CM-ET Prostar User Manual

Page 5

4

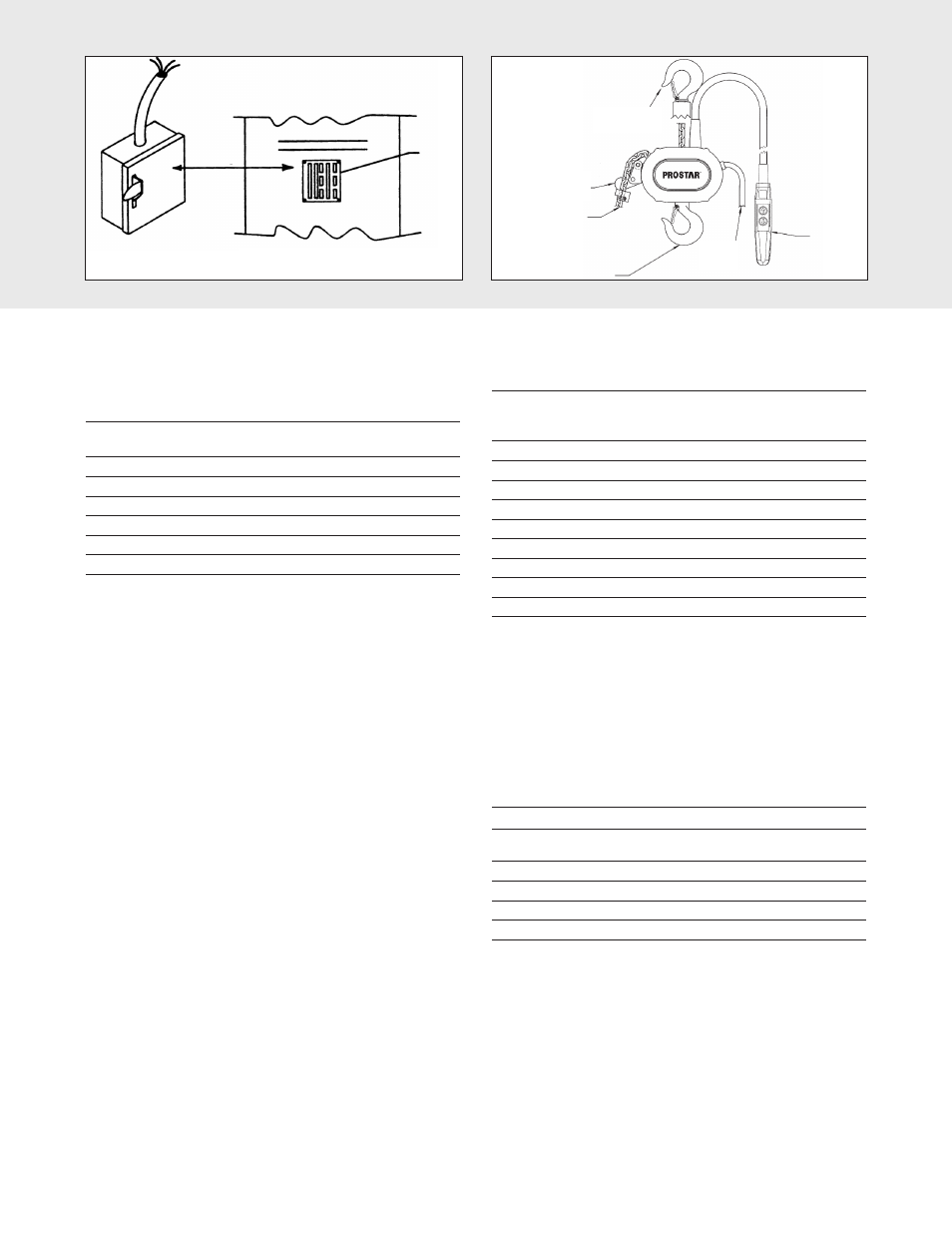

Figure 3A

Figure 3B

Power supply

Same

Making sure the hoist will operate on

the power supply system

Name

plate

Load Hook

Chain

Stop

Control

Station

Mounting Hook

Power

Cord

NOTE: IN THIS MANUAL, NOMINAL VOLTAGES ARE

USED WHEN REFERRING TO POWER SUPPLY

SYSTEMS. HOWEVER, WITH NO MODIFICATION, THE

PROSTAR HOIST WILL OPERATE ON A RANGE OF

VOLTAGES AS INDICATED BELOW:

