CM-ET Prostar User Manual

Page 9

If the stock diameter of the worn link is 0.010 inches

(0.254mm), or more, less than the stock diameter of the

unworn link, the chain must be replaced.

On the Double-reeved units, repeat this examination of the

chain that passes through the hook block.

Also check chain for stretch using a vernier caliper as

shown in Figure 6B. Select an unused, unstretched section

of chain (usually at the loose end) and measure and record

the length over 11 chain links (pitches). Measure and record

the same length on a worn section of chain. Obtain the

amount of stretch and wear by subtracting the measurement

of the unworn section from the measurement of the worn

section. Based upon ASME B30.16 2007.Select an unworn,

unstretched length of the chain (at the slack end for

example). Suspend the chain vertically under tension and,

using a caliper-type gauge, measure the outside length of

any convenient number of links approximately 12" to 24".

Measure the same number of links in the use sections and

calculate the percentage in increased length.

Replace if length of the used portion is more than 1 1/2%

longer than the unused portion of the chain. Based upon

ASME B30.16 2007.

Use only a “Knife-edge” caliper to eliminate possibility of

false reading by not measuring full pitch length.

Note that worn chain can be an indication of worn hoist

components. For this reason, the hoist’s chain guide, hook

block and liftwheel should be examined for wear and

replaced as necessary when replacing worn chain.

Also, these chains are specially heat treated and hardened

and should never be repaired.

IMPORTANT: Do not use replaced chain for other purposes

such as lifting or pulling. Load chain may break suddenly

without visual deformation. For this reason, cut replaced

chain into short lengths to prevent use after disposal.

Chain Lubrication

A small amount of lubricant will greatly increase the life of

load chain. Do not allow the chain to run dry.

Keep it clean and lubricate at regular intervals with

Lubriplate

®

Bar and Chain Oil 10-R (Fiske Bros. Refining Co.)

or equal lubricant. Normally, weekly lubrication and cleaning

is satisfactory, but under hot and dirty conditions, it may be

necessary to clean the chain at least once a day and

lubricate it several times between cleaning.

When lubricating the chain, apply sufficient lubricant to

obtain natural run-off and full coverage, especially in the

interlink area.

LUBRICATION

Refer to Exploded View and Parts List pages 15 through 19.

NOTE: To assure extra long life and top performance, be

sure to lubricate the various parts of the Prostar Hoist

using the lubricants specified below. If desired, these

lubricants may be purchased from the factory. Refer to

page 19 for information on ordering the lubricants.

Gears

• The Protector (620-111) should operate for the normal life of

the hoist without service. The device has been lubricated

and calibrated by the factory and should not be adjusted.

CAUTION: The Protector™ is to be used with “Century

Lubricants HB-11, #3” grease. Do not use any other

grease or the Protector will not operate properly and

parts could be damaged.

The gears and Protector are packed at assembly with

grease and should not need to be renewed unless the gears

have been removed from the housing and degreased.

CAUTION: Never degrease the Protector™ or attempt to

disassemble this device. Degreasing the Protector may

damage parts and using a device that has been degreased

may cause erratic, inconsistent operation. If the Protector

has been degreased, it must be replaced by a factory

calibrated device.

