Installation overview – Liquid Controls LCR Install User Manual

Page 4

4

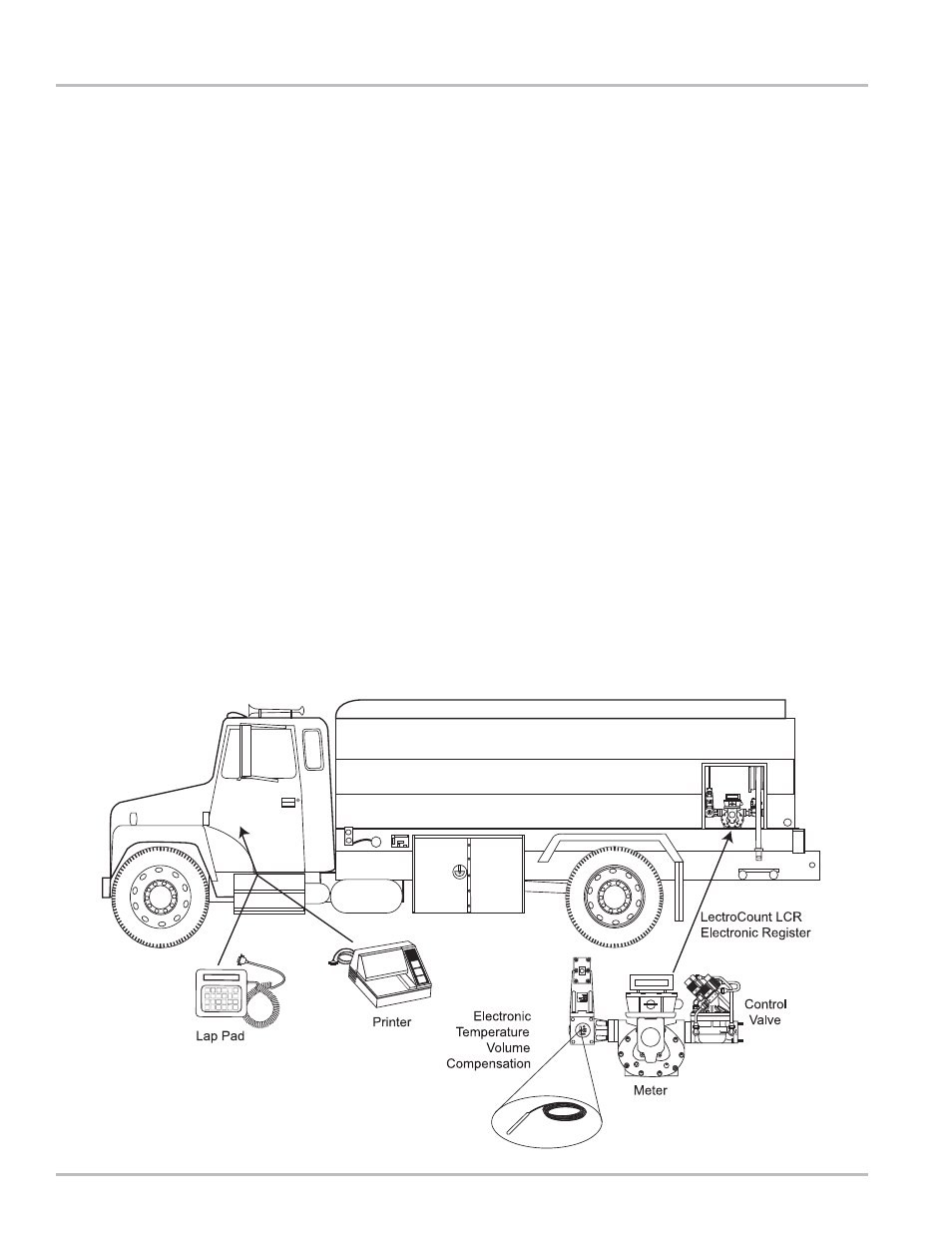

Installation Overview

Meters with LCR (factory installed)

In many instances, the LCR will be factory installed on a

Liquid Controls meter, along with a strainer/air eliminator

and security valve. In such cases, the user may proceed

to page 10 of this manual “Wiring the LCR” after verifying

that the truck electrical system meets the specifications

listed below.

Field retrofit of LCR to existing meters

For field installation of the LCR to a meter the steps listed

below, and described in this manual, should be followed.

A typical truck installation includes the following steps:

•

Ensure that the truck electrical system meets

specifications

•

Remove existing mechanical registration equipment

•

Remove manual preset valve

•

Install an electronically controlled security/preset

valve

•

Mount LCR to the meter

•

Install optional peripheral accessories including

electronic temperature/volume

compensation (ETVC) kit, odometer pulser, remote

START/STOP switch, etc…

•

Route factory supplied cables from LCR to truck cab

•

Mount printer in cab

•

Connect printer and LCR to truck’s

accessory circuit (12 VDC)

Electrical check for Truck Installations

Before beginning the installation, make sure that the truck

electrical system meets the minimum requirements to

correctly power the LCR. The truck system should

produce at least 12.6 VDC to reliably power the LCR

and the valve control solenoids. Truck systems that do

not meet this requirement need to be serviced to ensure

that the LCR will be reliably powered. The LCR computer

will power down if the voltage drops below 9 VDC.

The truck system must meet the following requirements:

•

Make sure that, with the truck running at low idle

and ALL accessories on (including the hose reel),

the voltage does not drop below 9 volts.

•

Be sure that all radio antennas have been installed

in accordance with the manufacturer’s specifications

to prevent RF interference.

NOTE

: The LCR power cable kit includes a fuse holder

and a 5 Amp fuse to protect the truck system in the event

of a short circuit in the cable. Liquid Controls

recommends that this fuse be used in all installations

not having a fused accessory block to protect the truck

in the event of cable faults. A 5 Amp fuse is required.