NOMINAL

VOLTAGE

HERTZ

VOLTAGE

RANGE

230

208-240

60

460

440-480

60

220

200-240

50

380

365-395

50

415

400-430

50

575

550-600

60

Three Phase Hoists

Since the motor in a three phase hoist can rotate in either

direction, depending on the manner in which it is connected

to the power supply, the direction of hook movement must

be checked during the original installation and each time

hoist is moved to a new location as follows:

1. Move the manual disconnect switch handle to the “OFF”

position.

2. Connect the BROWN, GREY AND BLACK wires of hoist

power cord to load side of disconnect switch. Connect the

GREEN-YELLOW wire of hoist power cord to power

supply ground.

3. Move the manual disconnect switch handle to the “ON”

position.

4. Depress the (up) control. If the hook moves in the up

direction, the hoist is ready for operation. If the hook

lowers, move the disconnect switch handle to the “OFF”

position and interchange the BLACK and BROWN leads

at the disconnect switch. Move the disconnect switch

handle to the “ON” position and the hoist is now ready for

operation.

Checking for Adequate Voltage at Hoist

The hoist must be supplied with adequate electrical power

for proper operation and to reduce problems that may result

from insufficient power (low voltage). These include:

• Noisy hoist operation due to brake and/or contactor

chatter.

• Heating of the hoist motor and other internal components

as well as heating of wires and connectors in the circuit

feeding the hoist.

• Failure of the hoist to lift the load due to motor stalling.

• Blowing fuses or tripping circuit breakers.

• Dimming of lights or slowing of motors connected to the

same circuit.

For proper operation and to avoid these low voltage

problems, voltage (measured at end of the power cord while

lifting rated load) should be as the following chart indicates.

NOMINAL

MINIMUM

* MIN. VOLTAGE

POWER

OPERATING

AT INSTANT

SUPPLY

VOLTAGE

OF START

115-1-50/60

108

103

220-1-50

198

182

208-3-60

187

172

220-3-50

198

182

230-3-60

207

190

380-3-50

365

336

415-3-50

399

367

460-3-60

414

380

575-3-60

518

506

*The drop in voltage upon energizing the hoist should

not be below the value listed.

Low voltage can also be caused by using an undersize

extension cord to supply power to the hoist. The following

charts should be used to determine the size wires in the

extension cord in order to minimize the voltage drop

between the power source and the hoist.

115-1-50/60 units with contactor, 220-1-50 units and three

phase units (hoists with black control station)

MAXIMUM LENGTH OF EXTENSION CORD

Wire Size

Single

Three

Phase Hoist

Phase Hoist

#16 A.W.G.

135 feet(40 M)

245 feet(73 M)

#14 A.W.G.

220 feet(66 M)

395 feet(120 M)

#12 A.W.G.

354 feet(107 M)

630 feet(192 M)

After the hoist is suspended from its support and you have

made sure the power supply complies with the above, the

hoist is ready for operation.

On the Double units, cut and discard the ties used to hold

the two strands of chain together. With no load on the lower

hook, depress the UP button in the control station and raise

the lower hook until it is about 2 feet below the bottom of the

hoist. Check both strands of chains for twists. Twists occur

if the lower hook block has been capsized between the

strands of chain during packing, shipment and/or handling.

Reverse the capsize to remove twists.

Loose

End of

Chain