Cashco 521 User Manual

Page 9

IOM-521

9

and align ment of parts (10) (8) (11) (7),

re move temporary spacer while continu-

ing downward force on the stem (9) while

si mul ta neous ly holding the bonnet (2) from

drop ping down wards.

13. Lower bonnet (2) carefully downwards into

the recess of the body sub-assembly (1)

while con tin u al ly applying downward force

on the stem (9).

14. At this point, downward force on stem (9)

may be exchanged for down ward force on

the bon net (2). Hand-tighten all bonnet cap

screws (14); relax down ward force on bonnet

once cap screws have taken up all slack.

15. Using a torque wrench, tight en bonnet cap

screws (14) in alternating cross-pat tern in

1/4 rev o lu tion in cre ments to 40 ft-# (55 N-M).

7. Center the loose parts (10) (7) surrounding

the stem (9) as close as possible.

8. Position the bonnet (2) over the exposed

upper stem sub-assembly (9), ensuring

that the anti-rotation "stop" (square or fl at

surface of the stem) is properly en gaged

into the bonnet (2) square recess.

9. Place a temporary spacer device (screw-

driv er blade, nuts, plain washers, etc.)

equallyspaced on the body (1) fl ange to hold

the bonnet (2) up, as bonnet is lowered into

the body, maximizing the gap between the

bonnet fl ang es (1) (2).

10. Place anti-seize thread lubricant on bonnet

cap screws (14). Engage all bonnet cap

screws (14) with lockwashers (13) ap prox i-

mate ly 1-1/2 revolutions.

11. Visually observing the gap between the

bon net (2) lower fl ange surface and the

body sub-assembly (1) bon net fl ange, ap-

ply downward force tend ing to seat the plug

end (3). This will pull the bellows (8.1) into

proper position for the primary bon net seal.

12. When visually satisfi ed of concentricity

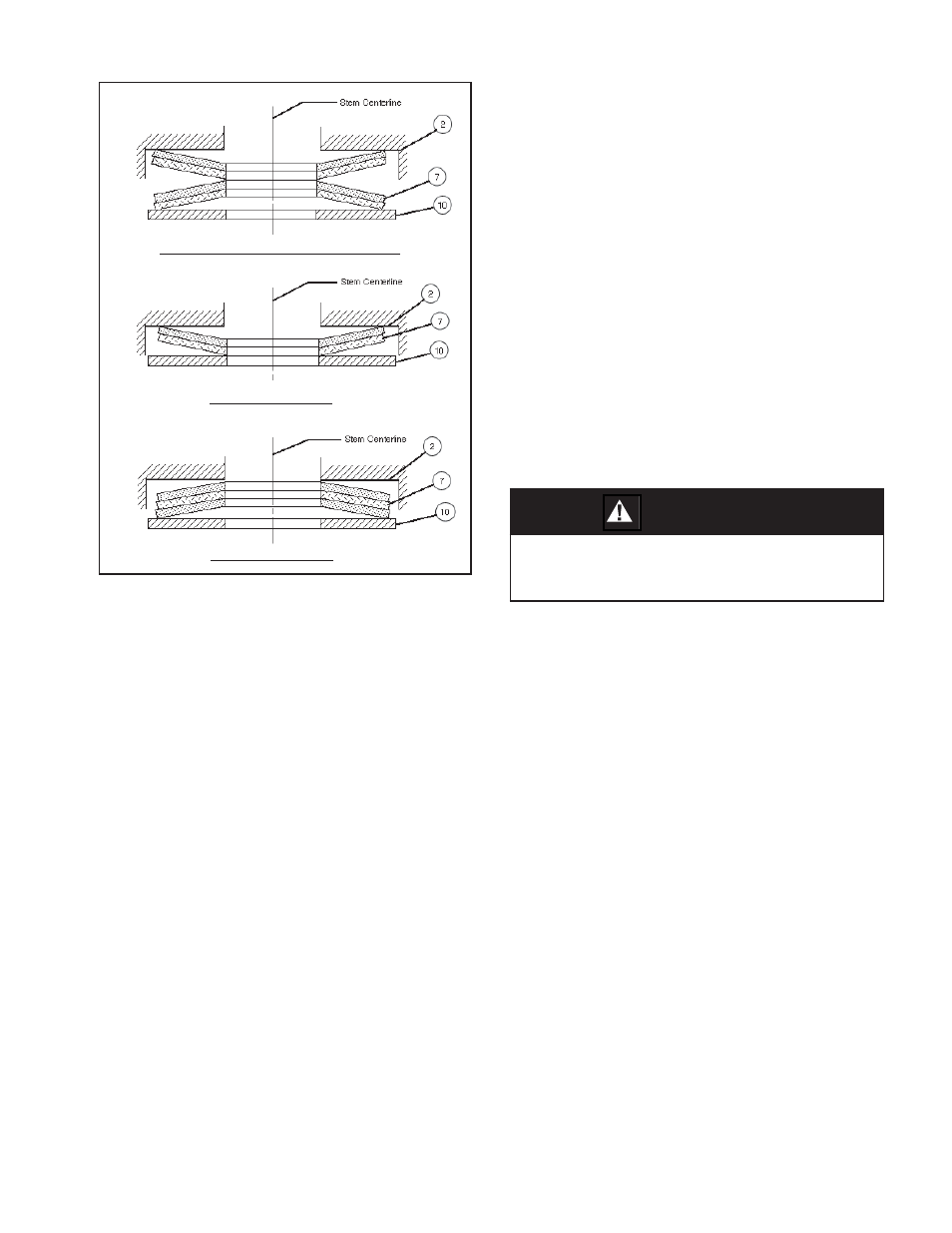

Figure 7: Belleville Spring Washer Orientation

1/2" (DN 15) & 1-1/2" (DN 40) Body Sizes

1" (DN 25) Body Size

2" (DN 50) Body Size

CAUTION

Improper bonnet bolting torques may lead to

premature failure of the primary and secondary

bonnet seals.

16. Engage threaded, vented pipe plug (12) into

the 1/8" NPT tap on the bon net (2) if it was

removed. If a lubricating oil is compatible with

the fl uid, a light coat ing will aid in pre vent ing

galling of the plug (12). En sure that the tip

of the notch on the threads is in the bonnet

(2) at least 1-1⁄2 revolutions. Do not over-

tighten to min i mize chanc es of galling.

Do not use thread sealing com pound that

might “fi ll in” the notch and negate the pur-

pose of the notch.

17. The packing ring set (6) de sign is identical

for all unit body sizes. It consists of seven

V-rings (6.1) and one each male (6.2) and

female (6.3) adapter. (See Figure 8.)

The

purpose of the packing rings (6) is to mini-

mize moisture ingress, and to serve as a

sec ond ary stem seal in the event of bellows

sub-as sem bly (8) failure.

Carefully install rings (6) as indicated in

Fig ure 8, one at a time, using a hollow tool

to press the rings (6) to their fi nal position.

Take care in slipping the rings (6) over the

threaded end of the stem (9) so as to not

mar the ring’s (6) internal surfaces. Do not

reverse ori en ta tion for vacuum service. Do

not “split” rings (6) for ease in replacement.

Do not reuse re moved packing rings (6).