Maintenance – CM-ET Prostar User Manual

Page 7

13. Do not allow the load to swing or twist while hoisting.

14. Never operate the hoist when flammable materials or

vapors are present. Electrical devices produce arcs or

sparks that can cause a fire or explosion.

15. STAY ALERT! Watch what you are doing and use

common sense. Do not use the hoist when you are

tired, distracted or under the influence of drugs, alcohol

or medication causing diminished control.

INSPECTION

To maintain continuous and satisfactory operation, a regular

inspection procedure must be initiated so that worn or

damaged parts can be replaced before they become

unsafe. The intervals of inspection must be determined by

the individual application and are based upon the type of

service to which the hoist will be subjected. The inspection

of hoists is divided into two general classifications

designated as “frequent” and “periodic”.

6

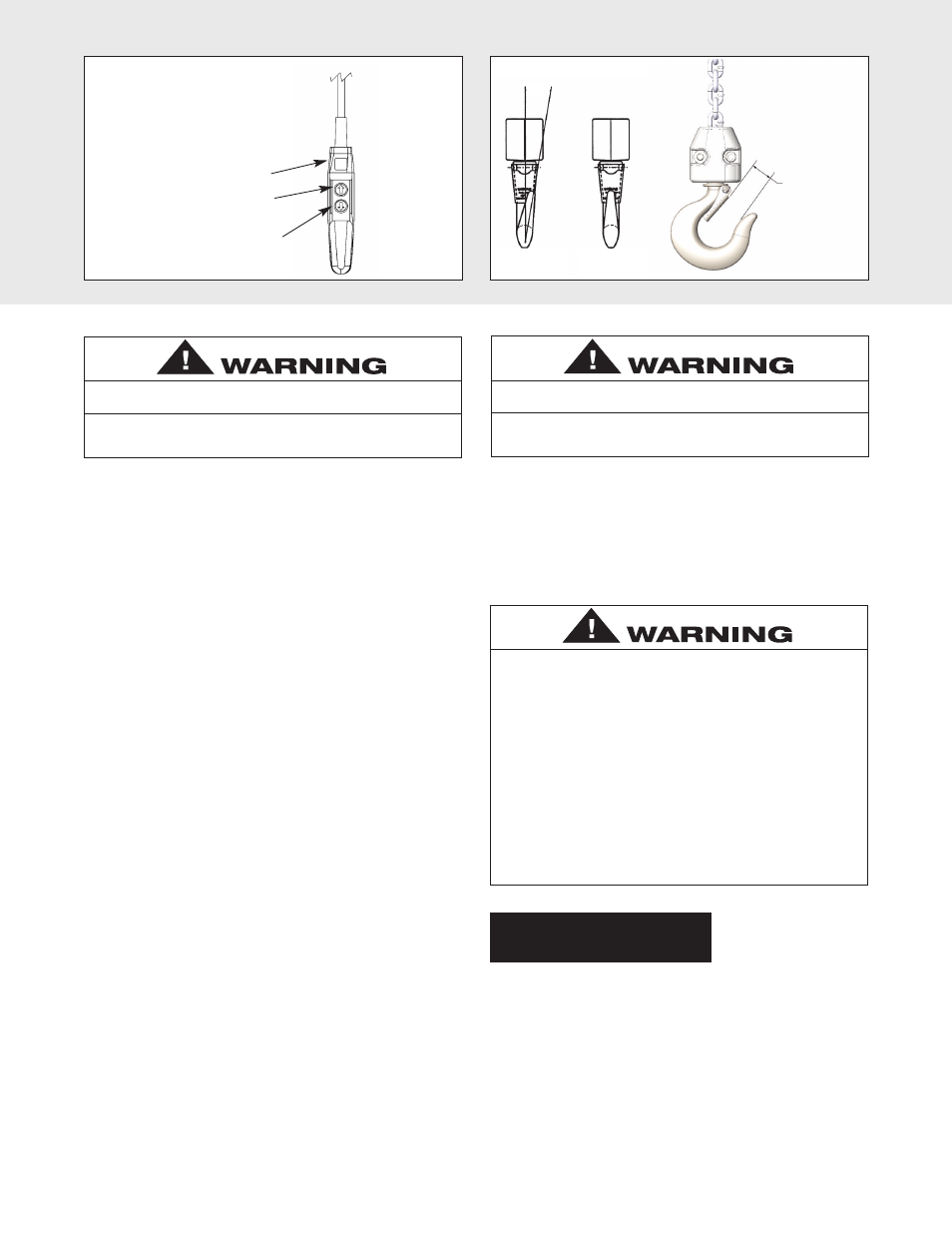

1. When preparing to lift a load, be sure that the attach-

ments to the load hook are firmly seated in hook saddle.

Avoid off center loading of any kind, especially loading

on the point of the hook.

2. When lifting, raise the load only enough to clear the floor

or support and check to be sure that the attachments to

the hook and load are firmly seated. Continue lift only

after you are assured the load is free of all obstructions.

3. Do not load the hoist beyond the rated capacity shown

on the brake end cover. Overloading can cause

immediate failure of some load-carrying part or create a

defect causing subsequent failure at less than rated

capacity. When in doubt, use the next larger capacity of

hoist.

4. Do not use this or any other overhead materials

handling equipment for lifting persons or allow people

on unsecured load.

5. Stand clear of all loads and avoid moving a load over

heads of other personnel. Warn personnel of your

intention to move a load in their area. Do not leave

unsecured load over people.

6. Do not leave the load suspended in the air unattended.

7. Permit only qualified personnel to operate unit.

8. Do not wrap the load chain around the supporting

structure and hook onto itself as a choker chain.

Doing this will result in:

