Troubleshooting chart – Magnum Venus Plastech UltraMAX HVLS-1000 Series User Manual

Page 32

HVLS-1000 Series Fluid Section Manual

Rev. 05/2012

Page | 32

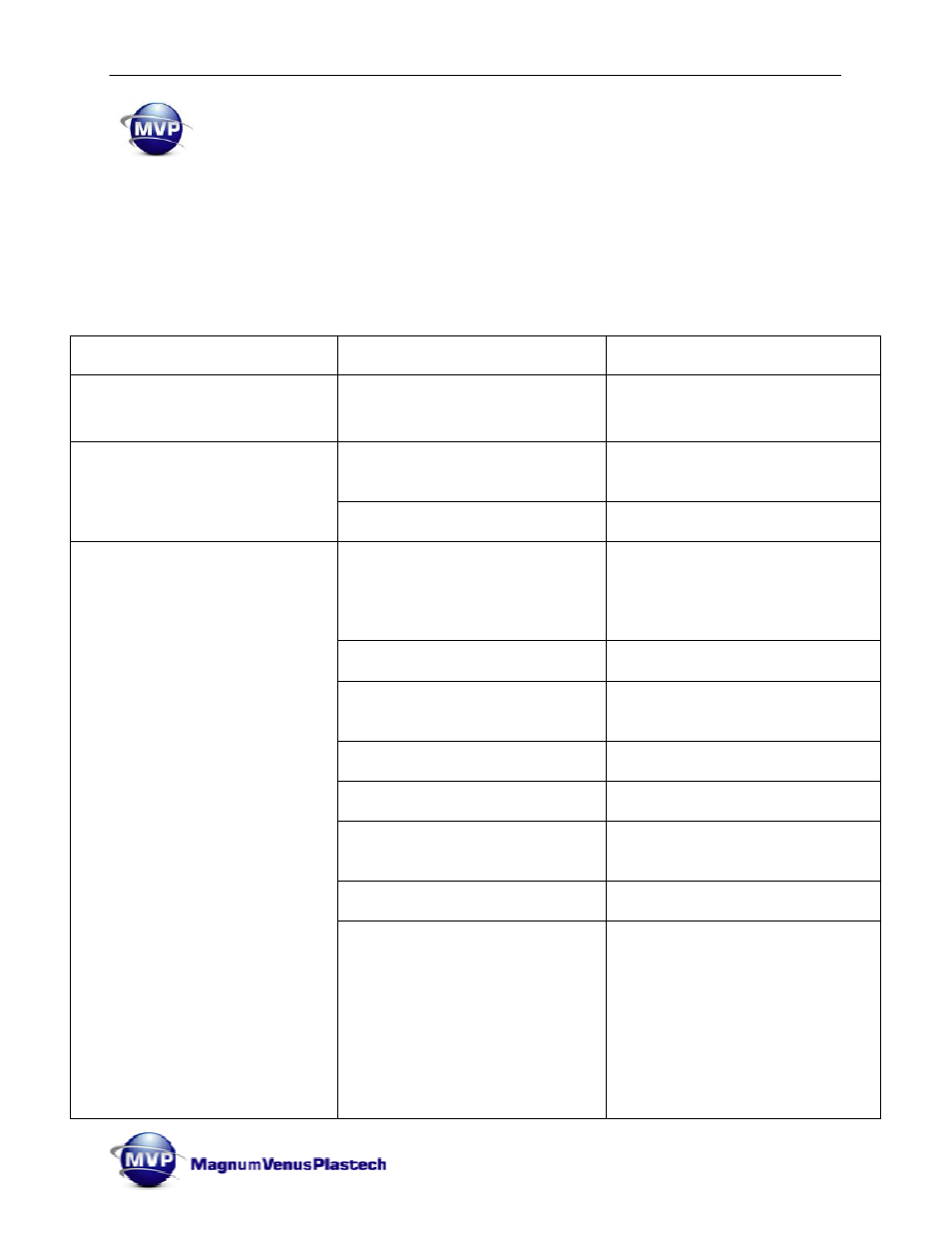

Troubleshooting Chart:

DIAGNOSING PROBLEMS:

The most common problems with the equipment are diagnosed by analyzing the cured part.

NOTE: Many problems are the direct result of a failure to maintain the equipment according

to the maintenance schedules given. Please follow your maintenance chart.

PROBLEM

CAUSE

SOLUTION

Slow cure during upstroke

S.S. Ball in catalyst pump piston

body not seating

Clean ball and inspect seat.

Replace ball, piston seal or piston

body if questionable.

Slow cure during down stroke

S.S. Ball in catalyst pump inlet

body not seating.

Clean ball and inspect seat.

Replace ball or have seat

repaired if questionable.

Catalyst Check Valve (CV-2000)

not working correctly.

Check and Repair the Catalyst

Check Valve (CV-2000).

No cure or slow over-all cure

Catalyst pump set at too low or

too high of a percentage.

Move catalyst pump to a higher

setting (closer to the gel coat

pump). Be sure to attach the

catalyst pump in a vertical

position.

Catalyst supply below outlet

fitting on jug.

Fill catalyst jug 1/3 full.

Catalyst drive not engaged or

connected

Install quick pin. Be sure to

attach the catalyst pump

vertically.

Catalyst leak.

Check all fittings. The catalyst

system must be fluid tight.

Catalyst relief valve on catalyst

pump is leaking.

Relieve pressure from pump.

Clean and repair the Relief Valve

Catalyst suction screen in

catalyst jug clogged.

Clean catalyst suction screen and

ensure that catalyst supply is not

contaminated.

Air lock in catalyst pump.

Remove air lock. See Appendix:

Air Lock in the Catalyst Pump.

Catalyst pump piston seal worn

or damaged

Replace piston seal. During

reassembly, be sure spring in

seal faces top of pump