Cashco 521 User Manual

Page 10

IOM-521

10

4. This procedure assumes that bonnet (2) has

been bolted to the body sub-assembly (1).

5. Engage stem jam nut (20) to body as sem-

bly’s stem (9) by rotating CW (viewed from

valve stem (9) end). Rotate jam nut (20) all

the way to root of the stem (9) threads.

6. Lower actuator assembly (AA) until the

open ing of the actuator yoke (1) is at the

level of jam nut (20).

7. Place yoke nut (15) over valve stem (9) and

lower the nut to rest upon the yoke (3).

8. Push valve stem (9) downward towards

seat ing po si tion. NOTE: The valve bellows

(8) may give “spring action” to keep the plug

(3) par tial ly away from the seat.

9. For Direct Action ATO-FC Only: Connect

a temporary air supply hose that has an

adjustable airset with gauge connected at

the lower actuator inlet. Pressurize actuator

to a suffi cient level to the upper pressure

level of the bench setting; i.e. for 5–15 psig

(.34–1.03 Barg) range, set pres sure at 15

psig (1.03 Barg).

10. Apply Loctite Nickel Anti-Seize to grove and

top surface of swivel lower knuckle. Engage

(slide) the lower knuckle (44) into the upper

knuckle (43) saddle.

11. Continue lowering the actuator assembly

(AA) until the swivel lower knuckle (44)

connector and the valve's stem (9) just

touch. NOTE: For ATO-FC may need to

slowly reduce air pressure in the actuator

to connect the stem and knucle.

12. Thread

yoke

nut (15) onto bonnet (2) threads

by hand as far as possible to help stabilize

topworks. Wrench-tight en one-half (1/2)

extra revolution.

13. Engage valve stem (9) threads to swiv el

lower knuckle (44). Rotate swivel knuckle

(44) CW (viewed from actuator end) to

engage with valve stem (9), refer to V.C.

Steps 9A or 9B for the number of rev o lutions

recorded to dis-engage the lower knuckle.

14. Remove overhead rigging to allow ac tu a tor

assembly (AA) to fully rest on the bonnet (2).

Refer back to V.C. Step 2 for alignment of

match marks. Hand-tighten yoke nut (15).

18. Place anti-seize thread lubricant on threads

of packing gland nut (5). Place gland nut

(5) over the stem (9) end and engage with

the bonnet (2) by rotating CW (viewed from

ex posed stem (9) end); continue fi nger-

tight en ing to the point of resistance. Wrench

tighten gland nut (5) 1/8 revolution past the

manual tightening re sis tance point.

19. Place bonnet spacer (19) down over

threaded portion of the bonnet (2).

20. Valve body assembly (BA) is completed, and

may be pressure tested up to 275 psig x 1.5

= 413 psig (19.0 Barg x 1.5 = 28.5 Barg) at

ambient tem per a ture. Before pressurizing

for hydro, ensure that plug (3) is away from

body (1) seat. NOTE: Use soft gas kets on

body as sem bly (BA) end fl anges to prevent

dis tor tion of TFE fl ange fac ings.

H. Mounting Actuator Assembly to Body

Assembly:

1. Reference Actuator IOM-C27-C53 for item

number call outs and drawings for actuator.

This procedure assumes that accessory

plate ((AP)) or indicating washer (51) was

not removed or has been secured to the

actuator stem(6) by the swivel upper knuckle

(43) - tighten with 20-30 ft.lbs. (27-40 N M).

DO NOT allow actuator stem (6) to rotate.

Secure fl ats on bottom of stem (6) when

rotating knuckle (43).

2. Secure the body as sem bly (BA) in a vise

with the valve stem (9) oriented vertically.

3. Rig actuator assembly (AA) to be supported

from above.

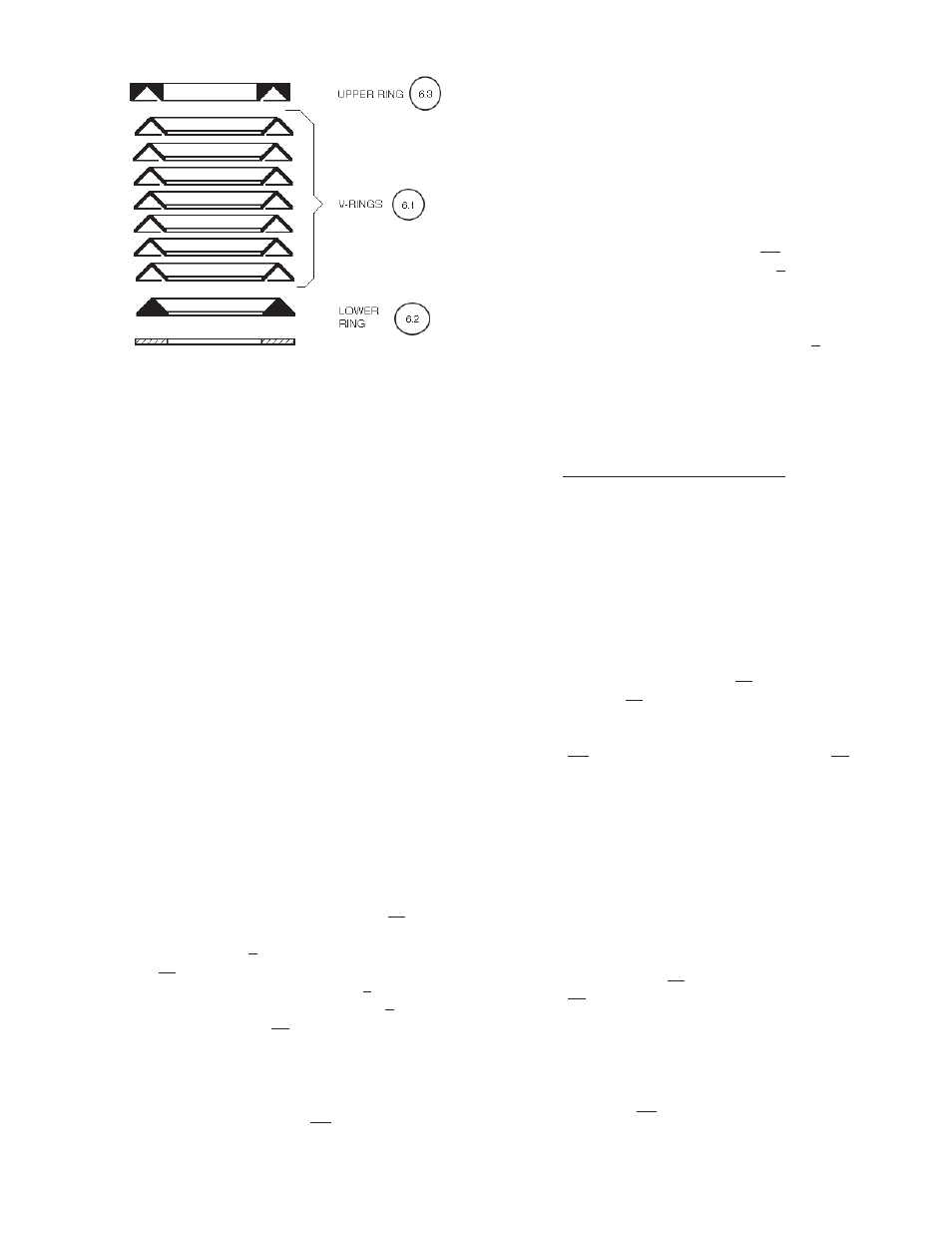

Figure 8: Packing Ring Set