CM-ET Prostar User Manual

Page 8

7

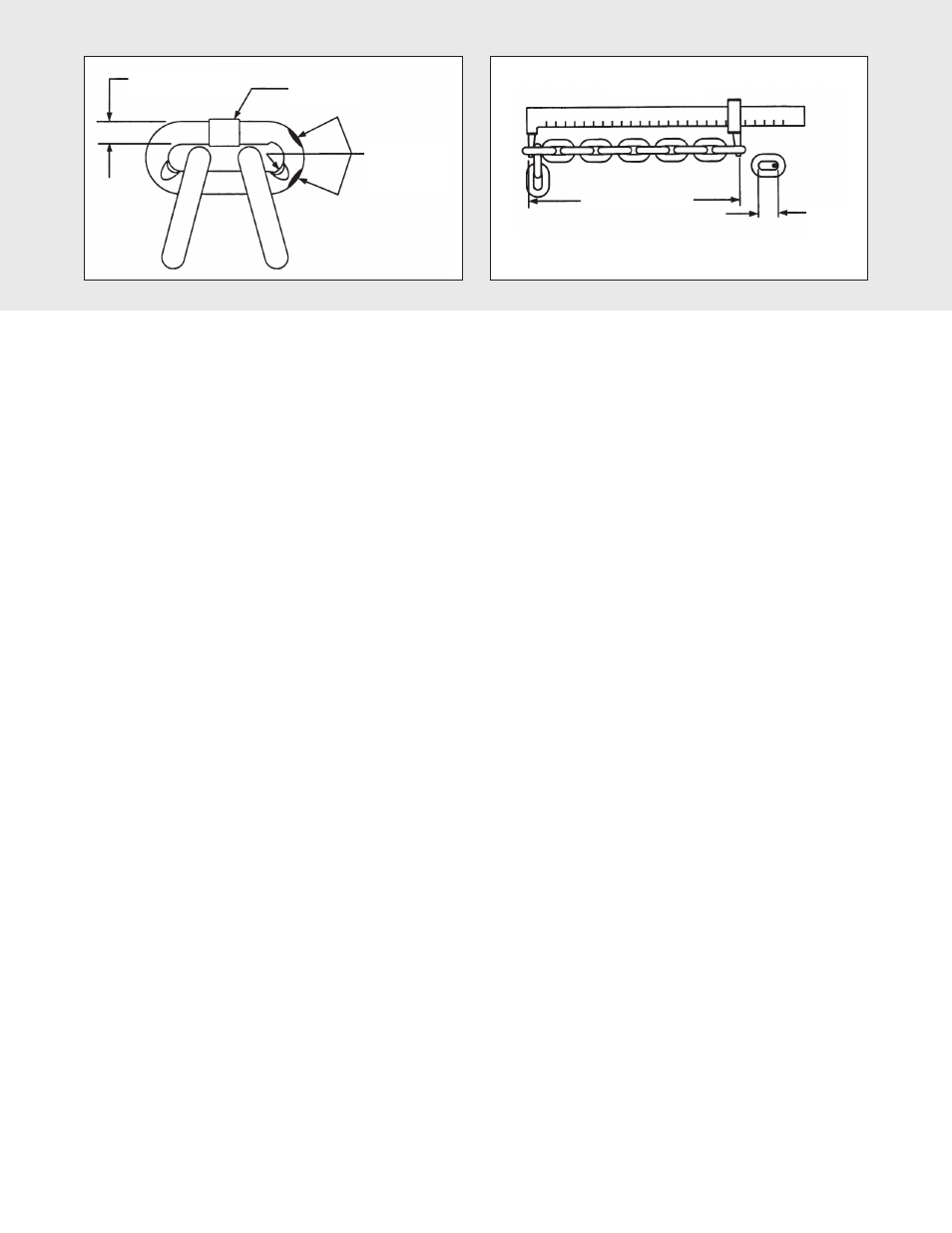

Figure 6A

Figure 6B

Frequent Inspections

These inspections are usually visual examinations by the

operator or other designated personnel. Frequent

inspections are to be performed daily or monthly and shall

include the following items:

a. Operate the hoist, with no load, and check for visual signs

or abnormal noises which could indicate a potential

problem - daily.

b.Brake for evidence of slippage - daily.

c. Chain for lubricant, wear, damaged links or foreign

material - daily (see below).

d.Hooks for damage, cracks, twist, latch engagement and

latch operation - daily (see below).

