4 sample tubes installation, Installation 4.4.4 sample tubes installation – Hach-Lange POLYMETRON 9245 User Manual User Manual

Page 44

42

Installation

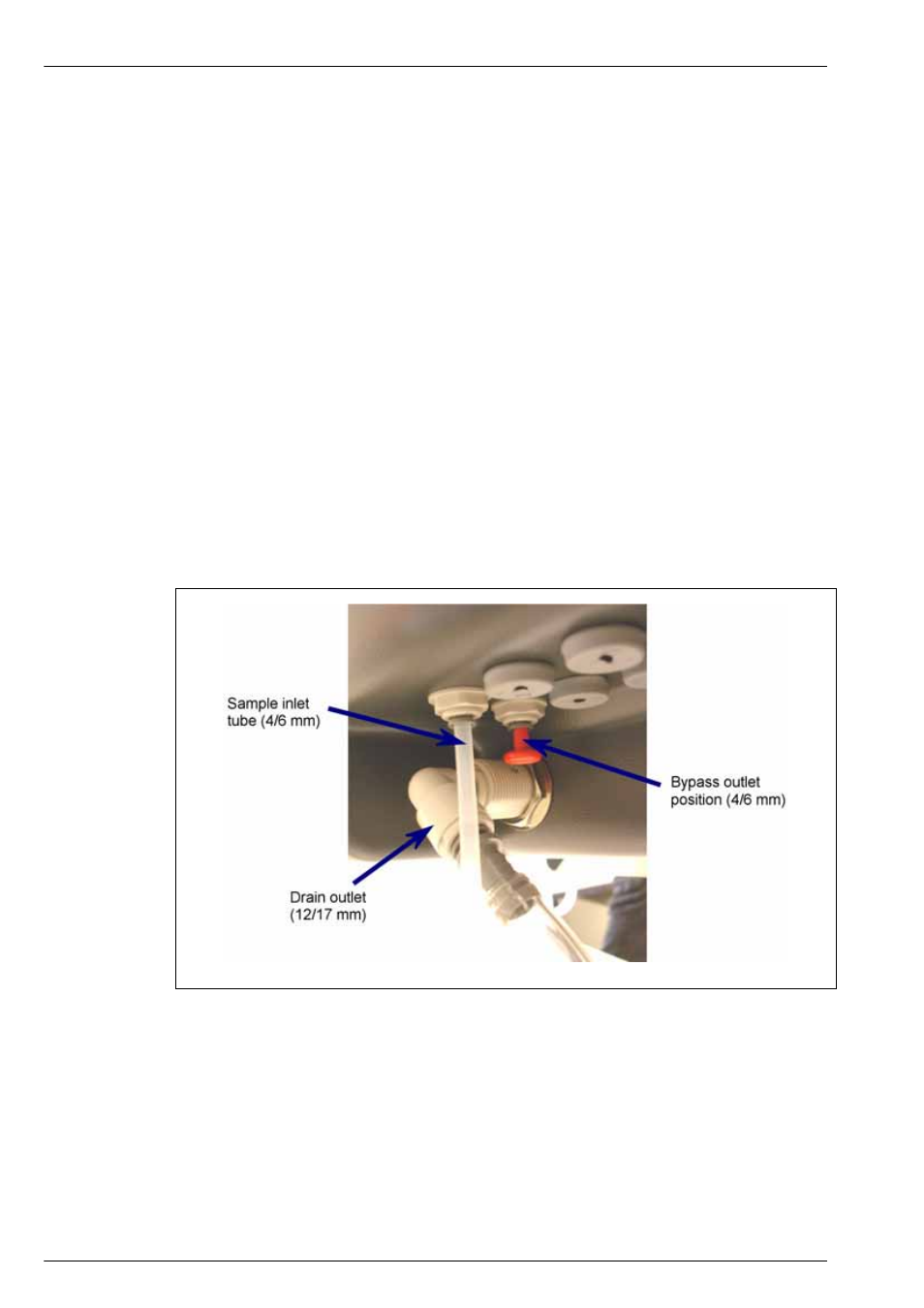

4.4.4 Sample tubes installation

•

Sample inlet connections

- 6 mm (or ¼'') in polyethylene or PTFE or FEP. If particulate

matter is present in the sample, pre-filtration is necessary. A filter should be inserted in the

sample line. One is available as an option. Use new pipes for all connections during

installation.

•

Flow rate

- 6 to 9 L/hour

•

Pressure

- 0.2 to 6 bars (8 to 100 psig)

•

Sample acidity

- Sample acidity should not be more than 300 ppm CaCO

3

•

Temperature

- Temperature must be between 5 to 45 °C

Note:

For continuous monitoring of sample with a temperature between 5-10°C it is recommended that the

installation should include a static heat-exchanger system (see

Accessories - Options - Maintenance kits on

for a list of part numbers).

At this stage of the installation, make sure that the flow valve is closed.

Connect the pipes by inserting them into the quick release connections found under the

sampling block.

Be sure that the sample line is correctly flushed before any connection to avoid particle injection

into the 9245 hydraulic system.

1.

Connect the drain outlet.

2.

Connect the sample inlet/outlets.