Wiring the lcr – Liquid Controls LCR Install User Manual

Page 11

11

Wiring the LCR

General

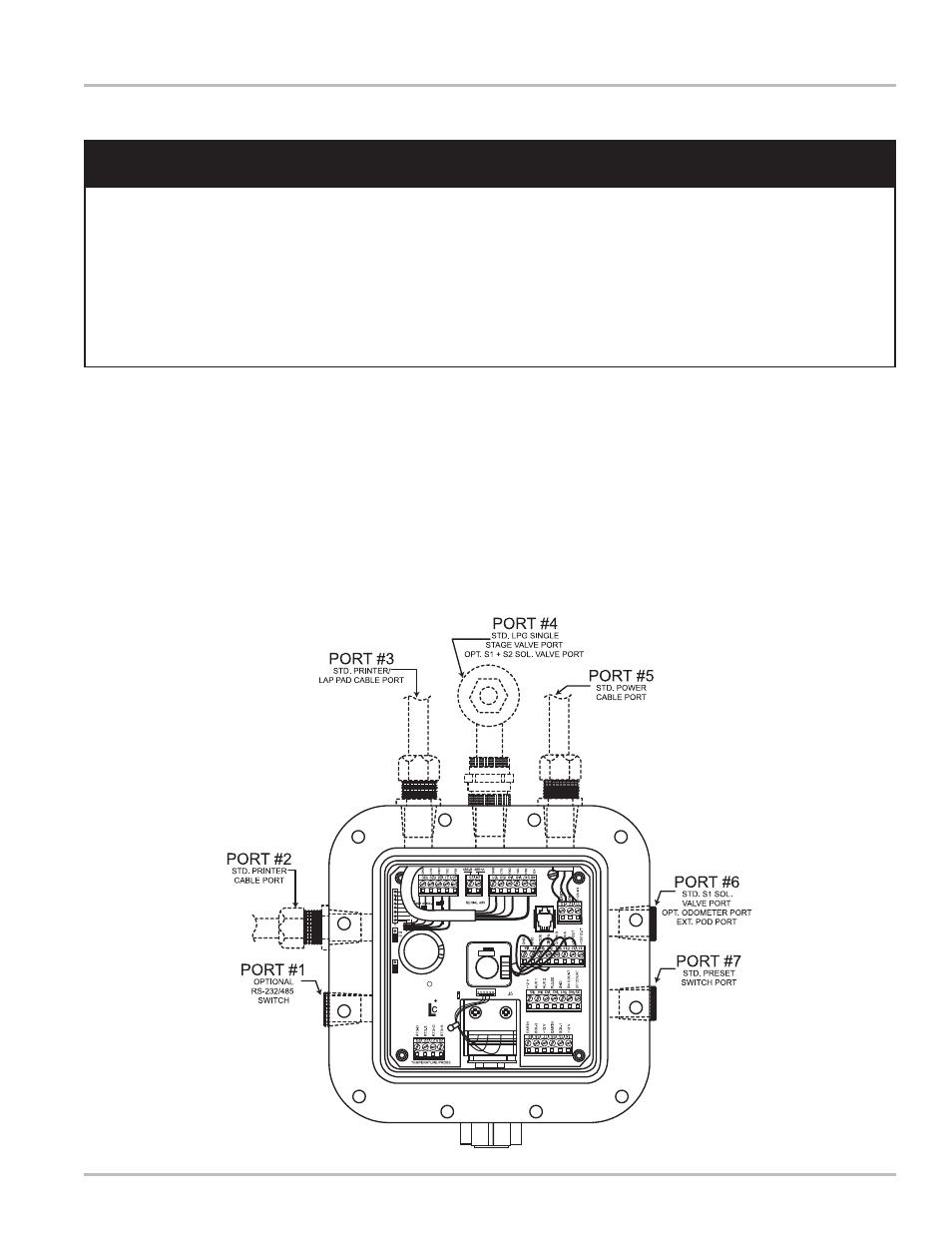

Once the LCR, and optional equipment such as control valve and ETVC kit have been installed in accordance with

instructions supplied with the units, wiring connections need to be made from those components to the LCR. The user

supplied wiring for all connected equipment must be routed through suitable conduit to the LCR. Threaded pipe

conduit, Liquid Tight, and Synflex are among some choices. If plastic Synflex fittings are used, make sure that they are

rated for outdoor use, temperature and gas/oil service. The conduit hubs on the LCR are all 1/2” - 14 NPT. Recommended

conduit routings are shown to the right. For your convenience in wiring, all terminal blocks on the LCR are removable

by pulling straight up. CAUTION: The conduit/cable entrances must be sealed inside and out using appropriate cable

glands to prevent moisture from entering in the LCR.

!

!

!

!

!

WARNING

WARNING

WARNING

WARNING

WARNING

Power, input and output (I/O) wiring must be in

accordance with the area classification for which it is

used (Class I, Div 2). For North America, installations

must be per the U. S. National Electrical Code, NFPA

70, or the Canadian Electrical Code in order to maintain

Class I, Division 2 ratings. This may require using

connections or other adaptations in accordance with

the requirements of the authority having jurisdiction.

WARNING

: Explosion Hazard - Substitution of

components may impair suitability for Class I, Division

2 applications.

WARNING

: Explosion Hazard - When in hazardous

locations, turn power OFF before replacing or wiring

modules.

WARNING

: Explosion Hazard - Do NOT disconnect

equipment unless power has been switched OFF or

the area is known to be Non-Hazardous.