a. The loss of the swivel effect of the load hook which

could mean twisted chain and a jammed liftwheel.

b. The chain could be damaged at the load hook.

9. After positioning, secure load by using auxiliary cables

and/or chains.

10. On the Double-reeved hoists, check for twists in the

load chain. A twist can occur if the lower block has

been capsized between the strands of chain. Reverse

the capsize to remove twist.

11. Do not allow a load to bear against the hook latch. The

latch is to help maintain the hook in position while the

chain is slack before taking up the slack chain.

12. Take up a slack load chain carefully and start load

easily to avoid shock and jerking of hoist chain. If there

is any evidence of overloading, immediately lower the

load and remove the excess load.

Attaching the load hook to an inadequate support may allow the

hoist and load to fall and cause injury and/or property damage.

TO AVOID INJURY:

Make sure the structure and the load hook attachment point have

sufficient strength to hold several times the hoist and rated load.

Allowing a load to bear against the hook latch and/or hook tip can

result in loss of load.

TO AVOID INJURY:

Do not allow a load to bear against the hook latch and/or hook tip.

Apply load to hook bowl or saddle only.

Figure 5A

Figure 5B

T

TO

O

A

AV

VO

OI

ID

D

I

IN

NJ

JU

UR

RY

Y:

:

--D

DO

O N

NO

OTT

Lift more than rated load.

--D

DO

O N

NO

OTT

Operate with twisted, kinked or damaged chain.

--D

DO

O N

NO

OTT

Operate damaged or malfunctioning hoist.

--D

DO

O N

NO

OTT

Lift people, loads over people, allow people on

unsecured load or leave unsecured load over people.

--D

DO

O N

NO

OTT

Operate hoist when load hook is not centered over

hoist.

--D

DO

O N

NO

OTT

Permit load hook block to contact hoist frame or chain

container.

--D

DO

O

Replace damaged or malfunctioning hook latch.

--D

DO

O

Keep load chain well oiled.

Twisted

Do Not Use

10°

MAX.

Black Station

for Hoists

With

Contactor

Control Station

Depress to Move

Load Hook Towards

Hoist Head

Depress to Move

Load Hook Away

From Hoist Head

MAINTENANCE

Normal

Ok To Use

Replace

Hook When

Opening is

Greater

Than 1-1/8”

(28.5mm)