Any deficiencies must be corrected before the hoist is

returned to service.

Periodic Inspections

There are visual inspections by an appointed person who

records apparent external conditions to provide a basis for

continuing evaluation. Periodic inspections are to be

performed semi-annually and they should include the

following:

a. All items listed under frequent inspections.

b.External evidence of loose screws.

c. External evidence of worn, corroded, cracked or distorted

hook block, gears, bearings, chain stop and hook retainer.

d.External evidence of damage or excessive wear of the

liftwheel or sheave (double-reeved unit). Widening and

deepening of pockets may cause chain to lift-up in the

pockets and cause binding between liftwheel and chain

guide or between lower sheave and hook block. Check

chain guide for wear or burring where the chain enters the

hoist. Severely worn or damaged parts should be

replaced.

e. External evidence of excessive wear of brake parts - see

page 9.

f. Check the control station push buttons to make sure they

operate freely and spring back when released.

g.Check power cord, control cord and control station for

damaged insulation.

h. Check for pitting and any deterioration of contactor

contacts (hoists with black control station).

i. Check the chain pin or dead end pin and chain stop for

wear and cracks.

j. Check for lubricant leaks at gasket between main frame

and gear housing. Tighten gear housing screws to stop

leak. If leak persists, replace gasket.

k. Inspect splines on first pinion shaft and motor coupling for

signs of wear or deterioration. Replace splined parts if

worn or damaged.

NOTE: To perform some of the periodic inspections, it is

necessary to partially disassemble the hoist. Refer to

Disassembly - Assembly starting on page 13.

Any deficiencies noted must be corrected before the hoist is

returned to service. Also, the external conditions may show

the need for more detailed inspection which, in turn, may

require the use of nondestructive-type testing.

Any parts that are deemed unserviceable are to be replaced

with new parts before the unit is returned to service. It is very

important that the unserviceable parts be destroyed to

prevent possible future use as a repair item and properly

disposed of.

Hook Inspection

Hooks damaged from chemicals, deformations or cracks or

that have more than a 10° twist from the plane of the unbent

hook or excessive opening must be replaced.

Any hook that is twisted or has excessive throat opening

indicates abuse or overloading of the unit. Other load-

sustaining components of the hoist should be inspected for

damage.

On latch type hooks, check to make sure that the latch is not

damaged or bent and that it operates properly with sufficient

spring pressure to keep the latch tightly against the tip of the

hook and allow the latch to spring back to the tip when

released. If the latch does not operate properly. It should be

replaced. See Figure 5B, Pg. 6 to determine when the hook

must be replaced.

LOAD CHAIN

Chain should feed smoothly into and away from the hoist or

hook block Double-reeved. If chain binds, jumps or is noisy,

first clean and lubricate it (see below). If trouble persists,

inspect chain and mating parts for wear, distortion or

other damage.

Chain Inspection

First clean chain with a non-caustic/non-acid type solvent

and make a link by link inspection for nicks, gouges, twisted

links, weld spatter, corrosion pits, striations (minute parallel

lines), cracks in weld areas, wear and stretching. Chain with

any one of these defects must be replaced.

Slack the portion of the chain that normally passes over the

liftwheel. Examine the interlink area for the point of maximum

wear (polishing see Figure 6A). Measure and record the

stock diameter at this point of the link. Then measure stock

diameter in the same area on a link that does not pass over

the liftwheel (use the link adjacent to the loose end link for

this purpose). Compare these two measurements.

Weld

.157 Inches

(4 mm) Diameter

Wear in These

Areas

Vernier Caliper

Measure 11 Pitches

One

Pitch