Cashco 521 User Manual

Page 5

IOM-521

5

A. General:

1. Once

fl uid pressure has been iso lat ed by

block valves, and piping fl ange bolting has

been only loos ened, care ful ly re move vented

pipe plug (12) from the bonnet (2), applying

the detection procedures of C. 1. above, as

a small quantity of fl uid may be “trapped” in

the void space of the bellows (8) interior due

to permeation. The plug (12) has a “groove”

notched in its threads to assure venting prior

to the threads fully disengaging. Once fully

vented and/or purged as required by safety

procedures, reinstall the plug (12) using a

fl uid compatible lubricant . DO NOT USE

THREAD SEAL ANT FOR VENT ED PIPE

PLUG (12) ON RE IN STAL LA TION.

2. Maintenance procedures hereinafter are

based upon removal of the valve/actuator

unit from the pipeline where installed.

3. Owner should refer to Owner’s procedures

for re mov al, handling and cleaning of non-

reuseable parts and suitable sol vents, etc.

4. Valves supplied from the factory do not use

any sealing aids for the gasket such as oil,

sealant, or pipe dope in the wetted portions

of the valve body as sem bly. Sealing aids

should not be required and are not rec om-

mend ed.

5. All indicated Item Numbers that are with

re spect to actuator assembly (AA) will be in

pa ren the sis and un der scored; i.e. (20). All

Item Num bers that are with respect to the

body assembly (BA) are not underscored;

i.e. (32). Reference with respect to the

positioner is in double parentheses; i.e.

((AP)).

V. MAINTENANCE

WARNING

Model 521 control valves fre quent ly are installed

in haz ard ous/le thal fl uid ser vic es. Be fore re mov al

from pipe line or any level of dis as sem bly, con sult

the Own er’s safety pro ce dures for proper fl ushing,

clean ing and han dling of a valve ex posed to po-

ten tial ly haz ard ous fl uids dur ing de-pres sur iza tion

and re mov al. Owner's safe ty procedures pre empt

any state ments or rec om men da tions con tained in

this IOM.

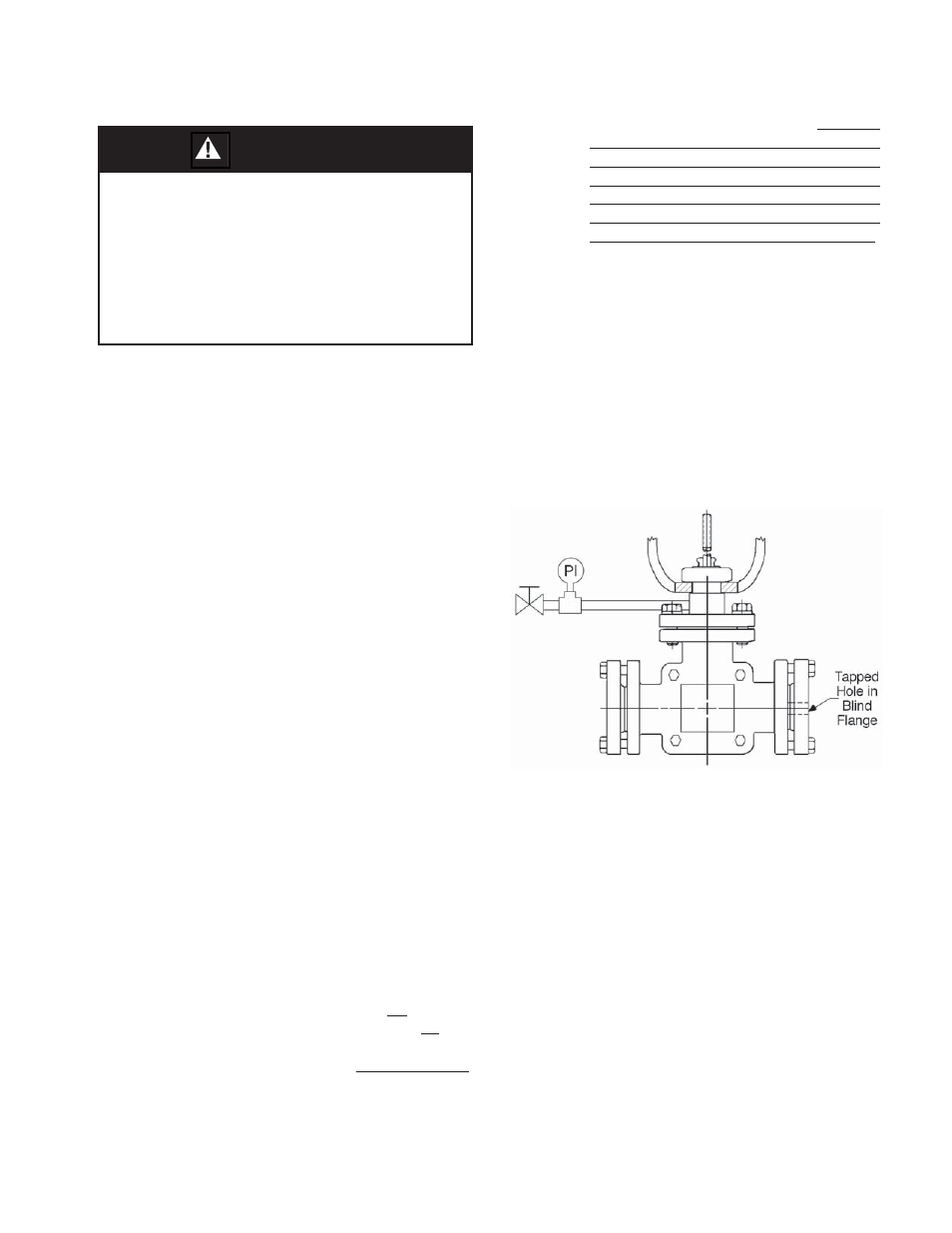

Figure 5: Pressure Boundry Testing Confi guration

SECTION V

6. The stem sub-assembly (9) is designed

for non-rotation when installed. DO NOT

AT TEMPT TO RO TATE WITH THE STEM

SUB-ASSEMBLY IN STALLED; FAILURE

TO HEED MAY CAUSE DAMAGE TO THE

STEM SUB-ASSEMBLY (9), THE BEL-

LOWS SUB-AS SEM BLY (8), THE PLUG

(3) AND/OR THE BODY ASSEMBLY(1).

Exhibit special care when handling the stem

(9) sur face where it contacts the packing

(6).

B. Pressure Boundary Leakage Shop Test:

1. Secure the body assembly (BA) in a vise

with the valve stem (9) oriented vertically.

2. Remove vented pipe plug (12).

3. Install a pipe nipple, test pressure gauge and

isolation valve into the 1/8"-NPT (female)

open ing. (See Figure 5.)

4. Place a suitable adhesive tape (“duct tape”)

around the perimeter of the bonnet/body

fl ange. Place tape on the “joint lines” of the

shell halves (1.1) (see Figure 10). Place blind

fl ang es over the fl anged end connections

and bolt down; one of the blind fl anges must

have a hole thru the face; place tape over

the opening of the blind fl ange.

5. Using a source of acceptable fl uid such as

ni tro gen gas, pressurize the bellows “void

zone” to 30 psig (2.1 Barg). Tightly close off

the isolation valve of 3. above. Disconnect

the pressure source.

6. Poke small holes in the tape at the bonnet/

body fl ange and at the opening in the blind

fl ange.