Dings Dynamics Group 5600 Style 56C - 145TC User Manual

Dings Dynamics Group For the car

Bulletin No. BK4684 (1/11)

DESCRIPTION

This brake is direct acting, electromagnetically released and spring set.

It uses rotating and stationary disc contact to supply positive braking action.

It retains quick release and setting capabilities at all times. Simplicity of design

has reduced maintenance to an absolute minimum. As with any electro-

mechanical equipment, however, periodic inspection and adjustment will assure

optimum performance. As the friction disc wears, the magnet gap will increase.

The magnet gap should be checked periodically and adjusted when necessary.

WARNING: Do not install or use these brakes in an

explosive atmosphere.

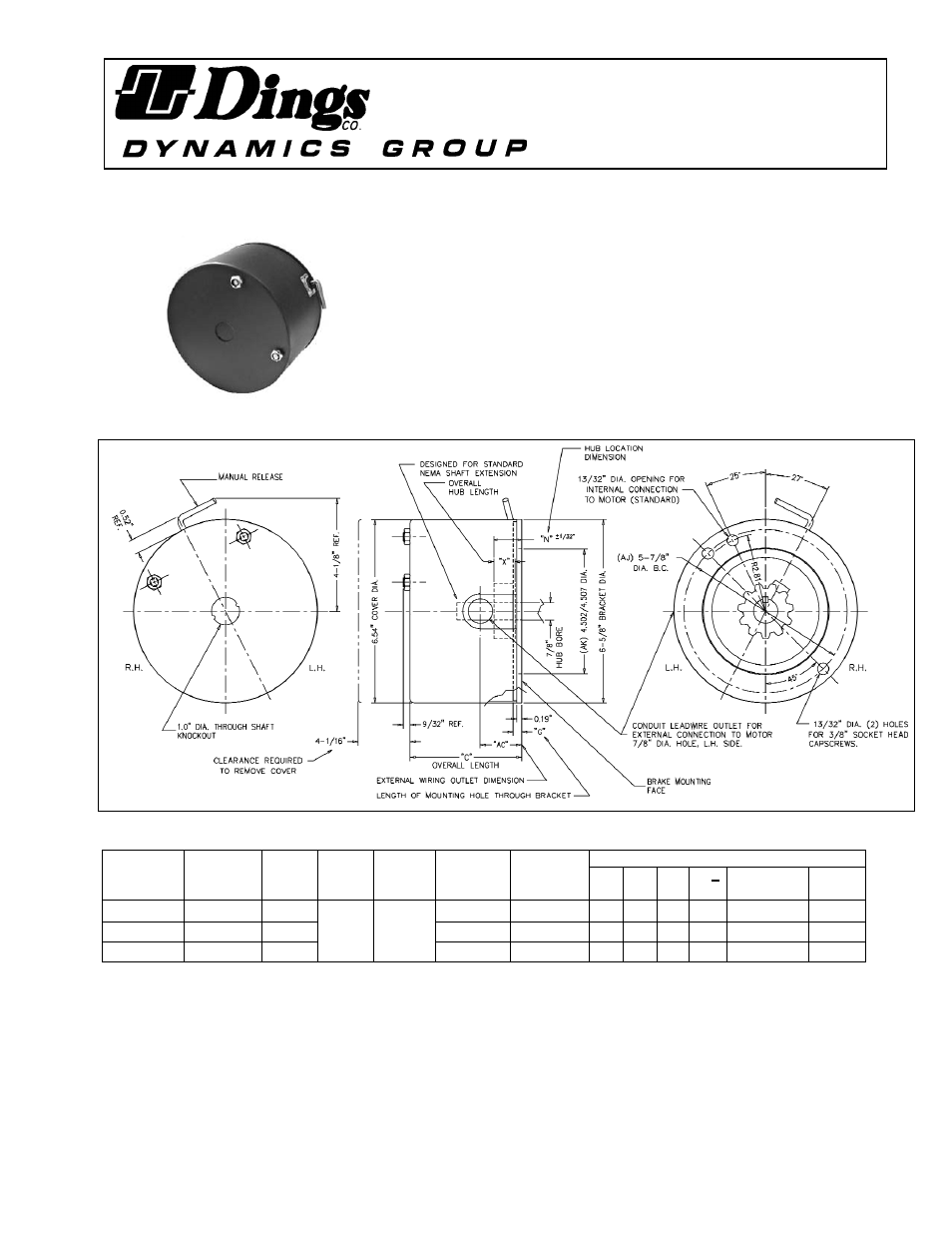

Figure 2. Outline Drawing (does not include kit components)

Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself

and others by observing all safety information. Failure to comply with instructions could result in personal injury

and/or property damage! Retain instructions for future reference.

**Thermal capacity (HPS/MIN.) was determined under the following test conditions: a) Room temperature 72

o

F. b) Stopping time of one second or less.

c) Brake mounted in a horizontal position. d) Equal on and off times. e) 1800 RPM f) Coil energized with 110% of rated voltage.

G061084-001

Figure 1. 5600 Style Brake

Table 1. Brake Specifications

1

www.dingsbrakes.com

60 Series End Mount

Brake Instructions

NEMA 2 Enclosure

* Last digit of model number

1 = With both manual release and external wire outlet

2 = With manual release and without external wire outlet

3 = Without manual release and with external wire outlet

4 = Without both manual release and external wire outlet

Model

Number

Number of

Rotating

Discs

Torque

lb-ft

Motor

Frame

Housing

Material

**Thermal

Capacity

HPS/MIN

Inertia of

Rotating

Parts Lb-ft

2

Dimensions

X

G

C

N +

1/32

Air Gap

Min.

Air Gap

Max.

61003-560*

1

3

56C

Steel

6

0.006

0.81 0.31 4.01 1.00 0.045/0.060

0.220

61006-560*

1

6

6

0.006

0.81 0.31 4.01 1.00 0.045/0.060

0.220

62010-560*

2

10

6

0.010

0.81 0.31 4.01 1.00 0.050/0.065

0.220