Specifications – CM-ET Prostar User Manual

Page 3

2

REPAIR/REPLACEMENT POLICY

All Prostar Electric Chain Hoists are inspected and

performance tested prior to shipment. If any properly

maintained hoist develops a performance problem, due to a

material or workmanship defect, as verified by the factory,

repair or replacement of the unit will be made to the original

purchaser without charge. This repair/replacement policy

applies only to Prostar Hoists installed, maintained and

operated as outlined in this manual, and specifically

excludes hoists subject to normal wear, abuse, improper

installation, improper or inadequate maintenance, hostile

environmental effects and unauthorized

repairs/modifications.

We reserve the right to change materials or design if, in our

opinion, such changes will improve our product. Abuse,

repair by an unauthorized person, or use of non-factory

replacement parts voids the guarantee and could lead to

dangerous operation. All Prostar Electric Chain Hoists are

backed with a lifetime warranty. Refer to the back cover for

details and limitations.

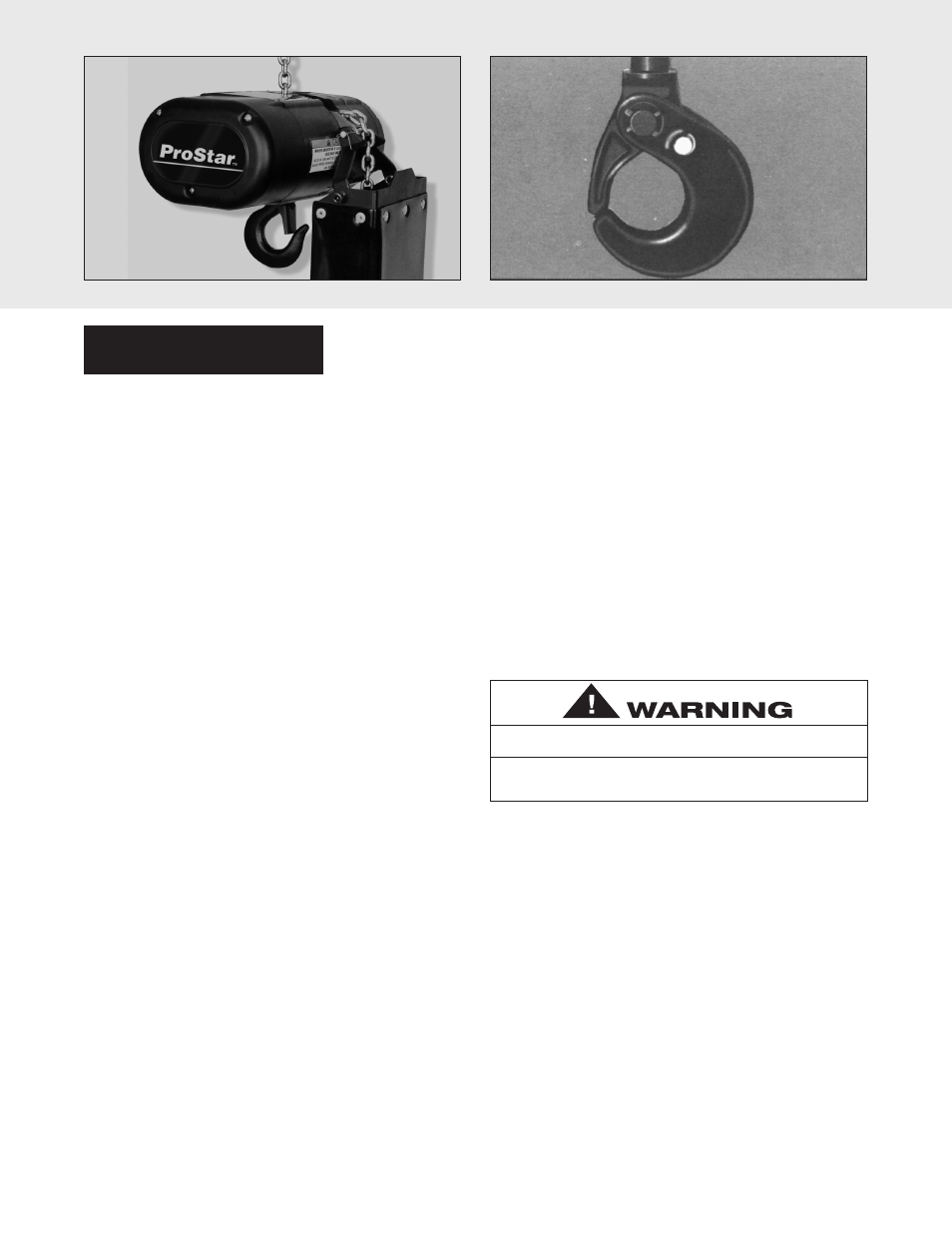

ACCESSORIES

Chain Container

This accessory item (Figure 1A) is used to hold the slack

chain and it is supplied with mounting hardware and

instructions. Chain containers are recommended for those

applications where slack chain will interfere with the load or

drag on the floor as may more often be the case with the

Double-reeved units. Chain containers are shipped

separately and can be furnished for units already in service.

Latchlok

®

Hooks

Latchlok Hooks (Figure 1B) are available to replace the

standard lower latch type hooks. The unique design of the

Latchlok Hook assures that it will stay locked until the

operator releases it by depressing the release button. It will

not open accidentally–even if the load chain goes slack.

Once opened, it can be shut with one hand or the weight of

the load when it is lifted. Latchlok Hooks can be supplied

with the hoist or they can be provided in kit form for hoists

already in service.

The Prostar Electric Chain Hoist is a highly versatile

materials handling device that can be used to lift loads that

