CM-ET Prostar User Manual

Page 10

9

If the gears are removed from the housing, wipe the excess

grease off the outside surfaces of the Protector with a soft

cloth and degrease the remaining gears and housings.

Upon reassembly, add 2 oz. of the above grease to gears

and housing. Also, coat the spline on the end of the first

pinion and shaft (620-131) with a Molydisulphide lubricant

such as Moly-Duolube 67 (Hercules Packing Co.).

Bearings

Rotor bearings (620-102 and 620-103) are pre-lubricated

and require no lubrication. Needle bearings (620-109, 620-

114, 620-115, 620-128 and 620-164) are packed at

assembly with grease and should not need to be

relubricated. However, if the housings (620-113 and 620-

107), liftwheel (620-127) or sheave wheel (620-162) have

been degreased, these bearings should be greased using

“Century Lubricants HB-11, #3” grease.

Seals

When reassembling the unit, wipe the inside surface of the

seals (620-108 and 620-130) with “Century Lubricants HB-

11, #3” grease.

Hook Block

If the hook blocks are disassembled for inspection

purposes, wipe the grease from the hook knob and the hook

knob cavities in the hook blocks. At reassembly, coat the

underside of the hook knob and the knob bearing surfaces

of cavities in the hook blocks with Molykote BR-2-S (Dow

Corning Corp.) grease or equivalent.

Chain Guide, Liftwheel and Sheave Wheel

• When the hoist is disassembled for inspection and/or

repair, the chain guide, stripper, sheave wheel (on double

chain unit) and liftwheel must be lubricated with

Lubriplate

®

Bar and Chain Oil 10-R (Fiske Bros. Refining

Co.) prior to reassembly. The lubricant must be applied in

sufficient quantity to obtain natural runoff and full coverage

of these parts.

Load Chain

Refer to page 7 for lubrication of the load chain.

Exterior Finish

The exterior surface of the hoist has a durable, scratch

resistant baked powder coating. Normally, the exterior

surfaces can be cleaned by wiping with a cloth. However, if

the finish is damaged, compatible touch-up paint can be

purchased from the factory. Refer to page 19 for information

on ordering the paint.

