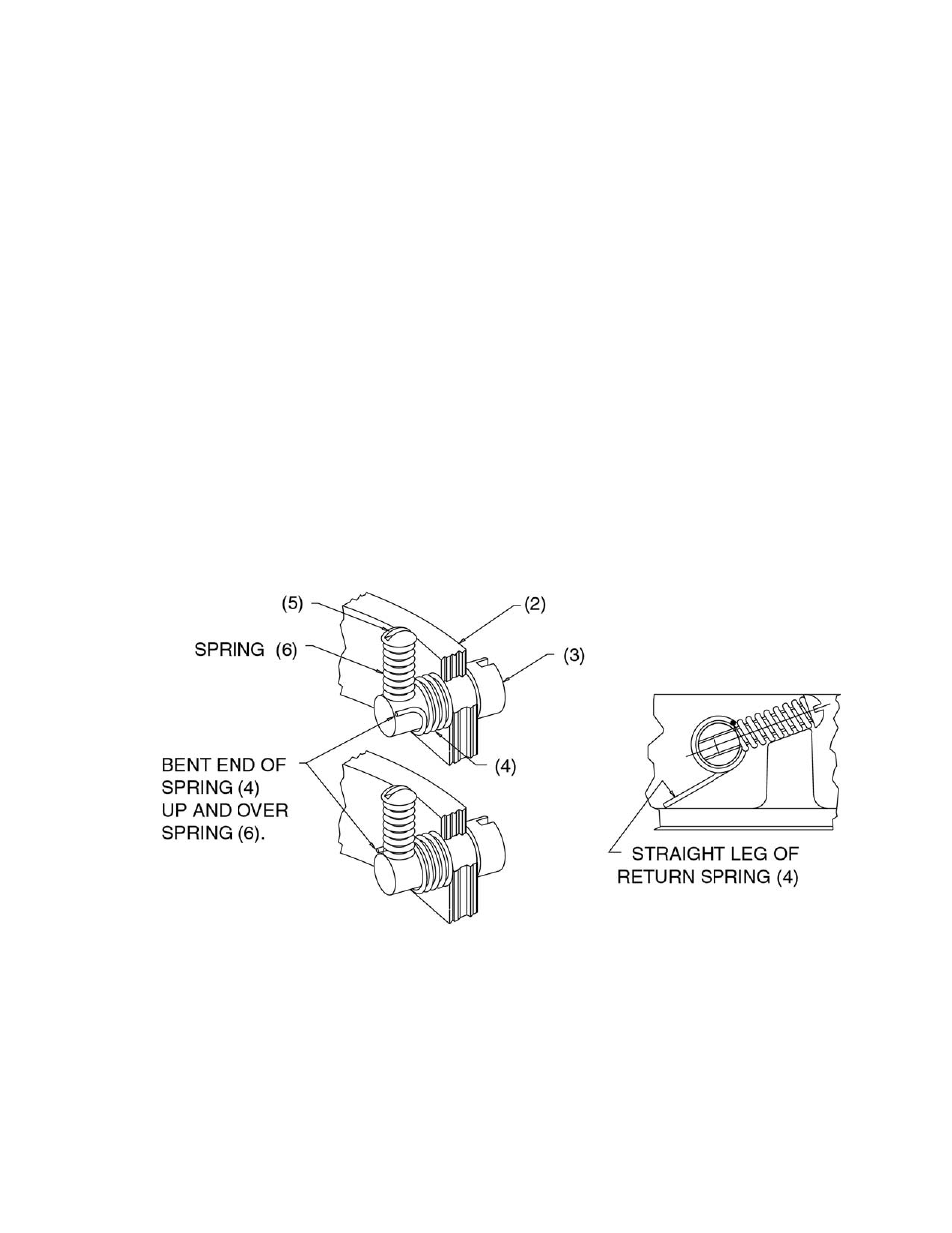

Manual Release Assembly

Refer to Fig. 6

1. Place shaft of release knob (3) through hole in

bracket (2).

2. Slide return spring (4) over shaft; straight leg of

spring should enter shaft first with leg in the position

shown.

3. Slip spring (6) over screw (5) and install in tapped

hole in release shaft. Screw in until it stops.

Make sure spring (4) is not caught under spring (6).

4. Engage bent end of spring (4) over spring (6) as

shown. Pull it over with a needle-nose pliers or

screwdriver.

5. Adjust release. See “Manual Release Adjustment” on

the left.

Figure 6

7