MP Pumps FRX-75 INSTALL User Manual

MP Pumps Pumps

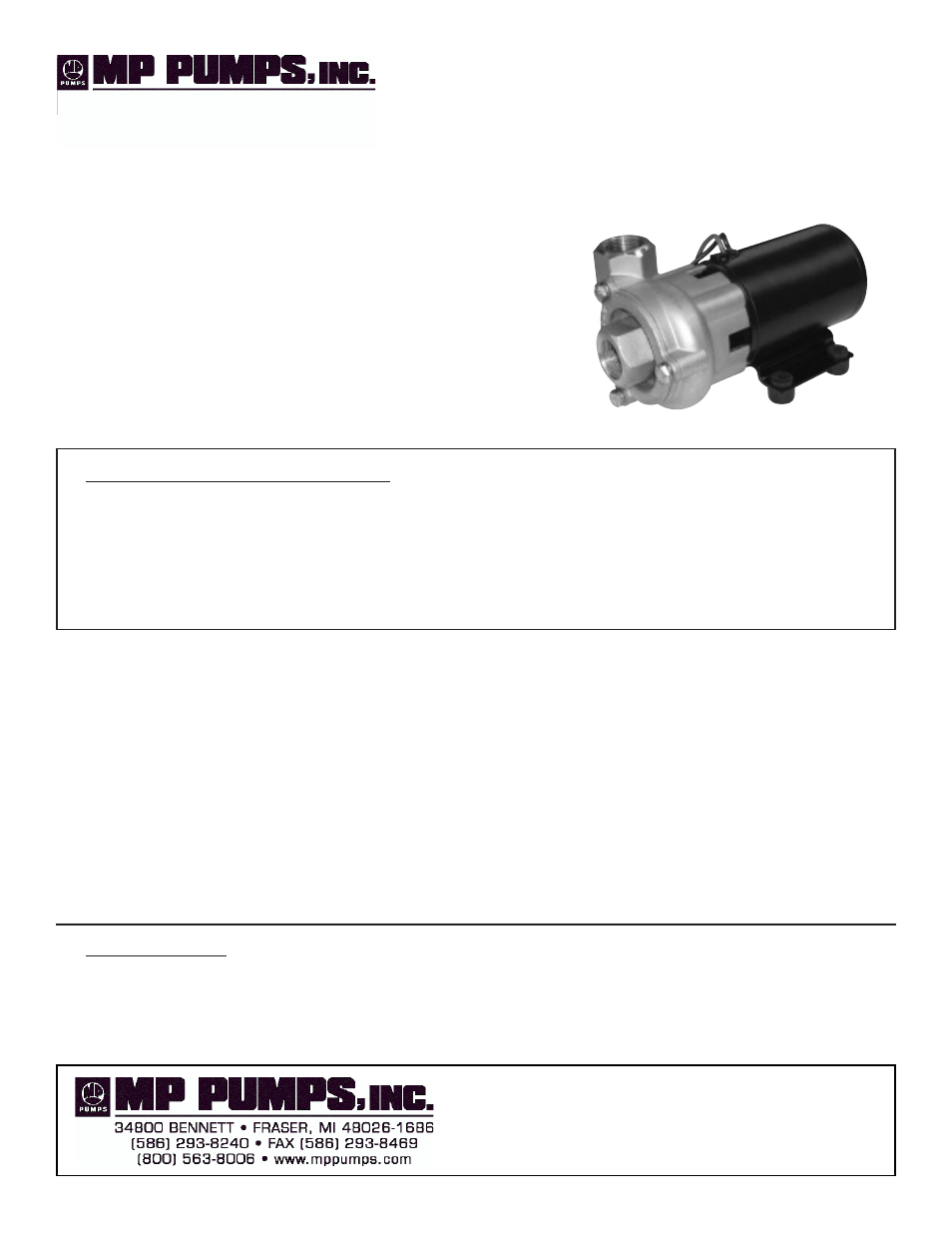

FRX 75 is a high performance stainless steel centrifugal

pump. Its uses are marine, commercial, and industrial

transfer of chemicals or potable water. FRX 75 features

a totally enclosed long life, ball bearing, 12VDC motor

with marine ignition protection. All pump parts are

316 stainless for superior corrosion resistance when

pumping chemical compounds, A carbon, ceramic, viton,

bellows shaft seal is standard. 3/4 inch NPT

flanges and base mounted vibration isolators simplify

installation.

®

®

FORM 3805A (05-04)

FRX 75 316 STAINLESS STEEL CENTRIFUGAL PUMP

INSTALLATION, OPERATION, AND REPAIR MANUAL

GENERAL SAFETY INFORMATION:

THE FOLLOWING WARNINGS ARE USED TO NOTIFY AND ADVISE THE USER OF THIS PRODUCT OF

PROCEDURES THAT MAY BE DANGEROUS TO THE USER OR RESULT IN DAMAGE TO THE PRODUCT.

THIS BULLETIN MUST BE READ COMPLETELY BEFORE INSTALLING, OPERATING, OR SERVICING,

THE PUMP.

INSTALLATION:

Install the pump where the inlet is below the liquid level. A valve may be used to isolate the

pump for service. The pump is not self-priming and needs the inlet to be flooded at start-up.

The motor is splash resistant, not submersible, and should be located in a dry environment.

• DO NOT perform service or maintenance

when the pumping system is pressurized.

Injury or death may occur.

• DO NOT operate the pump in a manner

that it was not intended to be used.

• DO NOT mount the pump such that high

piping loads exist on the pump flanges, or

in a rigid piping system that does not allow

the pipe to expand and cause the pump to

be strained.

• DO NOT continue to operate the pumping

system when a known leak exists.

• DO NOT continue to operate the pump

when unusual noise or vibration occurs.

• DO NOT operate beyond the pressure or

temperature limits stated in the product

literature. See Form 8110.

• DO NOT allow severe temperature changes

to occur in a short time period within the

pumping system.