Mp pumps hto series operation and maintenance – MP Pumps HTO 120 INSTALL User Manual

Page 3

MP PUMPS HTO SERIES

OPERATION AND MAINTENANCE

Thermal oil vapors leaking from a system can be

highly flammable.

Any system leak should be repaired immediately.

Do not insulate the pump or system piping with

porous flammable insulation. Fluid may wick,

decompose and spontaneously ignite.

Ideal mechanical seal life is 20,000 hours.

Reduced seal life may be experienced from

extreme conditions.

Recommended spare parts and service parts to

rebuild the HTO-120 are:

At disassembly, check the impeller and other wear

items for unusual wear. Replace if necessary.

When servicing the pump, care should be taken

that the pump has cooled to a sufficient

temperature to permit disassembly. The product

should be drained from the pump housing and

disposed in accordance with the fluid

manufacturer's recommendations. Operating

personnel should be warned to exercise care and

utilize eye and skin protection when servicing the

pump.

PART NO.

DESCRIPTION

QTY.

29781

DRIVE SLEEVE

1

25662

GASKET

1

29158

ISOLATOR

2

29774

LIP SEAL

1

29773

SEAL ASSEMBLY

1

29165

GASKET

3

29230

O-RING

1

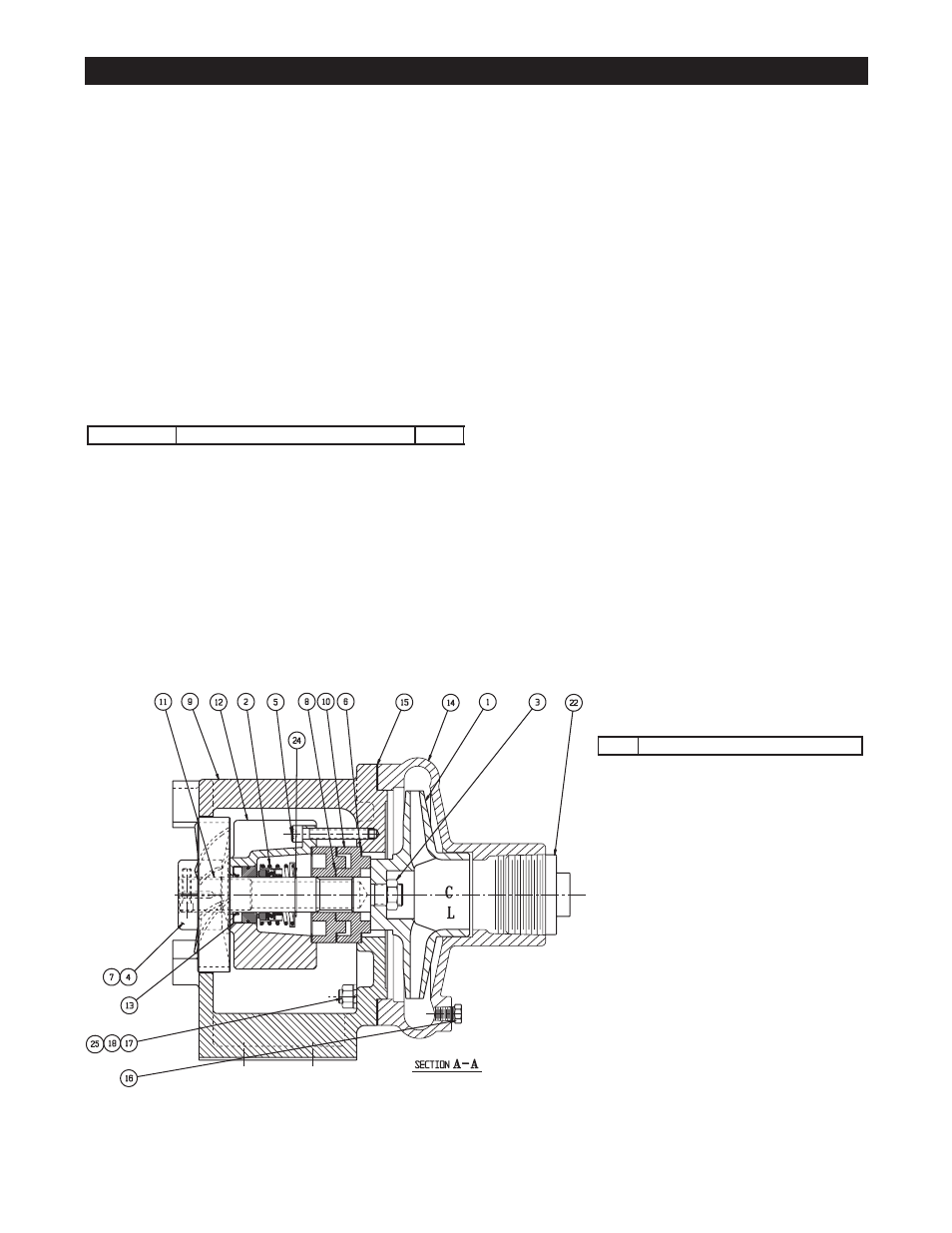

HTO PUMP CROSS-SECTION AND DETAIL

DET.

DESCRIPTION

1

IMPELLER – CAST IRON

2

SEAL ASSEMBLY 1”

3

HEX JAM NUT – S.S.

4

COOLING FAN CLAMP

5

CAPSCREW STL

6

GASKET - KLINGERSIL

7

CAPSCREW STL

8

O-RING - VITON

9

ADAPTOR – DUCTILE IRON

10

ISOLATOR – CARBON GRAPHITE

11

DRIVE SLEEVE – STAINLESS STEEL

12

SEAL HOUSING – DUCTILE IRON

13

LIP SEAL - VITON (CR#9937)

14

HOUSING – DUCTILE IRON

15

GASKET

16

PIPE PLUG S.S. 1/8 N.P.T.

17

LOCKWASHER S.S

18

STUD 3/8-16 X 1.63

20

HTO WARNING STICKER

(NOT SHOWN)

22

PIPE PLUG 2” NPT

24

SNAP RING - STL

25

HEX NUT 3/8-16

- 2 -

- 3 -