Operating instructions – CM-ET Prostar User Manual

Page 6

5

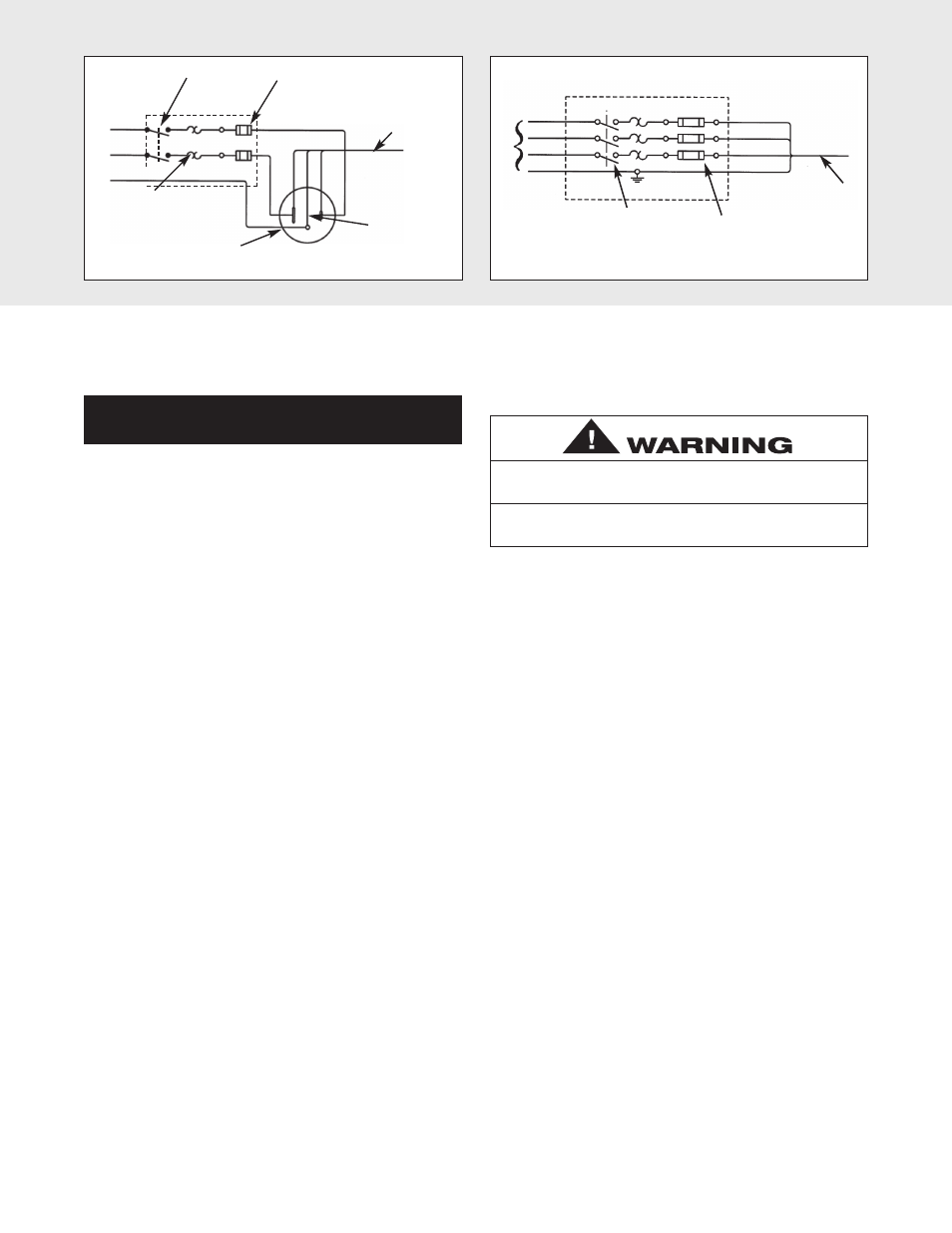

Hoist Power

Cord

Green-Yellow

* Manual

Disconnect

Switch

Black

White

Ground

* Slow Blow Fuses

or Inverse Time

Circuit Breakers

* Thermal

Overload

Relay

*Receptacle Rated for 15 Amps Minimum (220-1-50 units do not

include Power Cord Plug). Wire Blue and Brown Wires to Fuses or

Circuit Breakers and Green-Yellow Wire to Ground.

