Installation – CM-ET Prostar User Manual

Page 4

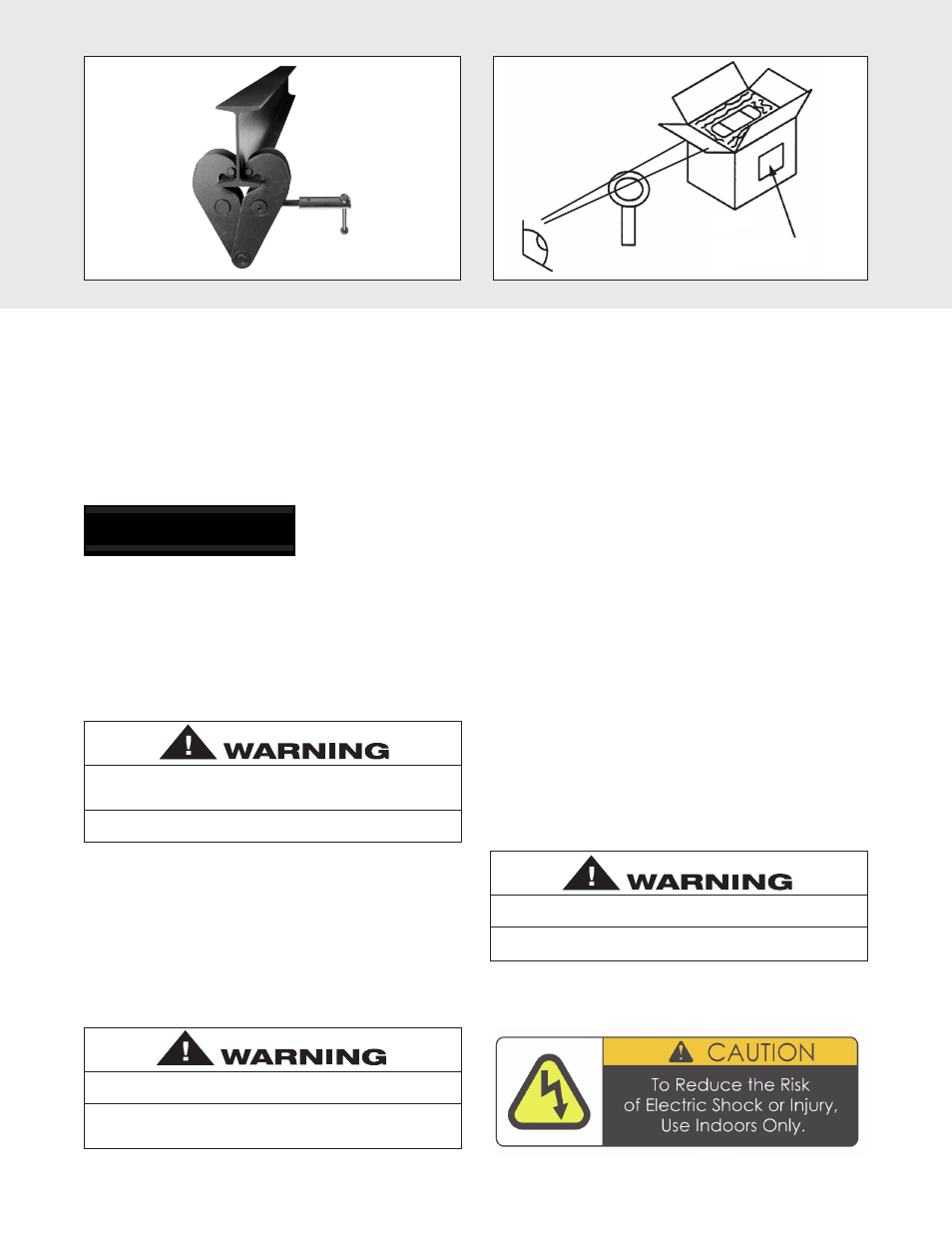

BC Series Beam Clamps

The beam clamps are ideal as anchors for rigging

applications (Figure 2A). The BC series clamps can be

adjusted to fit a wide range of beam sizes. The lightweight

and compact design makes the beam clamps ideal for

repeated set-ups and tear-downs.

Entertainment Rigging Products

Refer to sales Bulletin No. EPD-10B for additional rigging

products that can be used in the entertainment industry.

UNPACKING

After opening the carton (Figure 2B) , carefully inspect the

hoist frame, cords, hooks, chain and control station for

damage that may have occurred during shipment. If there is

damage, refer to the packing slip envelope.

Make sure that the power supply (Figure 3A) to which the

hoist is to be connected is the same as that shown on the

identification plate located on bottom of hoist.

MOUNTING THE HOIST

Attach the hoist to the truss/structure to be lifted using the

mounting hook (Figure 3B) . Be sure that the attachment

point is held in the lowermost part of the hook arc and the

latch is tightly against the hook tip. Also, the attachment

point must have sufficient strength to withstand several times

the load imposed. If in doubt, consult a registered engineer

and local building codes.

3

Operating a unit with obvious external damage may cause load to

drop and that may result in personal injury and/or property

damage.

TO AVOID INJURY:

Carefully check unit for external damage prior to installation.

Figure 2A

Figure 2B

Claim Procedure

POWER SUPPLY SYSTEM

(Refer to Figure 4A or 4B on page 5). To insure proper

operation, to avoid damage to hoist and electrical system

and to reduce the risk of electric shock or fire, the branch

circuit supplying power to the hoist must:

1. Have ample capacity to prevent excessive voltage drop

during starting and operation (refer to “Checking for

Adequate Voltage at Hoist” on page 4). When determining

the size of branch circuit components and conductors,

special consideration should be given to the starting

current-amps (approximately three times that shown on

the hoist identification plate) and the length of the

conductors. As a minimum, the system should be rated for

15 amps and it should have #16 AWG, or larger, wiring.

2. Be in accordance with the National Electrical Code

(ANSI/NFPA-70) and applicable National, State and Local

Codes.

3. Effectively ground the hoist in accordance with National

Electrical Code and other applicable codes. Proper

grounding provides a path of least resistance for electric

current to reduce the risk of electric shock. The power

cord of the hoist includes a green-yellow wire for

grounding the hoist to the external power supply system.

Be sure that the receptacle opening that receives the

longest prong is properly grounded. If grounding is to be

through the trolley trackwheels, each section of the

runway must be grounded to the building ground system

using metal to metal connections.

4. Include slow blow type fuses or inverse trip time circuit

breakers to permit the hoist to start and accelerate load.

5. Include a disconnecting means capable of being locked

in the “open” position.

An inadequate attachment point may allow the hoist and load to

fall and cause injury and/or property damage.

TO AVOID INJURY:

Make sure the attachment point has sufficient strength to hold

several times the hoist and its rated load.

Failure to properly ground the hoist presents the danger of electric

shock.

TO AVOID INJURY:

Permanently ground the hoist as instructed in this manual.

INSTALLATION