MP Pumps S300, S600, S700, & FM40 PUMPS INSTRUCTION User Manual

Page 4

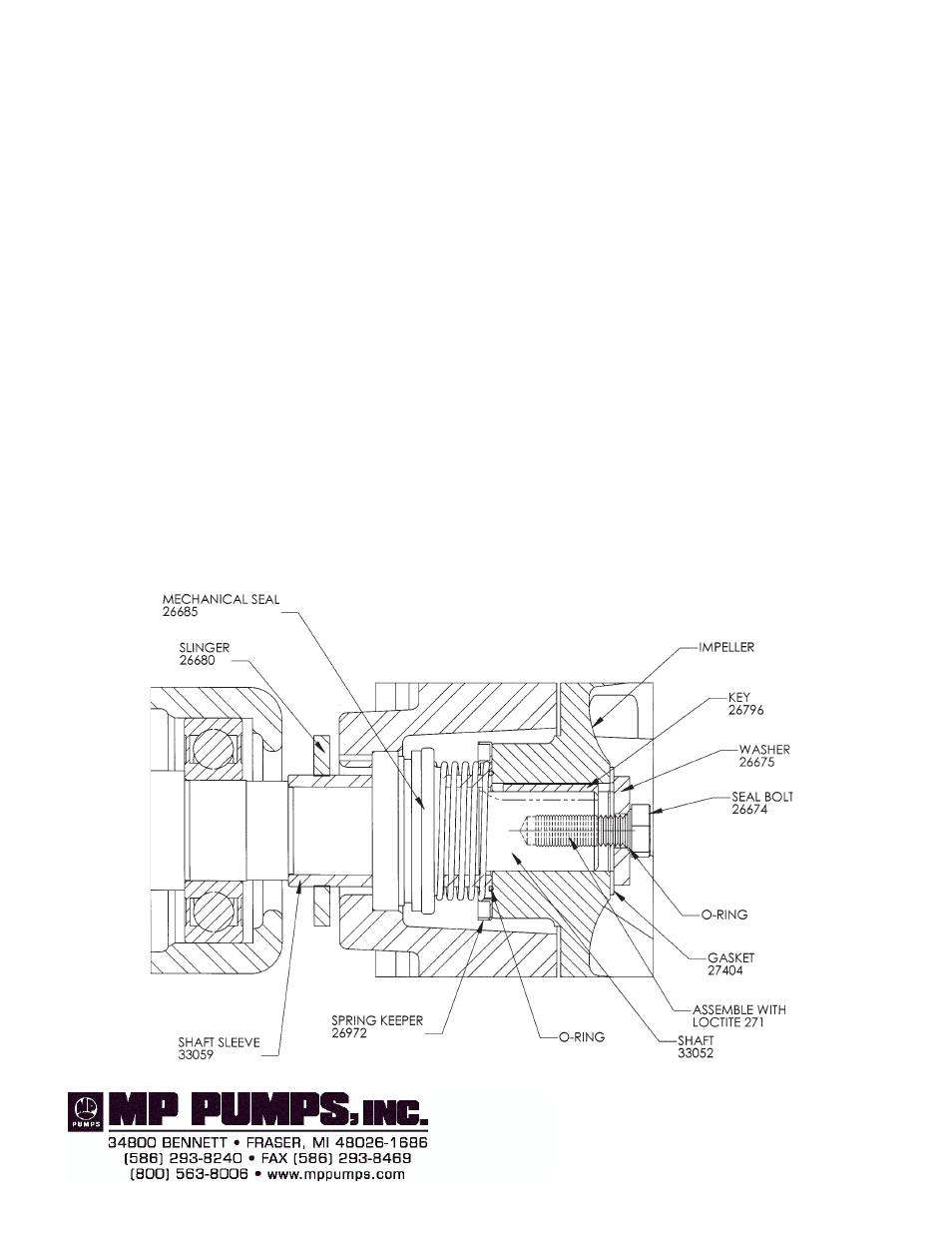

Put the seal spring over the shaft and onto the seal.

Slide the impeller over the shaft and hold it in place by

hand. Then thread the front seelbolt assembly into

the shaft. Hold the impeller and tighten the seelbolt to

a torque of 15 foot pounds.

Put the pump housing gasket over the seal adaptor

and replace the housing using the eight capscrews and

lockwashers that were previously removed.

Install the drain plugs in the housing if they were

removed. Install the jackscrews in the threaded holes

in the body. They should be tightened just enough to

keep them from falling out.

ADJUSTING IMPELLER END CLEARANCE -

For pedestal mounted pumps: Loosen the shaft sleeve

clamp and use a tool to push the impeller back, from

the inlet of the pump, far enough to insert a piece of

.020-.025” shim stock between the end of the

impeller and the wear plate. Release the impeller and

tighten the three hex head capscrews on the drive end

of the pedestal assembly. The three dog point set

screws can then be tightened and locked in place with

the three hex nuts. Remove the shim stock from

between the impeller and wear plate.

LUBRICATION - The liquid being pumped lubricates the

shaft seal. No additional lubrication is required.

Rotating equipment such as electric motors or engines

used to drive the pump should be lubricated in

accordance with the manufacturer’s instructions.

Pumps with grease lubricated bearings do not require

lubrication as the bearings have been pre-lubricated at

the factory.

WEAR RING - Series 700 pumps are provided with a

wear ring in the housing. The Series 300 and FLOMAX

40 do not use wear rings. The wear ring is a press fit in

the housing. If it is worn to the point of replacement it

must be cut with a chisel and deformed to be removed.

A new wear ring must be pressed into place using an

arbor press and a cylindrical tool or heavy flat plate of

the approximate OD of the wear ring. The important thing

to remember when installing the wear ring is to press it

in squarely. Then it will go in easily. If it is misaligned

slightly, it will be very difficult to press into place.

FIGURE 1

FORM 3021-D (10/04)

4