Brown

Blue

S

Siin

ng

glle

e P

Ph

ha

as

se

e S

Sy

ys

st

te

em

ms

s

Hoist Power Cord

* Slow Blow Fuses

or Inverse Time

Circuit Breakers

* Must be per National Electrical

Code and These Devices are to be

Supplied by the User.

* Manual Disconnect

Switch

Black

Grey

Brown

Green-Yellow

T

Th

hr

re

ee

e P

Ph

ha

as

se

e S

Sy

ys

st

te

em

ms

s

L1

L2

L3

Ground

In

c

o

m

in

g

P

o

w

e

r

Figure 4A

Figure 4B

CHAIN CONTAINER

If the chain container is to be used, attach it to the hoist per

the instructions provided.

The hoist is equipped with a Protector™ that is designed to

allow the first gear to slip on an excessive overload. An

overload is indicated when the hoist speed slows down, it

raises the load in a jerky manner or it will not lift the load at

all. Also, some clutching noise may be heard if the hoist is

loaded beyond rated capacity. Should this occur, immediately

release the UP button to stop the operation of the hoist. At

this point, the load should be reduced to the rated capacity

or the hoist should be replaced with one of the proper

capacity. When the excessive load is removed, normal hoist

operation is automatically restored.

CAUTION: The Protector™ is susceptible to overheating

and wear when slipped for extended periods. Under no

circumstance should the Protector be allowed to slip for

more than a few seconds.

Due to the above, the hoist is not recommended for use in

any application where there is a possibility of adding to an

already suspended load to the point of overload. This

includes dumbwaiter installations, containers that are loaded

in mid-air, etc. Also, if the hoist is used at unusual extremes

of ambient temperatures, above 150º F (65ºC). or below 15ºF

(-9ºC)., changes in lubricant properties may permit the hoist

to raise larger loads than under normal operating conditions

and present possibility of damage or injury.

On units without contactor (hoists with orange control

station) it is necessary to stop the hoist before changing

direction. Therefore, when lowering a load, the push

button in the control station must be released

momentarily before the UP button is depressed to raise

the load. If this is not done, the hoist will continue to

operate in the down direction while the UP push button

is depressed, and it will continue to lower the load until

the control push button is released. As a result, the

direction must not be reversed quickly (plug reversed).

There are no electrical switches to stop the operation of the

hoist at the upper and lower limits of lift. As a result, it is

necessary to release the push button in the control station to

stop the hoist before the hook block or chain stop contacts

the bottom of the hoist frame. If the hook block or chain stop

contacts the hoist frame, the Protector will function to stop

the hoisting or lowering operation and protect the hoist

components from damage. However, continued, prolonged

or repeated slipping of the Protector will damage the

Protector and cause overheating of the internal hoist

components.

Hoist operation is controlled by depressing the control

station push buttons (Refer to Figure 5A, pg 6). Depressing

the UP push button will move the load hook toward the hoist

head; depressing the DOWN push button will move the load

hook away from the hoist head.

The UP and DOWN buttons are momentary type and the

hoist will operate in the selected direction as long as the

button is held in the depressed position. Release the push

button and the hoist will stop.

It is preferred that the load always be tied off with auxiliary

chains or cables before access to the area beneath the load

is permitted. As an alternative, the system may be designed

such that malfunction or failure of one hoist’s load bearing

components does not cause load loss and/or overloading of

any other hoists in the system. Note that in such a system,

hoist performance and function must be monitored visually

or with the use of load cells. Check the supporting structure

to which the load hook is to be attached. Make sure the

attachment point as well as the structure have sufficient

strength to withstand several times the load imposed. If in

doubt, consult a registered engineer and local building

codes.

Allowing the hook block to run into the hoist when raising a load or

allowing the chain stop to run into the hoist when lowering a load

may break the chain and allow the load to drop.

TO AVOID INJURY:

Do not allow the hook block or the chain stop to contact the hoist

frame.

OPERATING INSTRUCTIONS