Dings Dynamics Group 56C 405TC frame User Manual

Direct-acting brakes

Direct-Acting Brakes

F

Fo

orr M

Ma

arriin

ne

e,, M

Ma

arriittiim

me

e,, a

an

nd

d N

Na

av

vy

y A

Ap

pp

plliic

ca

attiio

on

ns

s

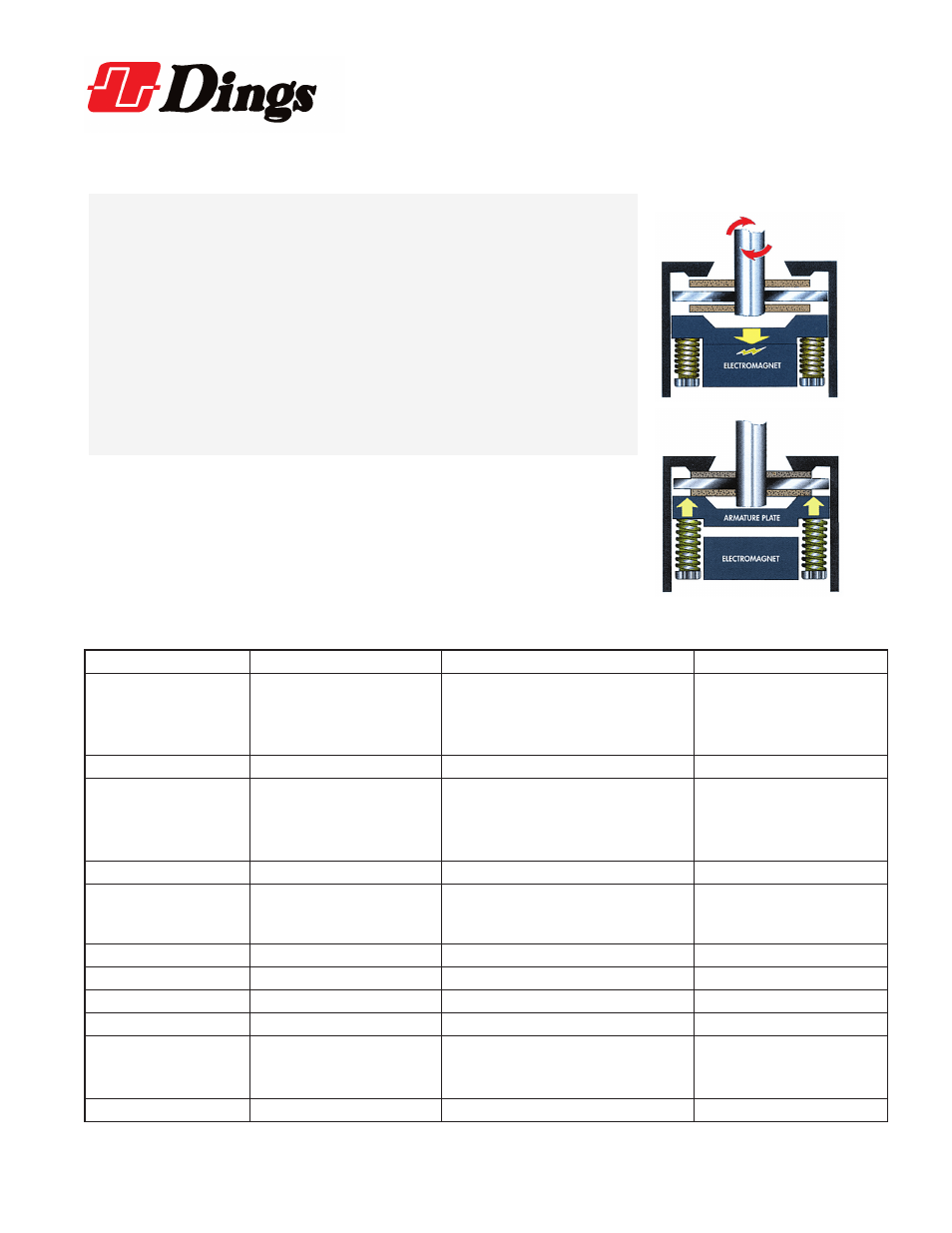

Operation

Our brakes operate on a very simple principle:

While the motor is running with power engaged, an electro-

magnet within the brake pulls back the pressure plate, allowing

the friction discs and motor shaft to rotate freely.

When power is cut to the motor, the electromagnet releases,

instantly stopping the rotating discs and preventing the motor

shaft from turning.

This direct acting design has only one moving part with no

complicated linkages to break or fail.

Built for Harsh Environments:

• Cast iron or ductile iron enclosures for strength & durability

• Marine finish and plating to prevent corrosion

• Splined hub and friction disc for added durability

• Drains and heaters available to eliminate moisture

• Stainless steel or aluminum bronze component options provide additional corrosion resistance

Type of Service

Maritime

Marine

Navy

Description

Designed for non-military

shipboard and seawater

environment applicatoins

For shipboard and seawater

environment applications.

Designed to be similar to military

specifications

Designed in accordance

with Military Specifications

Specifications

IEEE45*

IEEE45* & Similar to MIL-B-16392B

MIL-B-16392B

Brake Series

60 Endmount & Coupler

70 Endmount & Coupler

80 Endmount

90 Endmount

60 Endmount & Coupler

70 Endmount & Coupler

80 Endmount

90 Endmount

70 Endmount

80 Endmount

Enclosure

IP56 / NEMA 4X

IP56 / NEMA 4X

IP56 / NEMA 4X

Paint

Humidity & Moisture

Resistant Self-Priming

Epoxy Coating

Primer & Top Coat per TT-P-645 &

MIL-DTL-15090

Primer & Top Coat per TT-

P-645 & MIL-DTL-15090

Enclosure Material

Cast Iron

Cast Iron

Ductile Iron

Pressure Plate

Plated Steel

Plated Steel

Plated Steel

Stationary Disc

Steel

Steel

Aluminum Bronze

Splined Hub & Disc

Yes

Yes

Yes

Manual Release Type

Maintained with

automatic reset

Maintained with automatic reset

Non-maintained, deadman

External release lever

Coil Insulation

Class B**

Class B**

Class B**

* If full IEEE45 compliance is required, IEEE45 nameplate must be requested.

** Depending on phase and torque, brake may have Class H coil(s) as standard.

BR0001

11/2010