are within its rated load capacity. It is available in six load

ratings.

Standard features of the Prostar Electric Chain Hoist include:

• Alloy steel, oblique lay liftwheel that provides constant

chain speed and reduces chain wear.

• Hoistaloy

®

load chain for long and dependable service.

• Grease lubricated, hardened spur gears provide smooth

and quiet operation.

• Thermally protected, hoist duty motor.

• Forged steel upper and lower hooks with latch.

• Protector™ that prevents lifting dangerous overloads.

• D.C. disc type motor brake plus regenerative braking.

• Standard Less Chain Unit. Longer lifts can be supplied on

a per order basis.

• 3 foot (.9 M) power cord with provisions for grounding is

standard on 115-50/60, 220-1-50 and three phase units.

• 3 foot (.9M) is standard for all control cords. Longer cords

can be provided on a per order basis.

• Lightweight die cast aluminum frames and covers.

• Ball or needle bearings at all rotating points.

• Compact, yet rugged, design provides minimum

headroom and long, trouble-free service.

• 6 fpm (1.8 m/min) lift speed available on 1000 lbs (453 kg)

units.

• 8 fpm (2.4 m/min) lift speed available on 500-600-1000 lbs

(226, 272 and 453 kg) units.

• 12 fpm (3.6 m/min) lift speeds available on 500-600-

1000 lbs (226, 272 and 453 kg) units.

• 16 fpm (4.9 m/min) lift speeds available on 250-300-

500 lbs (113, 136 and 226 kg) units.

• 20 fpm (6.1 m/min) lift speeds available on 500-600 lbs

(226 and 272 kg) units.

• 24 fpm (7.3 m/min) lift speeds available on 250-300-

500 lbs (113, 136 and 226 kg) units.

• 40 fpm (12.2 m/min) lift speeds available on 250-300 lbs

(113 and 136 kg) units.

• 220-1-50, 380 to 460-3-50/60, 220 to 240-3-50/60 and

575-3-60 units available. Lift speeds are based on 60

hertz power supply. For 50 hertz power supply lift speeds

will be 5/6 of those indicated.

• 13.3fpm (4.0m/min) lift speed available

on 550lbs (250Kg) units.

• UL and cUL listed.

• Lifetime Warranty.

Figure 1A

Figure 1B

Alterations or modification of hoist and use of non-factory repair

parts can lead to dangerous operation and injury.

TO AVOID INJURY:

• Do not alter or modify equipment.

• Do use only factory replacement parts.

SPECIFICATIONS