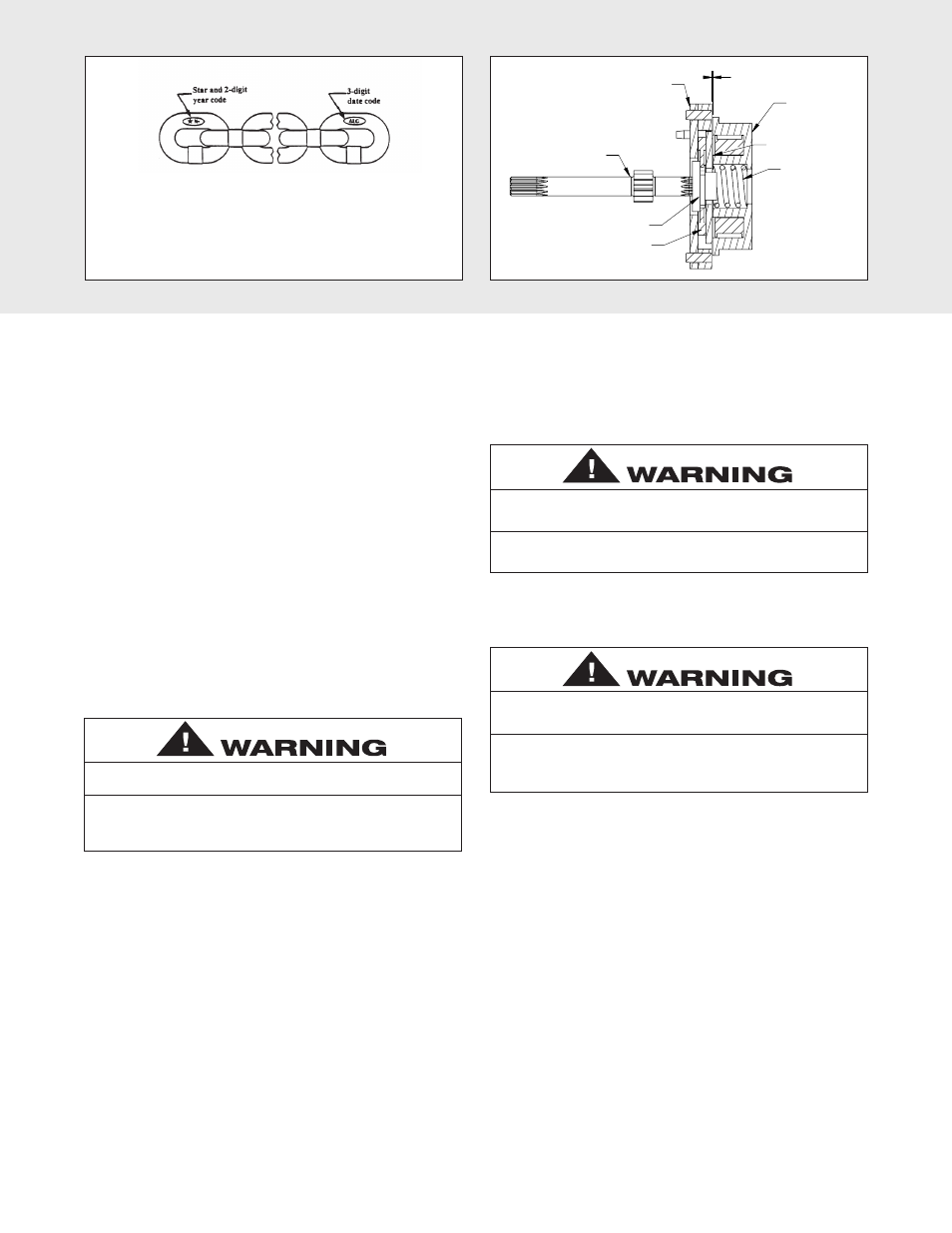

Figure 7A

Figure 7B

8

Use only Star (H) grade load chain and factory

replacement parts. Use of other chain and parts may

be dangerous and voids factory warranty.

Use of commercial or other manufactures’ chain and parts to

repair hoists may cause load loss.

TO AVOID INJURY:

Use only factory supplied replacement load chain and parts.

Chain and parts may look alike, but our chain and parts are made

of specific materials or processed to achieve specific properties.

Used motor oils contain known carcinogenic materials.

TO AVOID HEALTH PROBLEMS:

Never use used motor oils as a chain lubricant. Only use

Lubriplate

®

Bar and Chain Oil 10-R as a lubricant for the

load chain.

The lubricants used in and recommended for the Prostar Hoist

may contain hazardous materials that mandate specific handling

and disposal procedures.

TO AVOID CONTACT AND CONTAMINATION:

Handle and dispose of lubricants only as directed in applicable

material safety data sheets and in accordance with applicable

local, state and federal regulations.

Assembly-

Brake Driver

Includes Coil

Brake Spring

Brake Armature

Brake Base Plate

Brake Disc

Brake Field

First Pinion

Shaft

Brake Assembly

Gap