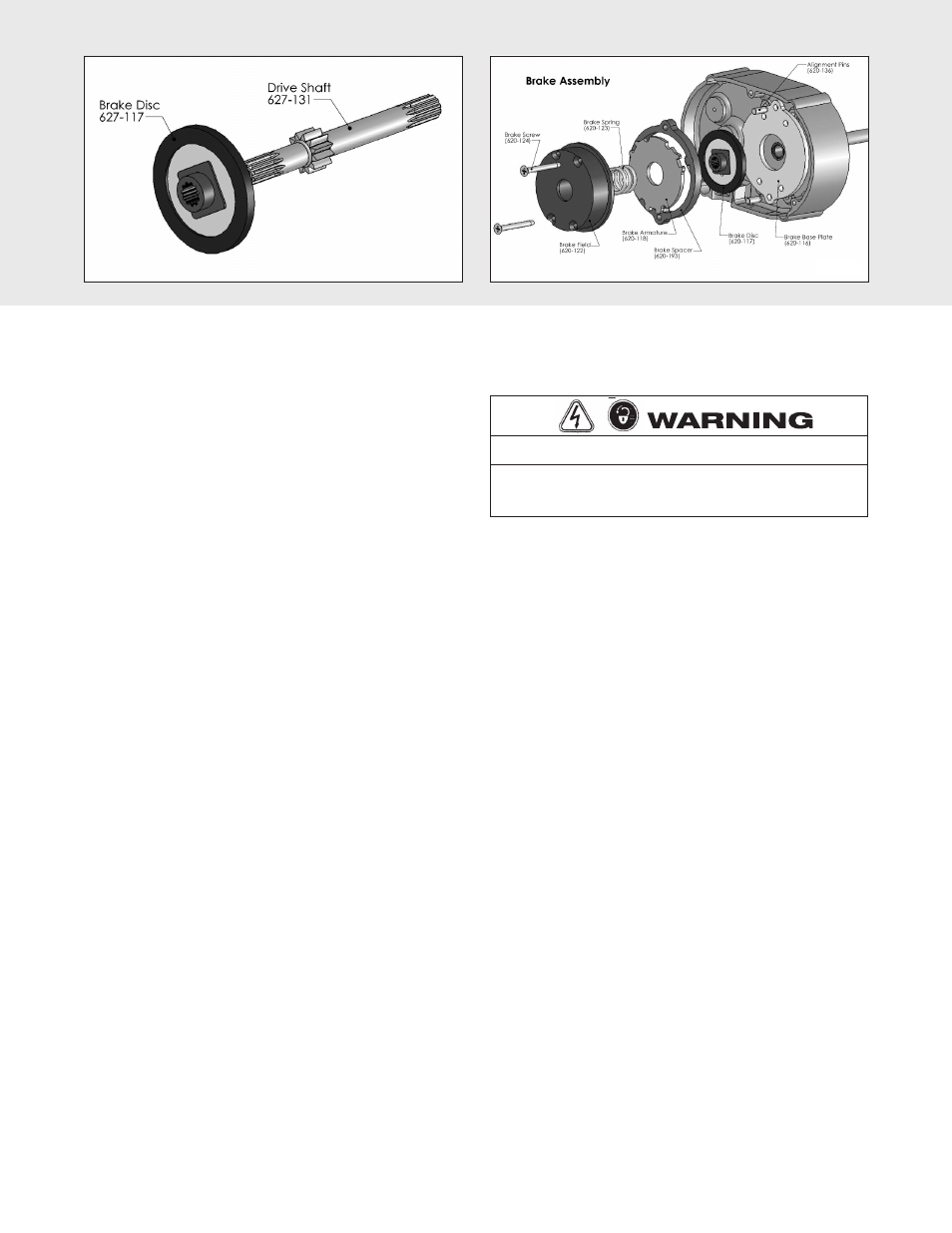

ELECTRIC BRAKE

The brake is non-adjustable with a nominal .004 inch (0.102

mm) air gap and the brake disc must be replaced when the

air gap reaches .012 inch (0.305 mm). The brake spacer

should be no more than .012 inch (0.305 mm) thicker than

the combined thickness of the brake disc and armature

plate. Refer to Figure 7B, page 8.

To inspect the brake gap, disconnect the hoist from power

and remove brake end cover (620-132).

1. Refer to Figure 8B and disassemble the brake. Depress

and hold the field assembly (620-122) while removing the

four brake screws (620-124). The field assembly is under

spring pressure and will spring-out if not held. Examine

the base plate (620-116), brake disc (620-117) and

armature (620-118) for excessive wear, scoring or

warpage. Make sure the brake disc is not glazed, the coil

firmly fixed in the field (620-122) and the brake spring

(620-123) is not damaged. Worn, scored, warped, glazed

or damaged parts should be replaced before preceding.

2. Refer to Figure 8B and assemble the brake. Depress

and hold the field assembly (620-122) while installing the

four brake screws through the brake parts and mount the

brake on the gear housing (620-113). Tighten the four

brake screws (620-124) to 25 in.lb. (2.8 NM).

PROTECTOR™

The Protector should operate for the normal life of the hoist

without service. The device has been lubricated and

calibrated and it should not be adjusted. If the Protector is

not operating properly (see testing on page 14), it must be

replaced with a properly calibrated unit from the factory.

PREVENTATIVE MAINTENANCE

A preventative maintenance program should be established

to prolong the useful life of the hoist and maintain its reliability

and continued safe use. The program should include the

periodic and frequent inspections with particular attention

being paid to the lubrication of the various components using

the recommended lubricants (see page 19).

Failure to follow proper lockout/tagout procedures may present the

danger of electrical shock.

TO AVOID INJURY:

Disconnect power and lockout/tagout disconnecting means before

removing cover or servicing this equipment.

Figure 8A

Figure 8B